n-Propyl Bromide (nPB) also known as 1-Bromopropane or (1-BP), CAS # 106-94-5 is a brominated hydrocarbon solvent used in a variety of industrial applications, e.g. hand wipe, vapor degreasing, Ultrasonic cleaning, non-destructive inspection and aerosol dispensers commonly consumed for cleaning and degreasing among Aerospace, Electronics, Metal Working, Precision Optics, Asphalt Extraction (Bituminous Asphalt) and to clean and remove microbial contaminants from medical devices and instruments, orthopedic implants, treatment of needles and canola lubricant carrier fluid as well as critical cleaning of oxygen and gas lines.

The use of nPB solvent significantly increased when halogenated solvents such as 1,1,1 Trichloroethane (TCA) ad Tetrachloroethene (PCE) were banned in the early 1990s. Fast forward, 20 + years later, and nPB solvent has undergone considerable health and safety analysis on the potential harm to the reproductive and nervous systems. It can enter your body when you breathe its vapors or drops of spray in the air or can enter your body through your skin.

Further studies by the National Toxicology Program (NTP) and Environmental Protection Agency (EPA) have explored damage to the liver and potential carcinogenicity or cancer. in early 2012, the American Conference on Governmental Industrial Hygienists (ACGIH) released a notice of intended Change to reclassify 1-BP or nPB as a “Confirmed Animal Carcinogen With Unknown Relevance to Humans” and to lower the threshold limit value time-weighted-average (TLV-TWA) from 10 PPM to 0.1 PPM.

More recently during March 21-22, 2013, NTP health scientist Diane Spencer walked the panel through the science of 1-bromopropane, which is a solvent used as a cleaner to degrease electronics and metals,. The panel agreed that the chemical is significant to public health.

Because there were no human studies to consider, Spencer presented the animal data showing the substance caused skin tumors in male rats, large intestine tumors in male and female rats, and lung tumors in female mice. Reviewer Terry Gordon, Ph.D., of the New York University Langone Medical Center, agreed with the data presented, saying he felt the rodent data were biologically relevant to humans, but remained puzzled by the different gender effects.

Although there was little mechanistic data available, the panel generally agreed with NTP conclusions on the genotoxicity data. They felt the overall evaluation was an effective synthesis of integrating the metabolic, genotoxic, and mechanistic data with the carcinogenicity results. The panel also discussed the role that immunosuppression may play in tumor development in animals. “Immunosuppression needs to be mentioned and emphasized more in the document,” said Paul White, Ph.D., of Health Canada, with concurrence from MaryJane Selgrade, Ph.D., of ICF International.

The panel unanimously voted to list 1-bromopropane as reasonably anticipated to be a human carcinogen, based on the animal studies presented by NTP.

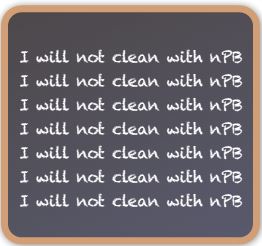

Numerous nPB suppliers “still” promote nPB as an ideal drop-in replacement for chlorinated solvents: Trichloroethylene (TCE) and Perchloroethylene (PERC) which is the equivalent of comparing music cassettes as a drop-in replacement to 8-Tracks and Vinyl Record.

Do you need to upgrade to CD or MP3?

Call the Ecolink team at 800-563-1305 or email to explore safer alternatives for removing nPB solvent hazards from your work environment before its too late. Current exposure limits are 10 PPM (parts per million) with 0.1 PPM proposed by the American Conference of Governmental Industrial Hygienists.

While many of the replacement technologies cost more per gallon or pound, the lifecycle cost is significantly less expensive and MUCH safer [chemical cost + performance + energy + regulations + regulations & exposure limits + toxicity + environmental impact + disposal costs + impact on property and casualty insurance + process time].

Who can put a price tag on workers’ health and safety?

n Propyl Bromide Solvent Information

/in N-Propyl Bromide/by Industrial DegreasersHow to Reduce Exposure to CAS 106-94-5 n-PB, 1-Bromopropane

Solvent Substitution – Using Safer Alternatives

Using Less n-Propyl Bromide

Whether solvent or aqueous cleaning, using less is smart business and keeps your workers o ut of harms way. Keeping containers and equipment (lid on vapor degreasing unit) closed between uses and converting to pre-saturated wipes from nPB solvent soaked rags and keeping rags or pre-sat wipes sealed in an airtightcontainer. For aerosol applications, you may encounter CRC® or LPS®. We offer lots of custom options including bigger can size, more useable content (less propellant) blends. You can even name the product if you’d like!

ut of harms way. Keeping containers and equipment (lid on vapor degreasing unit) closed between uses and converting to pre-saturated wipes from nPB solvent soaked rags and keeping rags or pre-sat wipes sealed in an airtightcontainer. For aerosol applications, you may encounter CRC® or LPS®. We offer lots of custom options including bigger can size, more useable content (less propellant) blends. You can even name the product if you’d like!

