Environmental-Preferred Alternatives to MIL-PRF-680/P-D-680 Cleaner

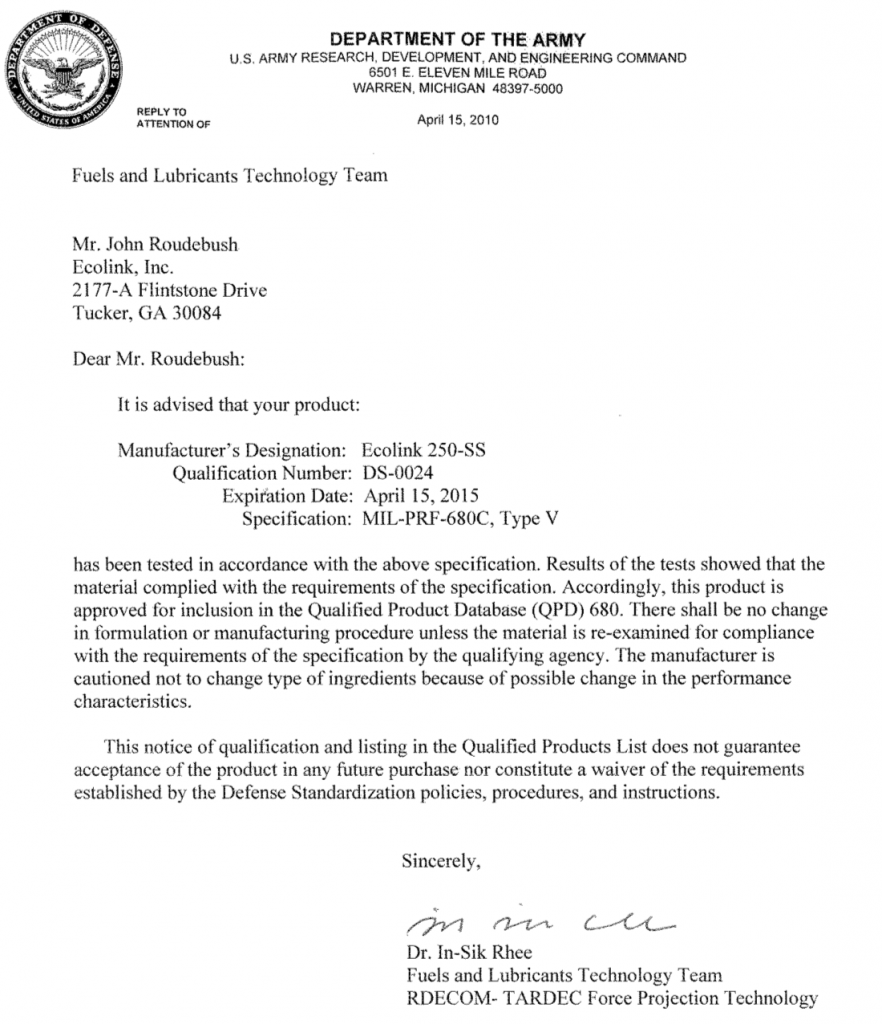

Before you consider buying Safety Kleen’s QSOL 300, stop and consider your choices. While 1 of 3 approved prodcuts per the attached article recently published there are more alternatives under review. Effective April 15, 2010 Ecolink Inc. is the ONLY approved alternative to MIL PRF 680B with MIL PRF 680C Type V. This option is ideal for areas requiring LOW VOC solvents. Call 800 886-8240 or email info@ecolink.com.

March – April HTIS Bulletin

By Hem L. Tripathi, Chemical Engineer, Hazardous Minimization and Green Products, DSCR

Three products are now available that meet the requirements of MIL-PRF-32295 (Cleaner, Non-Aqueous, Low-VOC, HAP-Free). These field tested products are on a Qualified Products List (QPL), and can be used to clean weapon systems across DOD maintenance facilities as alternatives to MIL-PRF-680. Furthermore, they are less hazardous, safer to use and environmentally compliant.

Three National Stock Numbers (6850-01-576-2676 (1GL), 6850-01-576-2765 (5 GL CO) and 6850-01-576-2736 (55 GL DR) are assigned and authorized for use against the Type I requirements of MIL-PRF-32295.

