In everyday life, it’s common to not be able to get the products and supplies a consumer needs due to the many supply chain disruptions our world is currently facing. No one has been untouched by the supply chain disruptions from regular everyday consumer products to the automobile industry because of the COVID-19 Pandemic. Now it’s time for us to take a further look into supply chain chaos in the past and how it’s affecting places like the chemical industry now.

Chemical Supply Chain Disruptions: A History of

As a world, there are many instances in which disruptions have taken place, and they come in many forms from production, transportation, supplies, consumer demand, and shortages. How do disruptions like these come about? It can emerge from anything like weather-related disasters, to consumer protests, and even like most recently, trucker protests in Canada that have barred trucks from making it to the United States and disrupting cross-border trading efforts.

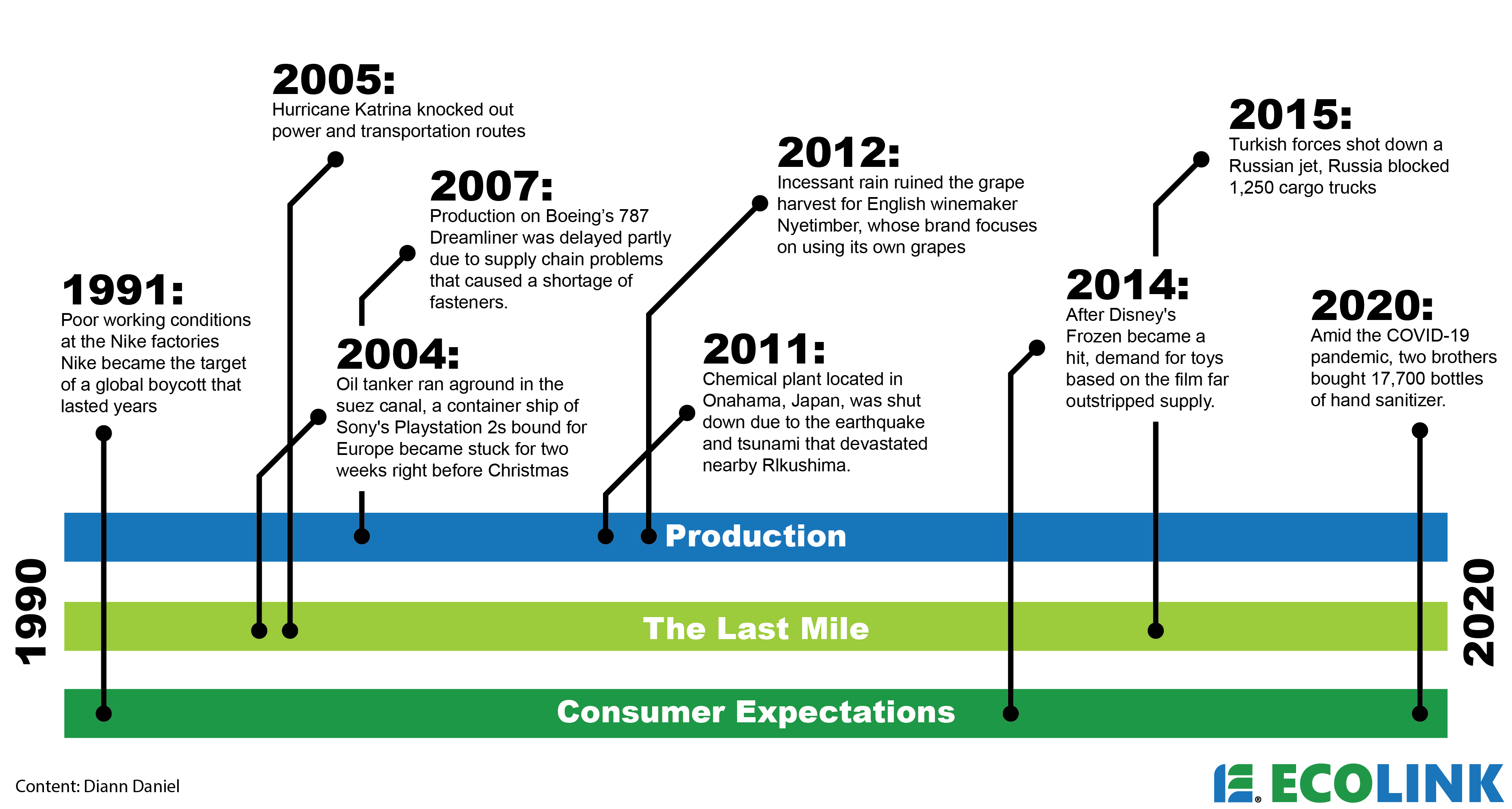

Figure 1 below shows in detail the many ways in which supply chain disruptions have taken place in all its many forms.

Figure 1. History of Supply Chain Disruptions (Diann Daniel)

Most notable in terms of supply chain disruption was Hurricane Katrina, which ravaged the Gulf of Mexico back in 2005 causing shockwaves that were felt up the Mississippi River and across the nation. Though, Hurricane Katrina brought to light how unprepared businesses and consumers were for such a large disaster that it set a precedent for how we look at supply chain disruptions even today. For example, when Texas was hit with an unforeseen polar vortex.

Economic Factors Affecting Supply Chain

Economic shifts are also a means of supply chain disruptions. Looking at the 2016 Brexit event, when the UK left the EU there were many changes made to the supply chain after that dramatic shift in economics. Seeing how different kinds of environmental factors affect supply chains, with the recent COVID-19 pandemic taking place, how is the chemical industry being impacted by COVID-19 supply chain disruptions?

The Chemical Industry and COVID-19 Disruptions

Chemical companies and the chemical industry overall have been greatly affected by the COVID-19 pandemic. Before we can examine the effects on the chemical industry, we must look at supply chains overall.