Personal Protection – Ventilation, Respiratory and Skin Protection

Local exhaust ventilation is most effective to capture contaminated air at the source before nPB solvent can spread into your breathing zone. Next best is general ventilation or a

solvent can spread into your breathing zone. Next best is general ventilation or a  fan-powered system to bring fresh air into work area as open doors and windows provide very little ventilation. A

fan-powered system to bring fresh air into work area as open doors and windows provide very little ventilation. A half face respirator with organic vapor cartridge and/or mist pre-filter cartridges are recommended, NOT dust

half face respirator with organic vapor cartridge and/or mist pre-filter cartridges are recommended, NOT dust  masks. Wear chemical protective clothing such as gloves, aprons and protective gloves for skin protection.

masks. Wear chemical protective clothing such as gloves, aprons and protective gloves for skin protection.

NPB Solvent Hazard Information

/in N-Propyl Bromide/by Industrial Degreasersn-Propyl Bromide (nPB) also known as 1-Bromopropane or (1-BP), CAS # 106-94-5 is a brominated hydrocarbon solvent used in a variety of industrial applications, e.g. hand wipe, vapor degreasing, Ultrasonic cleaning, non-destructive inspection and aerosol dispensers commonly consumed for cleaning and degreasing among Aerospace, Electronics, Metal Working, Precision Optics, Asphalt Extraction (Bituminous Asphalt) and to clean and remove microbial contaminants from medical devices and instruments, orthopedic implants, treatment of needles and canola lubricant carrier fluid as well as critical cleaning of oxygen and gas lines.

The use of nPB solvent significantly increased when halogenated solvents such as 1,1,1 Trichloroethane (TCA) ad Tetrachloroethene (PCE) were banned in the early 1990s. Fast forward, 20 + years later, and nPB solvent has undergone considerable health and safety analysis on the potential harm to the reproductive and nervous systems. It can enter your body when you breathe its vapors or drops of spray in the air or can enter your body through your skin.

Further studies by the National Toxicology Program (NTP) and Environmental Protection Agency (EPA) have explored damage to the liver and potential carcinogenicity or cancer. in early 2012, the American Conference on Governmental Industrial Hygienists (ACGIH) released a notice of intended Change to reclassify 1-BP or nPB as a “Confirmed Animal Carcinogen With Unknown Relevance to Humans” and to lower the threshold limit value time-weighted-average (TLV-TWA) from 10 PPM to 0.1 PPM.

More recently during March 21-22, 2013, NTP health scientist Diane Spencer walked the panel through the science of 1-bromopropane, which is a solvent used as a cleaner to degrease electronics and metals,. The panel agreed that the chemical is significant to public health.

Because there were no human studies to consider, Spencer presented the animal data showing the substance caused skin tumors in male rats, large intestine tumors in male and female rats, and lung tumors in female mice. Reviewer Terry Gordon, Ph.D., of the New York University Langone Medical Center, agreed with the data presented, saying he felt the rodent data were biologically relevant to humans, but remained puzzled by the different gender effects.

Although there was little mechanistic data available, the panel generally agreed with NTP conclusions on the genotoxicity data. They felt the overall evaluation was an effective synthesis of integrating the metabolic, genotoxic, and mechanistic data with the carcinogenicity results. The panel also discussed the role that immunosuppression may play in tumor development in animals. “Immunosuppression needs to be mentioned and emphasized more in the document,” said Paul White, Ph.D., of Health Canada, with concurrence from MaryJane Selgrade, Ph.D., of ICF International.

The panel unanimously voted to list 1-bromopropane as reasonably anticipated to be a human carcinogen, based on the animal studies presented by NTP.

Numerous nPB suppliers “still” promote nPB as an ideal drop-in replacement for chlorinated solvents: Trichloroethylene (TCE) and Perchloroethylene (PERC) which is the equivalent of comparing music cassettes as a drop-in replacement to 8-Tracks and Vinyl Record.

Do you need to upgrade to CD or MP3?

Call the Ecolink team at 800-563-1305 or email to explore safer alternatives for removing nPB solvent hazards from your work environment before its too late. Current exposure limits are 10 PPM (parts per million) with 0.1 PPM proposed by the American Conference of Governmental Industrial Hygienists.

While many of the replacement technologies cost more per gallon or pound, the lifecycle cost is significantly less expensive and MUCH safer [chemical cost + performance + energy + regulations + regulations & exposure limits + toxicity + environmental impact + disposal costs + impact on property and casualty insurance + process time].

Who can put a price tag on workers’ health and safety?

n-Propyl Bromide Replacement

/in N-Propyl Bromide/by Industrial Degreasersn-Propyl Bromide Exposure Risks

In March 2013, National Toxicology Program (NTP) and a panel of experts unanimously voted to list 1-bromopropane, also known as nPB, CAS # 106-94-5, as a “reasonably anticipated to be a human carcinogen,” based on the animal studies presented by NTP to include as part of their 13th Report on Carcinogens (RoC). This coincides with a study by US Department of Defense to lower TLV-TWA to 0.1 PPM.

as nPB, CAS # 106-94-5, as a “reasonably anticipated to be a human carcinogen,” based on the animal studies presented by NTP to include as part of their 13th Report on Carcinogens (RoC). This coincides with a study by US Department of Defense to lower TLV-TWA to 0.1 PPM.

