Coil Rewinding & Industrial Solvents

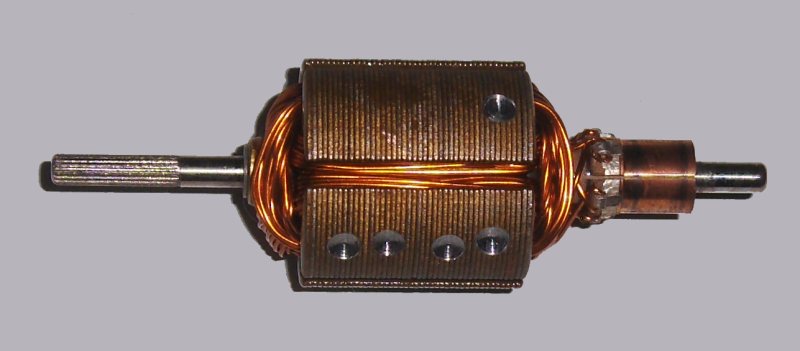

Companies in the armature rewinding-business re-wind damaged coils or stators, fix hermetic seals on electric motors, and generally restore electric motors and components. In order to fix everything from small automotive generators to giant industrial and utility devices, industrial solvents are consumed in massive quantities annually by more than 2,300 companies, mostly small service centers. A mistake or poorly performed rewind job will result in a motor that does not work.

Top 4 Mistakes to Avoid with Industrial Solvents Used for Armature Rewinding

- Dielectric strength – the higher the better. Problem: not enough can create potential for arcing. Solution – make sure you check with the chemical manufacturer for the voltage rating of the industrial solvent — at least 40,000 volts and tested per ASTM D-877 test procedures

- Dry time – time is money, save both. Problem: too often slower drying chemicals are used which extend equipment down time and also extend maintenance schedules. Solution: follow clean cycle with a chemical rinse or dry cycle. NPB-based solvents work very well for improving dry time with an added benefit of removing any excess cleaner that may contain volatile residue

- SARA or RCRA listed ingredients. Problem – cost more money for handling and disposal. Solution – read the label and avoid any industrial solvent containing SARA or RCRA listed ingredients. There are lots of choices

- Flammability – below 140°F. Problem: fire hazard liability + costs more money for inbound freight and outbound disposalSolution: always purchase non-flammable industrial solvents. There are lots of choices

Take your Pick: Electron or Positron to clean + Hypersolve™ to rinse or dry for Armature rewinding, AC generator rewinding, Servo rewinding, Traction rewinding, Hermetic rewinding & Transformer rewinding

Electron: 46,000 volt dielectric strength, 147°F flash point, NO SARA or RCRA listed ingredients, Siemens & GE approved since 1991

Positron: 48,000 volt dielectric strength, 142°F flash point, NO SARA or RCRA listed ingredients, Siemens & GE approved since 1991

Hypersolve™: similar physical properties and cleaning efficacy to 1,1,1-Trichloroethane (TCA), No flash point exhibited by standard ASTM procedures, quickest dry-to-dry cycle. In use by several USBR and USACE Dams for overhaul of large hydroelectric generators throughout U.S.

Special Offer for Armature Rewinding Shops

Ecolink Inc. is offering a 15% discount and FREE shipping for any new cleaner degreasers, degreaser chemicals, or industrial solvent manufactured or distributed by Ecolink Inc.

We offer numerous alternatives to:

|

|

|

|

|

|

|

Call 800 563-1305 or email info@ecolink.com to discuss your current use of any of these or other manufacturer’s brand to switch and start saving. With over 200 industrial solvents to choose from, including several new formulations not yet listed on the website, we feel certain we can expand upon the savings and safety improvements enjoyed for nearly 20 years. Chemist owned and operated, we offer guaranteed FREE samples, including FREE freight, to evaluate for a RISK-FREE evaluation.

Compatible Electric Motor Manufacturers (partial list)

- Baldor Electric Motors

- Fincor Electric Motors

- Leeson Electric Motors

- Marathon Electric Motors

- Weg Electric Motors