Volatile Organic Compounds, also called by their acronym VOCs, are chemicals that have a considerably high vapor pressure even in ordinary room temperatures. The high vapor pressure is a result of having a low boiling point, which in turn causes molecules to be released into the air.  While not all VOC’s are harmful, there are plenty of VOC’s that are considered hazardous, consequently leading to negative effects on people who are in close proximity or come into contact with the noxious gases, as well as having negative consequences on the environment. Dangerous VOCs are classified as “high Volatile Organic Compounds,” whereas the non-hazardous ones are called “low Volatile Organic Compounds.” Even today, with the finding of green alternative industrial cleaners that have a low VOC count, some industrial companies are still using chemical compounds with a high VOC count, and are placing its workers at risk as well as hurting the environment.

While not all VOC’s are harmful, there are plenty of VOC’s that are considered hazardous, consequently leading to negative effects on people who are in close proximity or come into contact with the noxious gases, as well as having negative consequences on the environment. Dangerous VOCs are classified as “high Volatile Organic Compounds,” whereas the non-hazardous ones are called “low Volatile Organic Compounds.” Even today, with the finding of green alternative industrial cleaners that have a low VOC count, some industrial companies are still using chemical compounds with a high VOC count, and are placing its workers at risk as well as hurting the environment.

Safety consultants, such as those found at Ecolink, have been working hard to inform and educate industrial businesses of the potential ramifications of continued use of high VOC cleaners, of which include injuries to employees and severe penalties, such as large fines and the shutting down of your business. For whatever reason, some businesses still have not come around to the fact that low VOC cleaners are available that clean and degrease parts, metals, and materials as well as, even better than any industrial cleaners on the market. There are numerous low VOC cleaners that safety consultants would love to tell these industrial businesses about, and then effectively help those organizations transition away from high VOC cleaners that harm people and the environment.

If you are an industrial business that uses industrial cleaners to rid your products of dirt, dust, stains, grime, grease, oils and other particles that could potentially render products ineffective, but are unsure of whether you are using a low of high VOC cleaners, you need to contact a safety consultant such as Ecolink right away.

Ecolink is a business that helps industrial organizations make the change from high VOC cleaners to low VOC cleaners, ultimate placing their employees out of any potential dangers and keeping the environment clean and healthy. Ecolink has been in the business of helping these types of businesses for years, and they can help you achieve a successful transition to a low VOC cleaner that not only safety consultants will live, but your business will love because it accomplishes a clean that tends to be more efficient than older cleaning agents with a high VOC count.

All it takes is a simple phone call to Ecolink, and their professionals will be happy to evaluate your industrial cleaning solvents. If your company happens to be using a high VOC cleaner, Ecolink professionals will help you switch to a low VOC cleaner that everyone – both safety consultants and the company using the product – can agree on, rely on, and love moving forward.

Low VOC Cleaners that Safety Consultants will Love

/in Low VOC/by Industrial DegreasersVolatile Organic Compounds, also called by their acronym VOCs, are chemicals that have a considerably high vapor pressure even in ordinary room temperatures. The high vapor pressure is a result of having a low boiling point, which in turn causes molecules to be released into the air. While not all VOC’s are harmful, there are plenty of VOC’s that are considered hazardous, consequently leading to negative effects on people who are in close proximity or come into contact with the noxious gases, as well as having negative consequences on the environment. Dangerous VOCs are classified as “high Volatile Organic Compounds,” whereas the non-hazardous ones are called “low Volatile Organic Compounds.” Even today, with the finding of green alternative industrial cleaners that have a low VOC count, some industrial companies are still using chemical compounds with a high VOC count, and are placing its workers at risk as well as hurting the environment.

While not all VOC’s are harmful, there are plenty of VOC’s that are considered hazardous, consequently leading to negative effects on people who are in close proximity or come into contact with the noxious gases, as well as having negative consequences on the environment. Dangerous VOCs are classified as “high Volatile Organic Compounds,” whereas the non-hazardous ones are called “low Volatile Organic Compounds.” Even today, with the finding of green alternative industrial cleaners that have a low VOC count, some industrial companies are still using chemical compounds with a high VOC count, and are placing its workers at risk as well as hurting the environment.