Vapor Degreasing

For almost 20 years, nPB served as a drop-in replacement for chlorinated solvents such as TCE and PERC to remove adhesives, greases, hydraulic fluids, metalworking fluids, oils, sealants and waxes in vapor degreasing operations. Enviro Tech, Petroferm and Solvon are primary suppliers for bulk cleaning.

Currently, fluorinated blends (HFC, HFE and HFPO) offer much higher & safer work exposure limits (200 PPM versus 0.1 PPM) and added benefits of reduced material handling (i.e. stabilizing, acid acceptance testing and dumping/recharging solvent), energy reduction (almost 40%, 43C vs 71C), superior cleaning performance at a lower lifecycle cost of ownership.

Email or call 888-996-8436 ext 125.

Aerosol Applications

nPB is readily used and packaged in aerosol cans for the effective removal of grease, oil, corrosion and sludge from gears, bearings, motors and contact cleaning where sensitive plastics are not involved. CRC® and LPS® are two primary aerosol providers of various blends with nPB. If you are using No Flash, Electra X or Electronic Degreaser, Super Degreaser it is time to switch and reduce your worker’s exposure to nPB.

Ecolink offers multiple custom blends that are safer, cost-effective and perform. Email or call 888-996-8436 ext 125.

Replacement by the Numbers

For vapor degreasing applications, the acquisition cost of nPB at $4-6/lb. compared to fluorinated options at $9-12/lb. is not the way to calculate replacement costs. Solvent bath life and process time (up time) will more than offset acquisition cost variance with most conversions generating positive ROI and cash flow in less than 12 months. For aerosol applications, cost $/can is flat. Fair market value:

Degreasing = $12-22/can

Defluxing = $9-18/can

Contact cleaning = $15-25/can

AK-225 Replacement Options

/in AK225/by Industrial DegreasersIn order to continue to operate with nonflammable solvents for your degreasing applications you have limited choices. Methylene Chloride, TCE and PERC have documented health hazards and banned in multiple parts of world and US. nPB, n-propyl bromide hazard alert has proposed 0.1 PPM exposure limit leaving wildly expensive HFC’s, HFE’s and HFPO’s.

Primary suppliers include: Chemtronics®, CRC®, LPS®, MicroCare®, Miller Stephenson, and TECHSPRAY® and now Ecolink offers a complete line of bulk and aerosol options custom made specific to your environment.

Degreasing

The AK-225 phase-out has many industrial consumers navigating expensive cost-benefit trade-offs on replacement options. One of the primary applications of AK-2225, precision degreasing of metals, typically involves vapor degreasing equipment (ex: Baron Blakeslee, Branson) and aerosols. Call 888-996-8436 ext 125 or email to explore custom blends specific to your budget, regulatory compliance requirements.

Fair market value: Bulk = $120-180/gal or $10.50-13.25/lb, Aerosol = $12-22/can

Defluxing

Removing R, RMA, RA Rosin-based flux, no-clean and lead free flux often involves high value parts and people. In bulk and aerosol settings, balancing defluxing performance with worker’s health and safety leaves little margin for error. There are multiple hot and cold ways of defluxing in equipment or soak tanks and countless aerosol options. So where do you get best bang for $?

Fair market value: Bulk = $110-150/gal or $9.40 – 12.35/lb, Aerosol = $9-18/can

Contact Cleaning Aerosols

Rapid evaporation. No volatile residue (NVR). Plastic Compatible. No ODC (ozone depleting chemicals). Sound familiar? Most of the tried and true blends on the market are slightly different versions of the same recipe. All of them remove oxides, oil, grease and dust from electrical contacts, relays, encoders, slide wires, rheostats, distribution panels and switching devices.

Fair market value: Aerosol = $15-25/can

The tricky part with choosing among aerosol suppliers is two-fold:

1) Size of can, # of ounces. Simply put, filling more ounces requires fewer cans.

2) Propellant as % of total fill. This is difficult to catch as there are LOTS of fancy words and CAS #‘s that are impossible to pronounce or determine if it actually cleans.

Bottom line: do not get fooled on price per can. Not sure how to determine if you are paying more than fair market value? Call 888-996-8436 ext 125 or email.

AK-225 Replacement Options

/in AK225/by Industrial DegreasersNot for much longer. Depending on who you ask in the industry and US government regulatory agencies the official mandated phase-out date is December 31, 2014 for HCFC-225 commonly known as Asahiklin AK-225 for precision cleaning, 225AES, 225T and 225ATE for defluxing, drying where alcohol azeotropes are used, 225DH for displacement drying and 225G for oxygen cleaning. Several notable sources are exiting the market by mid-year as early as June 2014. This material is manufactured in Japan and requires at least three months scheduling to allow for ocean shipping. Time’s up! Need help sourcing an alternative? Please call 888-996-8436 ext 125 or email to explore ready-to-ship and sell off-the-shelf solutions or work with our technical team to design custom blend specific to your success criteria in bulk and aerosol packaging.

AK225 Phase-out 12/31/14

Vapor Degreasing

Aerosol Applications