What is Deionized Water?

Deionized water, also known as DI water or demineralized water, simply means water that has had ions removed. Ions are electrically charged molecules found in sunlight, radiation, air, and water. They either have a net positive or net negative charge: ions with a positive charge are “cations” and negatively charged ions are “anions.”

For industrial, chemical, and other applications in which water is used as a rinsing agent, these ions are considered impurities and need to be removed from the water for accurate work. Some common ions found in water include:

- Calcium (Ca++)

- Iron (Fe+++)

- Sodium (Na+)

- Hydrogen (H+)

- Chlorides (Cl-)

- Hydroxyl (OH-)

- Sulfates (SO4–)

- Nitrates (NO3-)

How is Deionized Water Made?

DI water is made by running any type of water (tap, distilled, spring, etc.) through a resin that is electrically charged; both positive and negative ions are in this resin. Sometimes, two electrically charged resins may be used–one resin will remove the negatively charged ions, and one will remove the positively charged ions. The cation resin, or the one containing positively charged ions, is usually first in line.

When the starting water is rinsed through the resin(s), the cations and anions exchange with hydrogen (H+) and hydroxyl (OH-) in the resin, which in turn produces H2O or water. This process results in demineralized water, which is reactive, meaning that the properties of the water begin to alter as soon as it is exposed to air. Normal water has a pH of about 7, which is neutral on the pH scale. DI water also has a pH of 7 after initial production, but the carbon dioxide in air incites a reaction that produces hydrogen and bicarbonate (HCO3-), lowering the pH to about 5.6, which is more acidic than normal water.

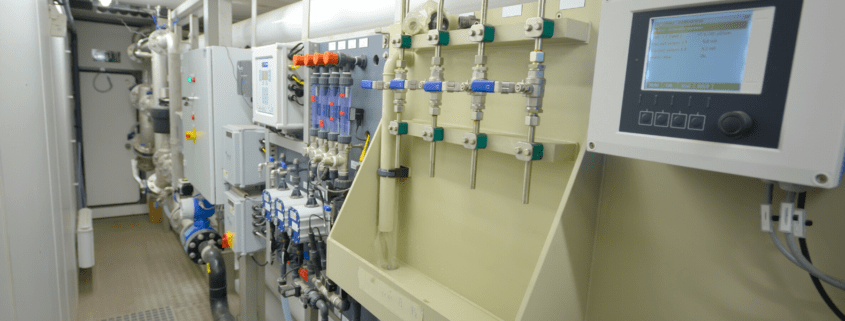

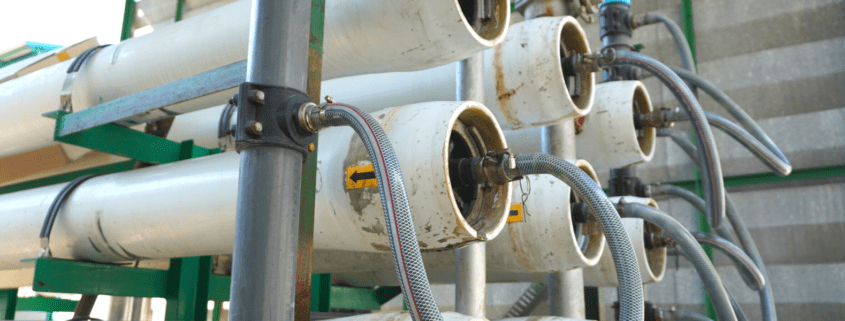

Demineralized water is made in something called a DI water system. This system is an arrangement of water tanks (and other components) that are used to purify water. A DI system can be a single tank or a set of multiple tanks and may be used for other water purification methods such as UV disinfection or reverse osmosis. Each tank in these systems contains the electrically charged resin used to remove ions from water. Tanks may be larger or smaller in size, depending on the quantity of water that will be processed through them.

What is Deionized Water Used For?

Usually, DI water is used in chemical laboratory settings where the water needs to be 100% pure. Higher water purity means more predictable, accurate results that can be repeated multiple times. This is also useful in pharmaceutical settings.

Aside from this, demineralized water has several household applications. This includes:

- humidifiers

- household appliances that produce steam

- aquariums

- automotive car

- cleaning products

- hygiene products

- fragrances

Need to Make Some Deionized Water?

Look no further! Contact the Ecolink team with any questions you may have. We provide a whole product category of water treatment chemicals to find the one that best fits your needs!