Safety consultants, such as those found at Ecolink, have been working hard to inform and educate industrial businesses of the potential ramifications of continued use of high VOC cleaners, of which include injuries to employees and severe penalties, such as large fines and the shutting down of your business. For whatever reason, some businesses still have not come around to the fact that low VOC cleaners are available that clean and degrease parts, metals, and materials as well as, even better than any industrial cleaners on the market. There are numerous low VOC cleaners that safety consultants would love to tell these industrial businesses about, and then effectively help those organizations transition away from high VOC cleaners that harm people and the environment.

If you are an industrial business that uses industrial cleaners to rid your products of dirt, dust, stains, grime, grease, oils and other particles that could potentially render products ineffective, but are unsure of whether you are using a low of high VOC cleaners, you need to contact a safety consultant such as Ecolink right away.

Ecolink is a business that helps industrial organizations make the change from high VOC cleaners to low VOC cleaners, ultimate placing their employees out of any potential dangers and keeping the environment clean and healthy. Ecolink has been in the business of helping these types of businesses for years, and they can help you achieve a successful transition to a low VOC cleaner that not only safety consultants will live, but your business will love because it accomplishes a clean that tends to be more efficient than older cleaning agents with a high VOC count.

All it takes is a simple phone call to Ecolink, and their professionals will be happy to evaluate your industrial cleaning solvents. If your company happens to be using a high VOC cleaner, Ecolink professionals will help you switch to a low VOC cleaner that everyone – both safety consultants and the company using the product – can agree on, rely on, and love moving forward.

Protecting Workers While Keeping Your Business Clean

/in Eco Friendly/by Industrial DegreasersBusiness owners and executives who understand the fundamental needs to house a prosperous enterprise will tell you that the backbone of any successful company stems from the labor of its workers. Even the minute labor force makes up the building block of creating and nurturing a successful business. It is important that the “higher ups” of a business never forget the importance of every single employee enlisted for duty, as they all play an integral role in ensuring the accomplishments of a company. This is why business owners should do everything within their power to make sure that all employees have favorable working conditions. Employees need to know they are protected and highly thought of, as it makes for morale boosting sentimentality, and subsequently leads to a more enthused and productive work force.

power to make sure that all employees have favorable working conditions. Employees need to know they are protected and highly thought of, as it makes for morale boosting sentimentality, and subsequently leads to a more enthused and productive work force.

As it pertains to industrial businesses that use industrial solvents to clean parts, metals, and materials, business owners of such industrial companies need to make sure that the industrial solutions do not contain hazardous carcinogens and chemical compounds that can serous harm to those who come into contact or are in close proximity to the agents. Unfortunately, many companies still employ the usage of hazardous chemical cleaning components, which means that the workers who are handling the chemical degreasers are putting themselves in harms way, possibly no knowing the potential threats involved. Any company using cleaning solutions for industrial products should contact a company involved in detecting whether industrial businesses are indeed using harmful chemical agents when cleaning products. Ecolink is such a company that can assist businesses in transitioning to a safer chemical solvent.

With green alternative chemical solvents, businesses can protect their workers while keeping their business operations clean. New, eco friendly cleaning agents have proven to effectively clean and degreasers parts, metals, and materials or dirt, dust, stains, grease, oil, and grime as well as, and often times better than older industrial solvents. New, green alternative solutions have been tried and tested, and scientific evidence suggests that eco friendly degreasers rid industrial products of inhibiting agents as efficiently as any industrial solvent on the market. Therefore, all industrial companies contracting the use of cleaning agents can easily, safely, and cost effectively transition to a green alternative solution, all the while protecting workers while keeping the business clean.

Ecolink can educate industrial businesses on the need to switch to a green alternative cleaning solutions, its importance, and that no cleaning efficiency will be lost in the process. Ecolink has a large list of eco friendly cleaning products to choose from and will instruct companies on how to make a quick and easy transition to an eco friendly degreaser. From thereon you will have the knowledge that your industrial business will be protecting its workers while keeping your business clean.

