What Does Low VOC Mean?

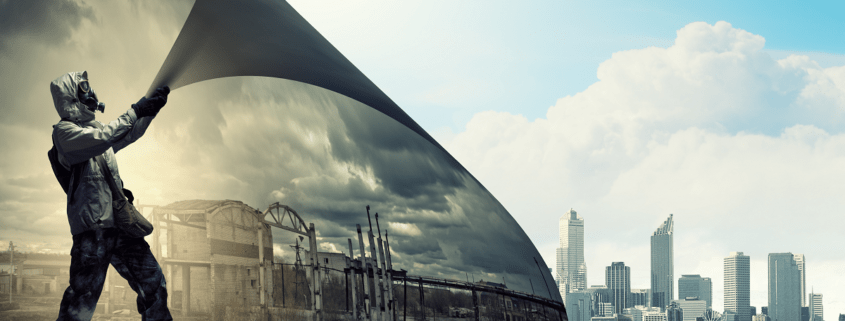

What does low VOC mean? Low VOC refers to low volatile organic compounds. These are chemicals that have a low toxicity level, which is safer for both the user and the environment. VOCs if not handled properly can cause illness and injury to the user, or have a negative impact on the environment. Some states have even placed bans and restrictions on some VOCs like MEK and mineral spirits. If you are looking for low VOC chemical alternatives that are both safer to use, and better for the environment, you should consider green chemical alternatives.

Green chemical alternatives, or environmentally preferred chemical alternatives are low VOC and can accomplish many of the same tasks that traditional chemicals are used for. Practices like parts washing, metal working, industrial cleaning and more can all benefit from the use of low voc, environmentally preferred, chemical alternatives.

So what does low voc mean? Low VOC chemicals and chemical alternatives are simply low toxicity chemicals and solvents that are healthier for your employees and the environment. If you are interested in working with a chemical supplier that can help you find the right low VOC solutions for your needs, Ecolink can help.

How Can Ecolink Help You?

- Expert Knowledge – Whether you are looking for traditional industrial chemicals, low VOC chemicals, or green chemical alternatives, Ecolink can help. Ecolink has a dedicated team of chemical experts who will work with you to assess your needs and find the perfect chemical to get the job done.

- Bulk Sizing –Ecolink offers convenient bulk sizing including 5 gallon buckets and 55 gallon drums, which provide the added benefit of bulk pricing.

- High Quality – For 30 years, Ecolink has been supplying safe, stable, high quality chemicals for an affordable price. When you work with Ecolink you never have to be concerned about the purity of the chemicals you receive.

What Does Low VOC Mean and Where Can You Learn More?

For more information about low VOCs, chemical solvents, and green chemical alternatives, contact Ecolink here! Ecolink and their team of dedicated professionals are ready to help you find the best solutions for your needs!