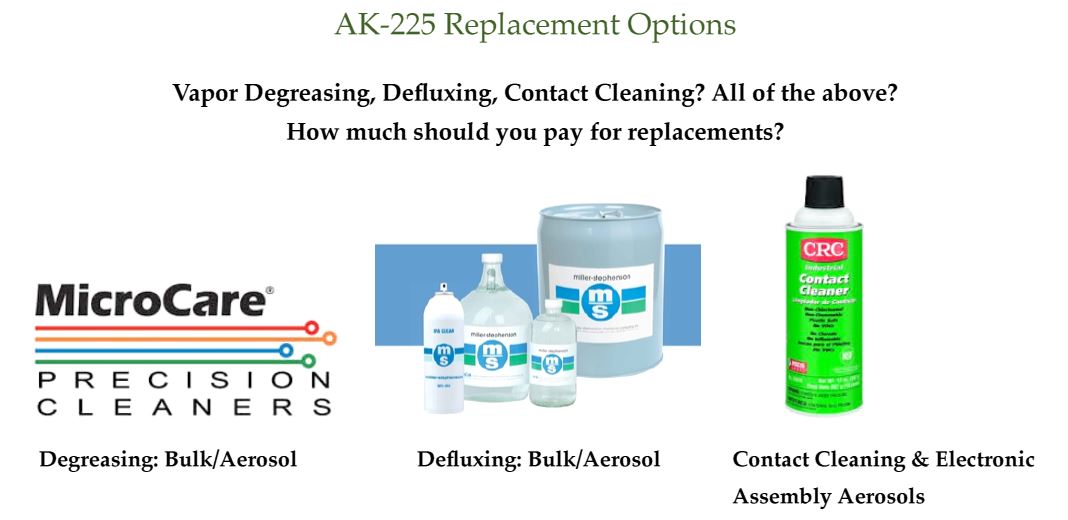

Asahiklin (AK225) was banned from production and import in the United States, effective January 1st, 2015. If your business is still relying on AK-225 (Asahiklin) for cleaning and degreasing, there’s no need to panic—but it is time to plan your transition. With...