Differences Between Deionized Water and Distilled Water

Water is a tricky topic. From filtration method to purity level, it’s hard to know exactly what type of water is right for your needs. Two specific kinds of water, deionized and distilled, are very similar in some ways but also hold several key differences. Both deionized water (aka DI water or demineralized water) and distilled water are extremely pure types of water.

However, their production is very different. Depending on what water is selected for purification, DI water may actually be less pure than distilled. That being said, purity does not always equal better water, and there are pros and cons to choosing deionized water versus distilled water for certain processes.

What is Distilled Water?

This type of water is boiled into purification and thus contains no impurities or contaminants. Unpurified water contains things like:

- chlorine

- iron

- sulfates

- dissolved solids

While this sounds like a great idea for safer drinking water, it may actually do more harm than good in the long run. The distilling process removes most of the natural, helpful minerals from water, making this an unideal candidate for daily consumption.

Although it’s not the best option for daily drinking, distilled water can be used around the house for many things. Some common uses include:

- health equipment, like CPAP machines

- humidifiers

- irons

- aquariums

- watering houseplants

- car care

What is Deionized Water?

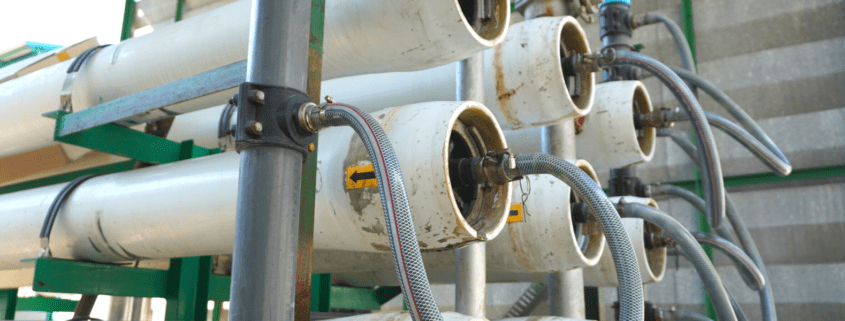

Like distilled water, DI water is very pure. Demineralized water is stripped of all ions. This is done through a process involving electrically charged resins and involves rinsing the water through these resins to completely remove all cations (positively charged ions) and anions (negatively charged ions). Usually, DI water is created using both the charged resins and a process called reverse osmosis to completely eliminate the desired contaminants.

DI water is sometimes referred to as demineralized water because, like its distilled counterpart, most of the minerals found in water are stripped during the deionization process. This means that this type of water, like distilled, is not the best option for drinking use because it does not contain the beneficial nutrients we get from unprocessed water.

Demineralized water is typically used in laboratory settings or pharmaceutical settings when it is necessary that the water be 100% pure. The reason for this is that pure water yields predictable and repeatable results. It can also be used in the home in the same ways as distilled water.

What’s the Difference between Deionized Water & Distilled Water?

Even with all this information, it can still be tricky to pinpoint the exact differences when it comes to deionized water versus distilled water. The main difference is that distilled water contains fewer organic impurities and contaminants because the boiling process kills molecules like viruses and bacteria. Deionized water also has a cleaner production process and leaves behind less residue when used in the desired applications.

Need Water Treatment Chemicals for Deionized Water?

Ecolink offers the highest quality products at affordable prices in bulk, eco-friendly quantities. For more information, contact our team here!