US Bureau of Reclamation: Electron Solvent & Hypersolve™

If you are bidding on any USBR dam projects that specify the use of Electron solvent or denatured alcohol for wiping the rotor of a large hydroelectric generator, please call 800 886-8240 or email info@ecolink.com.

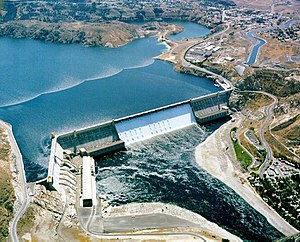

Image via Wikipedia

Electron solvent is approaching its 20th anniversary and was originally approved by Siemens-Westinghouse and General Electric for their turbines and generators. We offer denatured alcohol in convenient 5-gal pail container size along with many other commodity chemicals used during the maintenance, repair, and overhaul of hydroelectric generators. However, if you prefer a non-flammable alternative with much more solvency than denatured alcohol or comparable industrial cleaners than we urge you to upgrade to Hypersolve™ as a safe, effective, and best-in-class npb solvent. When paired with Electron it delivers a 1-2 punch that knocks out even the most baked on, caked on dirt and soils.

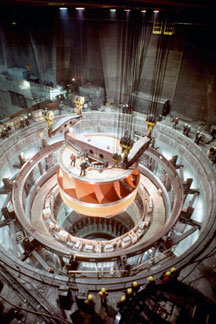

Electron & Hypersolve™ helped maintain Grand Coulee Dam during Major Overhaul

After more than 10 years of cleaning critical components with Electron at Grand Coulee Dam, the engineers and electrical technicians were seeking a safer and more effective alternative to denatured alcohol. After a series of site visits and product compatibility testing, Hypersolve™ was approved and has been in use for over 3 years.

10 years of cleaning critical components with Electron at Grand Coulee Dam, the engineers and electrical technicians were seeking a safer and more effective alternative to denatured alcohol. After a series of site visits and product compatibility testing, Hypersolve™ was approved and has been in use for over 3 years.

As recently as August 2009, Electron and Hypersolve™ played a significant role as part of a $2M multi-year contract for Grand Coulee Dam Third Powerplant Unit Overhaul. The six generating units in the Third Power Plant (TPP) have been in service since the mid-1970s. Age-related wear began to create problems, which resulted in increased power outages and reduced reliability.

The overhaul project will ensure continued operation of the power plant and provide a reliable source of hydroelectric power to the region. These efforts, along with Electron and Hypersolve™, will result in improved reliability of equipment; minimizing outage durations, and will reduce the likelihood and magnitude of increases to outage time.

Special Offer for USBR Dam Employees

Ecolink Inc. is offering a 15% discount and FREE shipping for any new cleaner degreasers, degreaser chemicals or industrial solvent manufactured or distributed by Ecolink Inc.

We offer numerous alternatives to:

|

|

|

|

|

|

|

Call 800 886-8240 or email info@ecolink.com to discuss your current use of any of these or other manufacturer’s brand to switch and start saving. With over 200 products to choose from, including several new formulations not yet listed on the website, we feel certain we can expand upon the savings and safety improvements enjoyed for nearly 20 years. Chemist owned and operated, we offer guaranteed FREE samples, including FREE freight, to evaluate for a RISK-FREE evaluation.

Grand Coulee Dam Statistics

Source: Wikipedia.org

- Largest concrete dam and concrete structure in North America with 11,975,521 yd³ (9,155,942 m³) used[24]

- Total length of dam: 5,223 ft (1,592 m)

- Length of main dam: 3,867 ft (1,178 m)

- Length of forebay dam: 1,170 ft (356 m)

- Length of Wing Dam: 186 ft (56 m)

- Hydraulic height: 380 ft (116 m)

- Height of dam from bedrock: 550 ft (168 m)

- Height above original streambed: 401 ft (122 m)

- Reservoir Lake Roosevelt stretches for 151 mi (243 km)

- Average release: 110,000 ft³/s (3,100 m³/s)

- 4 power plants, 33 generators

- Installed generating nameplate capacity: 6809 MW [24]

- Annual energy production: 25 TWh in 2007[25] (varies with annual river flow)

- Capacity factor: 41.9% in 2007

- In 2007, Grand Coulee generated the second-most energy among US power facilities, after the Palo Verde Nuclear Power Plant at 26.78 TWh.[25] Palo Verde has a lower nameplate capacity but operates at a higher capacity factor, giving it slightly more annual output.