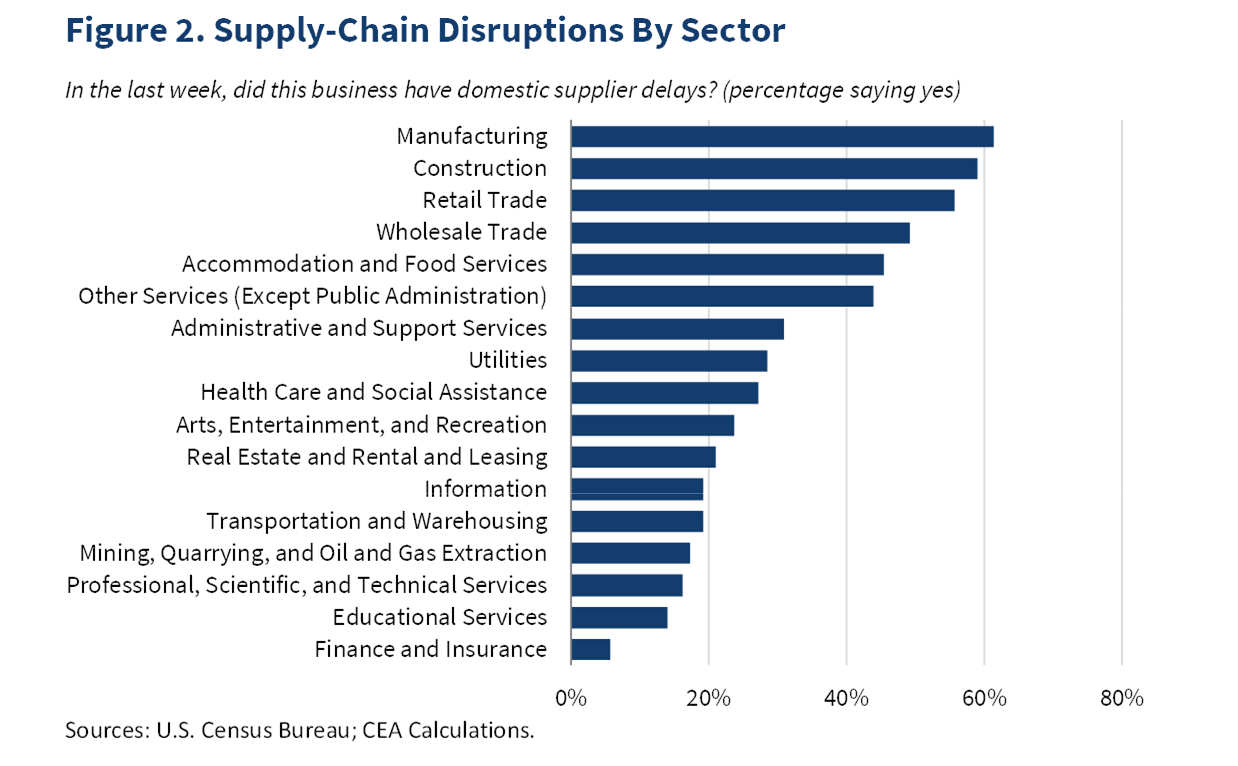

During the pandemic, businesses had way too much stock as consumers cut back on spending and tightened budgets due to lay-offs and job losses. Businesses were able to liquidate inventories and cut their losses. But as consumers reentered the markets and began resuming their previous purchasing habits, businesses inventories could not make the demand. In the U.S. Census Small business survey, it was found that about 36% of small businesses reported shipping delays because of their suppliers. Figure 2 below outlines industries’ supplier supply chain disruptions because of the COVID-19 pandemic.

Figure 2. Disruptions by Industry (U.S. Census Bureau)

Figure 2. Disruptions by Industry (U.S. Census Bureau)

More About the Chemical Industry

Seeing sectors like transportation and warehousing sitting at almost 20% shows a correlation to the chemical industries and the transportation of chemicals to manufacturers. A key takeaway from an NACD Shipping Survey concluded that in June 2021, 84.5% of chemical distributors reported that they were out of some products with a potential of that number going up to 92%. Take into account as well that this survey was conducted well before the holiday season and there is no follow-up study to reflect those statistics.

As 2022 continues, supply chain issues will continue to worsen for chemical manufacturers as the COVID-19 pandemic rages on. The COVID-19 pandemic has caused manufacturers and businesses to modify their operation processes because of supply chain disruptions. Things like raw materials needed to make chemical products have been affected the most because of shortages and the increased transit costs because of supply chain demands and lack of drivers

