For most solvent cleaners ? industrial strength and otherwise ? a non-residue formulation, which means the cleaner leaves no residue after performing the cleaning action, is generally considered a good thing. Some cleaners purposefully leave residue to help protect the equipment or part’s final application, such as to provide a buffer against a certain chemical.

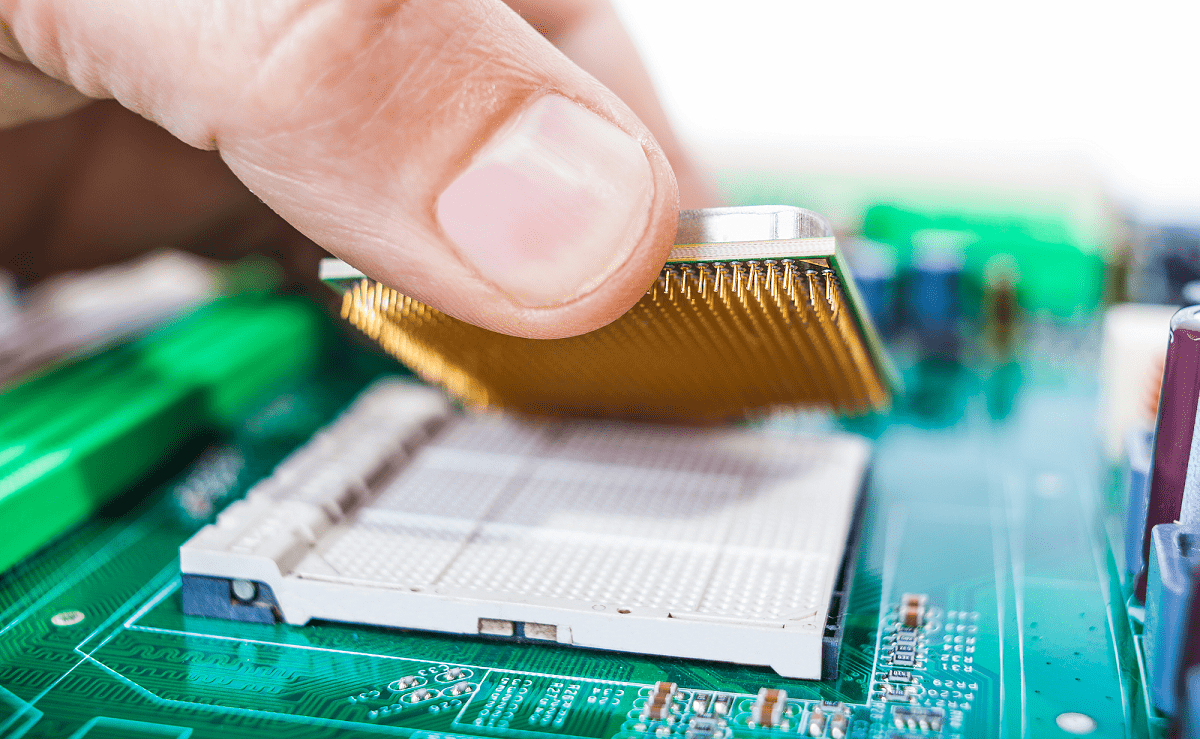

In most instances, however, using residue free solvents is considered the best option, especially when cleaning electronics. To understand the value of residue free solvents as electronic cleaners, it helps to consider what may happen if electronic equipment were cleaned with a residual solvent instead.

Residual Solvents and Electronics

Solvents that leave a residue pose three general problems for electronic equipment, although some problems are limited to particular equipment construction features. Without getting too complicated, let’s take a look at problems residual solvents commonly pose to electronics.

1. Residue Impedes Electrical Current

Especially when they contain a dielectric, solvents that leave a residue can imeded electrical current in the equipment they clean. Primary areas of considerations are electrical contacts and printed circuit boards. If you find your electronics don’t work efficiently after using a residual dielectric cleaner to service them, the dielectric material in the residue could be the culprit.

2. Attracts Dirt and Grime to Parts

If you leave a film of soap residue on a kitchen floor after mopping, you’re working at cross purposes. You’re trying to clean the floor, but the residue will attract dirt and grime faster than a floor treated with residue free solvents. Bottom line: You’ll need to clean more often.

The same thing can happen to electrical equipment. To make matters worse, the equipment often features geometrically complex parts in close fitment, offering plenty of seams and crevices for residue to collect unhindered, until a residue removal operation is performed.

3. Can Sabotage Moving Parts

This concern deals primarily with motors, which, when in motion, must have proper oil viscosity to prevent moving parts from grinding on each other. The layer of oil between moving parts is exceptionally thin, and introducing solvent residue to the mix could ruin viscosity, making it too thick. Letting the problem persist for even a few minutes could cause significant damage.

Need Residue Free Solvents?

If so, Ecolink has a wide range of environmentally preferred solvents that are designed to clean electronics, without leaving a trace of residue that could importune the equipment’s operation. One of our eco-friendly stock products may be perfect for you requirements. If not, we can create a custom solvent that matches your needs, and supply it on an ongoing basis.

To request a free product sample or place an order, please call us today at 800-563-1305, or reach us through our contact form. We look forward to providing residue free solvents!