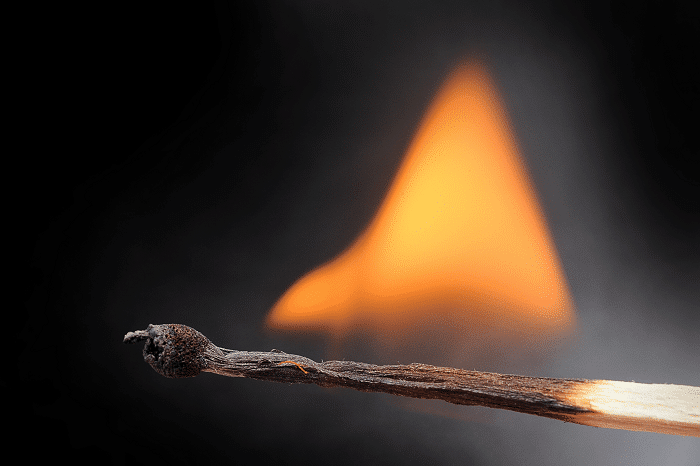

The flash point of a solvent is the temperature at which it ignites. More specifically, it is the temperature at which vapors from the solvent ignite. This is why an ignited solvent appears to burn only on the surface and not throughout its entire constitution when it is stored in large volume in a vat. A solvent that behaves this way often has a low flash point. Replacing it with a high flash point solvent can deliver the following crucial advantages, among others.

- Broader Range of Application

The proper use of low flash point solvents is limited to tasks that don’t involve catalysts that could cause the solvents to combust. Because high flash point solvents ignite less easily than low flash point solvents, the former naturally have a broader range of application. However, it’s important to remember that high flash point solvents can still ignite. Before you use them for a specific application, be sure that the work process would not cause them to combust.

- Reduced Chance of Injury

In terms of worker safety, the greatest risk of solvents that have a flash point is burn injuries. The lower the flash point of a solvent, the greater the risk of injury when the cleaner is used in certain capacities. Solvent-related burn injuries can cause workers to take extended time off and result in chemical injury lawsuits. By protecting their workers against burn injuries, companies and organizations also protect themselves against negative financial situations.

- Reduced Cost of Protection

Anyone who works with solvents that have a flash point should wear personal protective equipment (PPE) to prevent burn injuries. However, the level of PPE that should be used — and thus the cost of acquiring it — is based on the magnitude of risk that using the solvents entails. Using high flash point solvents may not eliminate the need for PPE, but it may allow you to outfit workers in a lower level of PPE than would be needed if high flash point solvents were used.

- Simplified Solvent Storage

Low flash point solvents should ideally be stored in an area that is free of ignition sources that could combust them and free of combustibles that could feed the fire if ignition occurred. High flash point solvents also entail fire-related storage considerations, but they are naturally safer to store in the presence of ignition sources and combustibles than their low flash point counterparts. Using solvents that have a high flash point can simplify solvent storage.

Need High Flash Point Solvents?

If so, you have arrived at the right destination. Ecolink supplies environmentally preferred and environmentally safe cleaning solvents whose flash points range from relatively low to exceptionally high. We also supply solutions that have no flashpoint and are essentially inflammable. Replacing low flash point solvents with solvents that have a high flash point brings the crucial advantages above, which support productivity and stable operating costs.