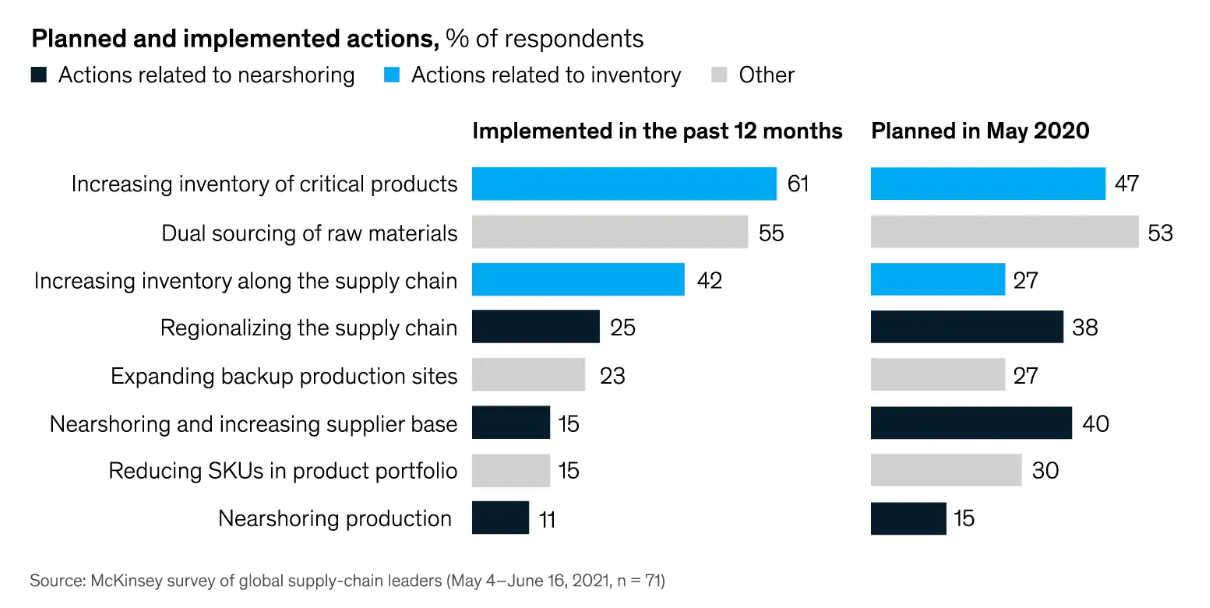

Also, to keep up with these rapid changes of demand in the chemical markets, over 1 million drivers need to be hired to keep up with the rapid demand. In terms of shortages of raw materials, companies are taking other steps to counteract the effects of supply chain disruptions. Figure 3 below shows how companies overall planned activities in May of 2020 versus June of 2021.

Figure 3. Supply Chain 2020 and 2021 (McKinsey)

Furthermore, chemical industries and more are making constant shifts to counter supply chain disruptions and work to find new ways to support business and facilitate sales. Businesses and consumers alike can now ask the question if they’re learning how to make changes now, how can they continue to avoid situations like this in the future?

How to Avoid Issues in the Future?

How are situations like this avoided in the future? Risk managers help provide valuable insight into how businesses can better themselves in the event of the past. There are around five ways in which risk managers have found that businesses can look to, to make sure events like these are preplanned for, some of those suggestions are:

-

Quantifying Risk

Meaning to look at risks already identified for the future and find the right data to help in the decision-making processes. Quantifying risk can also be looking at risk and the interactions those risks may have and looking at all outcomes that could take place.

-

Planning Situations

This goes beyond looking at the outcomes of risks. Planning scenarios suggest looking at all the parts of your supply chain and transport and evaluating all your processes as they would happen through different scenarios.

-

Network Building

The world is better when we all work together. To work to prevent future supply chain disruptions, businesses and companies must build networks full of elements from all parts of the supply chain to work on risk management strategies together.

-

Sharing Information

The many processes of working through the network of the supply chain to share what everyone knows about their duties. Furthermore, data sharing ensures open knowledge to all networks. This way there can be a standard built between parts of the supply chain to help lessen the impact of future disasters.

-

Public and Private Matters

Stakeholders have a large impact on the businesses they support. Keeping an open transparent line of communication with stakeholders is important. Therefore, businesses can keep good relationships and build better trust with stakeholders.

Looking For Chemical Supply Chain Transparency?

Here at Ecolink, Inc we work to provide the utmost transparency about the situation of our supply chains and inventory. As a company, we work to find whatever ways possible to find the product that you need for your business. Having risk managers on staff here at Ecolink, we work constantly to make sure we have the right plans in place in case of emergencies.

Consistently as a company, we make sure to keep our website and social media platforms with the most updated information we can ensure you are aware of the status of the products we have.

For more information about how we are handling supply chain disruptions or questions about how we can help you find a product that has been disrupted by supply chains contact us here today! We look forward to hearing from you soon!

Ecolink Community Updates

Interested in more in the Ecolink Community? You can read one of our other community blogs here! Stay tuned for Ecolink Community blogs in the future by checking us out on social media! There you’ll be able to keep up with our latest community updates and blogs!