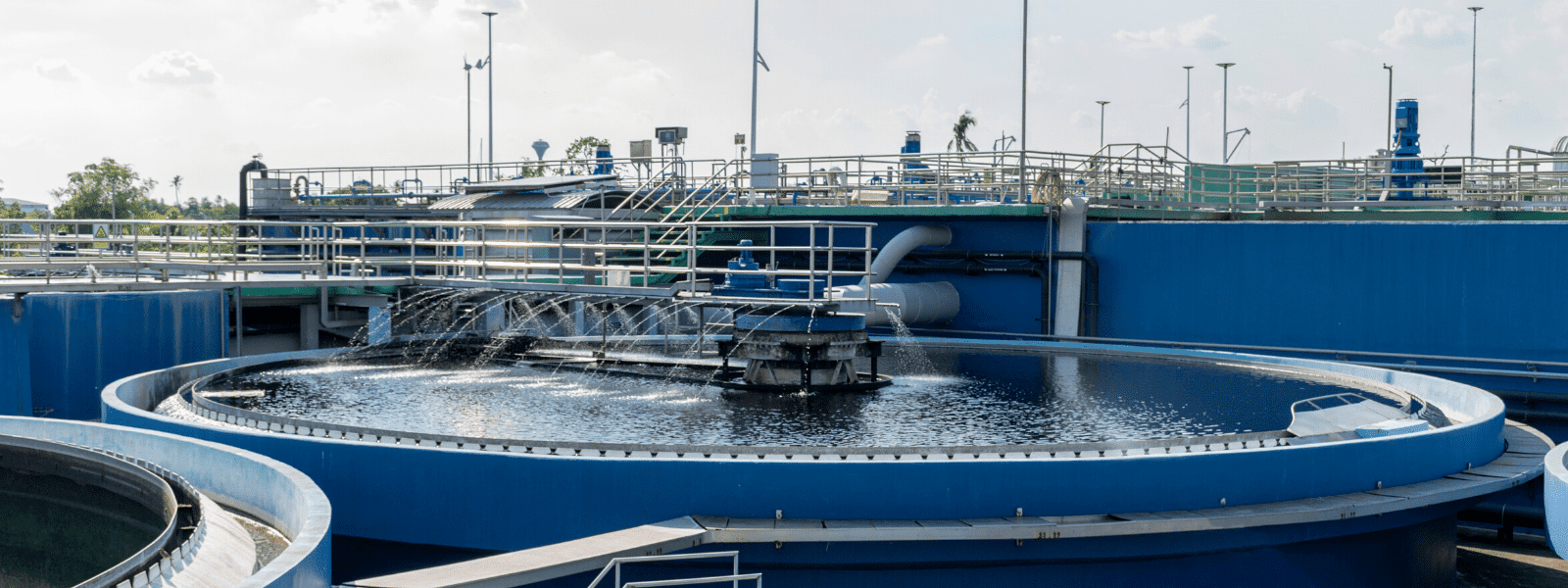

Water treatment follows a process of four steps. Follow along with the Ecolink team as we walk you through the 4 steps of water treatment. If you already know what you’re looking for, click show now below to browse our product selection!

The four most common steps of water treatment include:

- Coagulation and Flocculation

- Sedimentation

- Filtration

- Disinfection

A breakdown of each of the four steps in the water treatment process is described below. Additional steps may be added depending on the final use of the water.

-

Coagulation and Flocculation

Coagulation is the first step in water treatment and uses positively charged chemicals added to the water to neutralize negative charges held by solids. After neutralization, smaller particles bind with the added chemicals to form larger particles.

Flocculation follows coagulation. The larger particles formed from coagulation begin a gentle mixing process, called flocculation. The larger particles collide, binding with each other to form larger, visible particles called flocs. They continue to grow as mixing continues until they reach an optimal size for the next step in water treatment.

-

Sedimentation

The floc and water mixture from the previous step is held in a tank to give the suspended particles time to settle due to the bottom of the tank due to gravity. The more time the water is undisturbed, the more particles will settle. Coagulation and flocculation make the sedimentation process more effective in separating since it increases the size of the particles.

-

Filtration

After sedimentation occurs, the water is almost clear. Filtration is used to remove the smaller dissolved particles that are in the clear water. Some types of dissolved particles include:

- Dust

- Chemicals

- Bacteria

- Parasites

To filter out the dissolved particles, the water is passed through materials that vary in size and composition. Common materials used are sand, charcoal, and gravel. The flow rate of water is dependent on what is expected to be removed from the water using specific materials.

- Disinfection

The final stage of water treatment involves adding a disinfectant to the water. The purpose of disinfection is to oxidize and eliminate any remaining organic matter to prevent the spread of bacteria and parasites. Disinfection also helps protect the water from other bacteria it may encounter during distribution.

Looking for Water Treatment Chemicals?

Ecolink can improve your water treatment! Contact us to learn what chemicals best fit your need!