Types of Anti foaming Agents

What Are the different types of anti foaming agents and what are they used for? Popular perceptions of anti foaming agents and defoamers are said to include four primary types of anti foaming and defoaming agents. Silicone-free liquid defoamers and anti foaming agents, silicone-based liquid defoamers and anti foaming agents, silicone-free powdered defoamers and anti foaming agents, and silicone-based powdered defoamers and anti foaming agents.

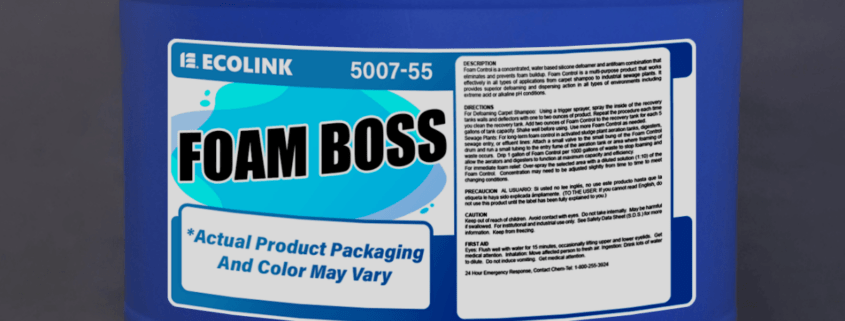

Silicone-free liquid anti foaming agents are typically more effective in water-based and solvent-based systems. Various manufacturers choose silicone-free liquid anti foaming agents because they control the ability of foams to regenerate, are known to not cause discoloration, and are effective in formaldehyde-sensitive environments. Silicone-free anti foaming agent suppliers like Ecolink provide these products to industries that manufacture adhesives, coatings, metal products, paints, resins, rubber, film developing chemicals among others.

Silicone-based liquid anti foaming agents are constructed with functional additives and non-ionic surfactants that are used when making silicone-based liquid anti foaming agents. Many end-users purchase silicone-based liquid anti foaming agents for their surface tension-altering properties. Some industrial users purchase silicone-based liquid anti foaming agents, combining them with hydrophobic solids to increase the anti foaming and defoaming effects.

Some purchasers choose silicone-free powdered anti foaming agents for cement mixtures, wettable agrochemical powders, and dry flowable agrochemicals. Silicone-free powdered anti foaming agents are widely sought after for their competitive cost and work efficiencies while being able to be stably stored.

Silicone-based powdered anti foaming agents are constructed from silicone-based anti foaming compounds. They are used in many and varied industries including adhesives, agriculture, construction, detergents, oil refining, paints, inks, coatings, and textiles for their lasting anti foaming and defoaming power and stability in small concentrations.

Benefits of Shopping for Anti Foaming Agents With Ecolink

- Variety – Ecolink offers several different types of anti foaming agents and a wide range of chemicals, solvents, parts washers, green chemical alternatives, and more, to serve as a one-stop shop for all your chemical needs.

- Bulk Availability – Ecolink also offers convenient bulk sizing including 5-gallon buckets and 55- gallon drums to ensure you always have enough of the chemicals you need and provide the added benefits of bulk pricing.

- Expert Knowledge – Ecolink and its team of expert chemists have over 30 years of knowledge and experience. They will take time to understand your practice and help you find the best chemicals for your particular needs.

- Eco-Friendly – When you work with Ecolink you can rest assured that not only are you receiving high-quality chemicals, but you are also working with an environmentally responsible company. Ecolink offers a large selection of green chemical alternatives that work just as well as traditional chemicals. Ecolink can also provide you with resources for chemical recycling.

Need To Find The Right Types of Anti Foaming Agents For Your Facility?

If you are looking for high-quality anti foaming agents in bulk, contact Ecolink here! Ecolink and its dedicated team of experts are ready to help!