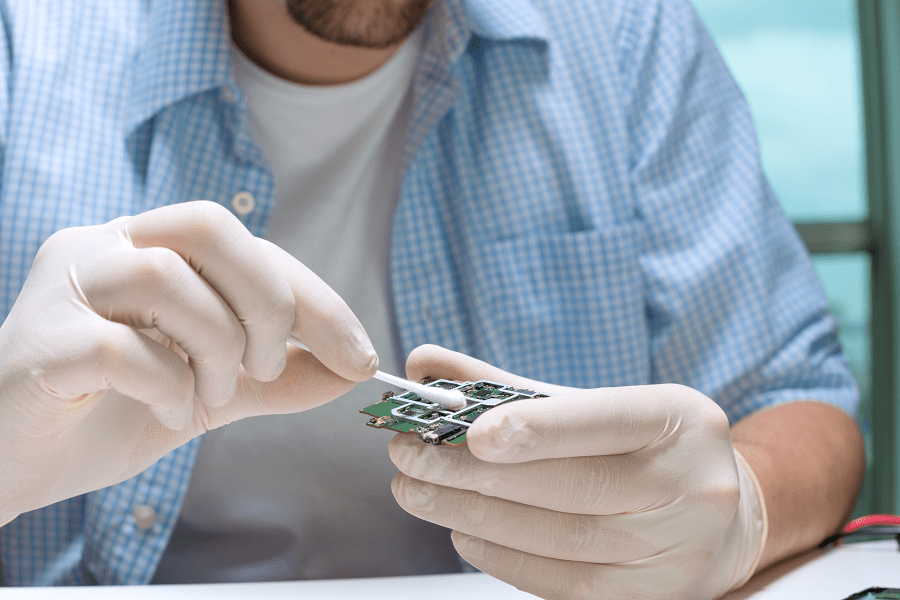

Sold on the industrial, commercial, and residential markets, isopropyl alcohol (IPA) cleaner has a wide variety of uses, from killing germs, to cleaning general surfaces, to cleaning electronic components that play a critical role in business operations. Ecolink...