Using Less Cleaning Product Does Not Always Mean Less Clean

/in Eco Friendly/by Industrial DegreasersFor decades, most industrial cleaning products have been effective for companies needing an efficient cleaner for their parts, metals, and materials. Cleaning products are expected to clean and degrease dirt, grime, dust, stains, and oils from products with near one hundred percent efficiency; otherwise, the products might fail when put into production. Industrial cleaners and degreasers have been effective in their duties for quite a long time. Unfortunately, for all of those decades, even centuries, that industrial cleaning solutions have been used, most of them were created with harmful chemical components that were dangerous to both people and to the environment. Because we have the research and necessary science today to test chemical components, there have been a lot of discoveries made concerning industrial solvents and the fact that a lot of them are hazardous to both people and the environment, and can cause serious, and sometimes dire effects on people that could result in death.

Because there have been numerous, and by numerous we mean tens, perhaps hundreds of thousands of cases nationwide, of ailments directly related to exposure to hazardous industrial cleaners that emit noxious gases or are poisonous to the touch, there has been a large push by regulatory committees and green alternative organizations to find and implement safe alternatives. Fortunately, scientists and companies involved in creating green alternative industrial solvents have had monumental success in designing a “less cleaning product.” Make no mistake though, a “less cleaning product” does not mean less clean. It just means using less of the cleaning product to deliver the same or improved results. Reducing the amount of toxicity in a cleaner while improving it’s overall cleaning ability has been the focus of many environmentally conscious chemical companies. Scientists have experienced great success and accomplishment with creating an eco friendly industrial solution that can clean as effectively, if not more effectively than any other industrial solvent ever devised.

The above statement that eco friendly solutions exists that clean parts, metals, and materials as good or better than conventional industrial solvents has been tested and proven by scientists. Therefore, there is no excuse for industrial businesses that use potentially hazardous industrial cleaning products not to transition to a green alternative degreaser, if their company has not already. If you need to make the transition to a less cleaning product, Ecolink can help you identify and incorporate a green alternative solution.

Ecolink has been one of the early pioneers involved in the movement to help industrial businesses that need less toxic cleaning products find an eco friendly alternative to ensure the safety and health of all employees around or near the chemical solvent. An Ecolink professional will help you transition to a safer, less toxic, solvent; and remember, though the new solvent will be considered “less” cleaning, it does not mean your products will be less clean. Conversely, your business will find your parts as clean, or cleaner than your previous solution.

What Does an Industrial Hygienist Do?

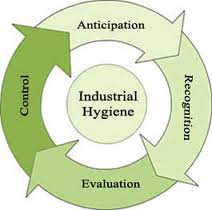

/in Industrial Hygienist/by Industrial DegreasersIndustrial hygiene is the science of anticipating, recognizing, evaluating, and controlling workplace conditions that could cause the injury or illness of a worker. Industrial hygienists use environmental monitoring and analytical methods to detect the extent of worker exposure and employ engineering, work practice controls, and other methods to control potential health hazards. It is the role of the industrial hygienist to identify any ominous conditions that could cause harm to a worker, and alert the business unwittingly placing its workers in nefarious conditions that the conditions need to be changed. If those changes are not put into place that make the conditions better for the worker, the industrial hygienist has the right to expose the unsavory conditions to the proper authorities, so that the business can be forced to fix the conditions, otherwise the company runs the risk of being shut down.

History concerning industrial hygienists and their practices can be dated back to four hundred years B.C., when Hippocrates noted lead toxicity in the mining industry, and the health risks associated with working in such dire conditions. For the sake of brevity, this blog will cover the most recent strides in the profession.

In the early 20th century, and while working in the United States, Dr. Alice Hamilton led efforts to improve industrial hygiene. She observed industrial conditions first hand and startled factory managers, state officials, and mine owners with evidence that there was a correlation between worker illness and their exposure to toxins. She also presented definitive proposals for eliminating unhealthful working conditions.

