IPA For 3D Printing

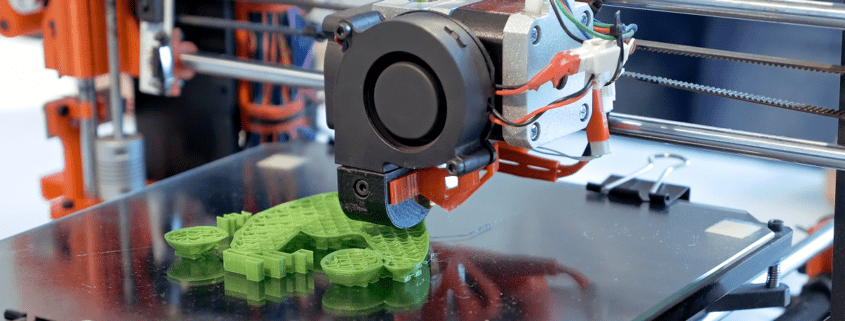

3D printing is a very tedious process that requires some clean-up when it is done. In the most simplistic definition, 3D printing is the process done through a computer program that constructs what you wish to be printed from that.

Going about cleaning a 3D printing can be confusing for some people, so I’m here to give you an option for getting your printer the cleaner it needs!

What is IPA?

Isopropyl alcohol is a widely used cleaning solvent and can clean many different pieces of equipment and remove a variety of stains or hard to remove spills. It’s commonly used as a cleaning source for electronics and metals. Similarly, it can be used in cleaning printing equipment as well. It helps in cleaning resin spills.

3D Printing Relative to Now

In our ever-changing complicated world having a reliable cleaner for 3D printers is important to constantly be able to use equipment properly. 3D Printing has evolved during the COVID-19 pandemic into a crucial tool to help mass produce when other companies can’t to almost anyone in the world. Having a reliable cleaner like IPA for your 3D printer can help your company or your own personal equipment better function without clogging or any other problems that would arise.

3D Printed Products for the pandemic include:

- Medical Devices

- Testing Devices and Equipment

- PPE

- Personal protections (not medical related)

- Emergency rooms

While some of the uses are more at a higher level than personal, IPA can be used to clean all the different types of 3D Printers that produce these many products. If you or someone you know could benefit from a product like IPA to help clean the resin from their 3D printers, you can view some of our available products for you here.