In August 2007, the Defense Supply Center Richmond (DSCR) initiated a program to find chemical alternatives for the MIL-PRF-680/P-D-680 specifications. These specifications contain volatile organic compounds (VOCs) that affect human health and impact the environment. VOCs are organic chemical compounds that have sufficiently high vapor pressures under normal conditions to significantly vaporize, thereby entering the atmosphere. They are released during cleaning operations and contribute to the formation of ground-level ozone (photochemical smog), damage vegetation, and potentially harm the lungs, liver and kidneys. The United States Environmental Protection Agency (EPA) regulates VOCs in the air, water, and the land.

MIL-PRF-680 and P-D-680 establish the requirements for the hydrocarbon-based solvents used for degreasing and cleaning machine parts of aircraft as well as the support equipment for maintenance. There is no commercial specification available to cover these military applications.

The qualified products for MIL-PRF-680 and P-D-680 have VOC content of more than 750 grams per liter, well above the currently regulated level in certain states. Solvent emissions are regulated locally as well as regionally, and the air pollution control districts in California have the most stringent requirements. Several years ago, the San Joaquin Valley Air Pollution Control District (SJVAPCD) imposed restrictions limiting the VOC content in solvents to no greater than 25 grams per liter for immersion cleaning processes (unless the solvent is used in an airtight cleaning system). Under this new rule, MIL-PRF-680 could no longer be allowed in solvent degreasing operations in the SJVAPCD. Since MIL-PRF-680 and P-D-680 were the only materials authorized by the applicable maintenance manuals to clean engine parts, an approved alternative was necessary to meet the new environmental regulations.

To identify solvent(s) that were less hazardous, safer to use, and environmentally compliant, DSCR’s Hazardous Material Minimization Program branch initiated a collaborative program with the Naval Air Systems Command (NAVAIR), Materials Engineering Division at Patuxent River, MD. The program effort was divided into three major elements: 1) development of the specification, 2) laboratory testing of potential alternatives on cleaning performance as well as material compatibility, and 3) field testing of alternatives with authentic parts.

NAVAIR developed a new specification, MIL-PRF-32295, titled, “Cleaner, Non-Aqueous, Low-VOC, HAP-Free,” and published it on November 5, 2008, for cleaning aircraft components, ground support equipment, and other general applications. Since the Aerospace National Emission Standards for Hazardous Air Pollutants (NESHAP) states that immersion-cleaning solvents and wipe-cleaning solvents must have vapor pressures less than 7 mm Hg and 45 mm Hg respectively, these limits were used to distinguish between Type I and Type II products. The cleaning effectiveness of the tested candidates led to further describing Type I products as being suitable for cleaning light soils such as oils and hydraulic fluids, and Type II products as being suitable for cleaning heavy soils such as greases and carbon residues. The new specification required that the solvent(s) be free of hazardous air pollutants (HAP), effective on grease and oil, non-toxic, compatible with metals and non-metals, and safe to use. It also could not contain more than 25 grams per liter of VOCs, and also be free of ozone depleting substances.

After a thorough evaluation of numerous commercially available products, NavAir’s Materials Engineering Division selected five products for laboratory testing by its Industrial and Operational Chemicals, Material Engineering Laboratories. These cleaners then were tested for cleaning efficiency, material compatibility, corrosion, hydrogen-embrittlement, and the other tests as required by the specification. Of the five selected, three products (QSOL 300, Cyclo-147F, and SB32) met the Type 1 requirements of MIL-PRF-32295 .These products have vapor pressures as low as 1 mmHg, zero VOC contents; and meet the most stringent environmental regulatory requirements. Research is in progress to find products that meet the specification’s Type II.

Field testing the cleaners involved determining the cleaning performance of the three candidates at various military sites (Navy, Air Force, US Marine Corps, and US Coast Guard) on authentic dirty parts associated with different weapon systems. Each cleaning solvent was tested side-by-side against the current MIL-PRF-680 Type II solvent for the duration of the test (that involved cleaning identical parts). Based on the specific cleaning application, the candidates were utilized in various cleaning techniques, brush, immersion, and wipe-cleaning. Photographs of the parts were taken before and after cleaning to compare the effectiveness of the tested cleaners to the control. Listed below are the cleaners that provided successful results with positive feedback.

For additional information on these studies, contact:

Dr. Hem L. Tripathi

Hazardous Minimization & Green Products Branch, Defense Supply Center Richmond, Richmond, VA 23297.

PH: 804-279-5727

eMail: hem.tripathi@dla.mil; or,

Dr. El Sayed Arafat

Materials Engineering Division, Naval Air Systems Command (NAVAIR)

Patuxent River, MD

PH: 301.342.8054

eMail: elsayed.arafat@navy.mil.