At about the same time, U.S. federal and state agencies began investigating health conditions in industries deemed the most harmful to its workers. In 1908, the public’s awareness of occupationally related diseases stimulated the passage of compensation acts for certain civil employees. States passed the first workers’ compensation laws in 1911. In addition, in 1913, the New York Department of Labor and the Ohio Department of Health established the first state industrial hygiene programs. All states enacted such legislation by 1948. In most states, there is some compensation coverage for workers contracting occupational diseases.

The U.S. Congress has passed three landmark pieces of legislation relating to safeguarding workers’ health: (1) the Metal and Nonmetallic Mines Safety Act of 1966; (2) the Federal Coal Mine Safety and Health Act of 1969; and (3) the Occupational Safety and Health Act of 1970. Today, nearly every employer is required to implement the elements of industrial hygiene and safety, occupational health, or hazard communication programs, as well as to be responsive to the Occupational Safety and Health Administration (OSHA), the Act put into law, and its regulations.

Safety Act of 1966; (2) the Federal Coal Mine Safety and Health Act of 1969; and (3) the Occupational Safety and Health Act of 1970. Today, nearly every employer is required to implement the elements of industrial hygiene and safety, occupational health, or hazard communication programs, as well as to be responsive to the Occupational Safety and Health Administration (OSHA), the Act put into law, and its regulations.

One area of hygiene every company should review is their use of industrial cleaners and the levels of toxicity they may have. Ecolink is an environmentally conscious company who develops and manufactures chemicals that leave the smallest impact on the people and environment they come in contact with. Contact Ecolink today and one of their professional customer service representatives will be able to recommend cleaning solutions that will clean just as thoroughly as your current cleaners, while keeping workers safe.

Reducing Worker Exposure to Toxic Chemicals

/in Toxic Chemicals/by Industrial DegreasersNumerous industrial companies require the use of certain types of chemicals in order to clean parts, metals, and materials, so that those pieces can be utilized to perform as intended. Industrial companies rely on chemical cleaning agents for their business to thrive, because products that have not been properly cleaned can lead to serious problems, including operation malfunction, lower than expected functionality, and loss of business. In the past, because of the inherent need to clean parts and materials, people who are responsible for implementing the cleaning protocol were exposing themselves to toxic chemicals, whether knowingly and not taking the matter seriously, or unknowingly due to ignorance of the severity of these toxic chemicals. Fortunately, nowadays there is a stringent focus on not only reducing, but also eliminating the potential of harm caused from the exposure to toxic chemicals.

Reducing worker exposure to toxic chemicals is an important matter to all federal regulatory committees. The key is to expose the harmful effects of certain chemical compounds, and alert companies using these chemicals that their business must find alternative sources of chemicals for cleansing materials. Unfortunately, some of these businesses can be stubborn, and will either delay or refuse the transition to another cleaning agent because they have become so accustomed to the one their company has been using, likely for years with consistent success. No matter how much success a company has had with their particular cleaning agent, there is no excuse to allowing workers to endanger themselves by handling toxic chemicals. It is important to explain to these business that, first, it is illegal to ignore the mandates set forth by regulatory committees regarding the stoppage of any use of cleaning chemicals deemed toxic.

The next step is to explain to these businesses that remarkable strides have been made in creating chemical cleaners that are not hazardous to the health of those who come into contact with them, and can clean as efficiently and effectively as traditional cleaners. Companies exist, such as Ecolink, that have performed countless hours of research and development that have led to the solutions that reduce worker exposure to toxic chemicals. Ecolink has identified cleaning agents that can clean as efficiently, if not more efficiently than conventional cleaners made up of toxic chemicals.

It is recommended that, if you are a part of an industrial business that needs cleaning solutions for your parts, metals, and materials, that you contact Ecolink so one of their professionals can help you make the transition to a safer chemical solution that cleans as effectively as the agent currently used by your company. Make the change, and become a part of the movement that many companies have joined that reduces worker exposure to toxic chemicals. In doing so, you not only will be protecting your workers and the environment, but you will likely even save money – view our product list today.