Spray cleaner for electronic equipment is used to remove dirt and grime that accrete on electronic components over time. However, within this broad classification of spray cleaner exists several types of products, not all of which are appropriate for all types of electronic component cleaning operations. That is why it’s essential to consider the four factors below before your organization places an order for a new spray cleaner for electronic equipment.

- Spray Method

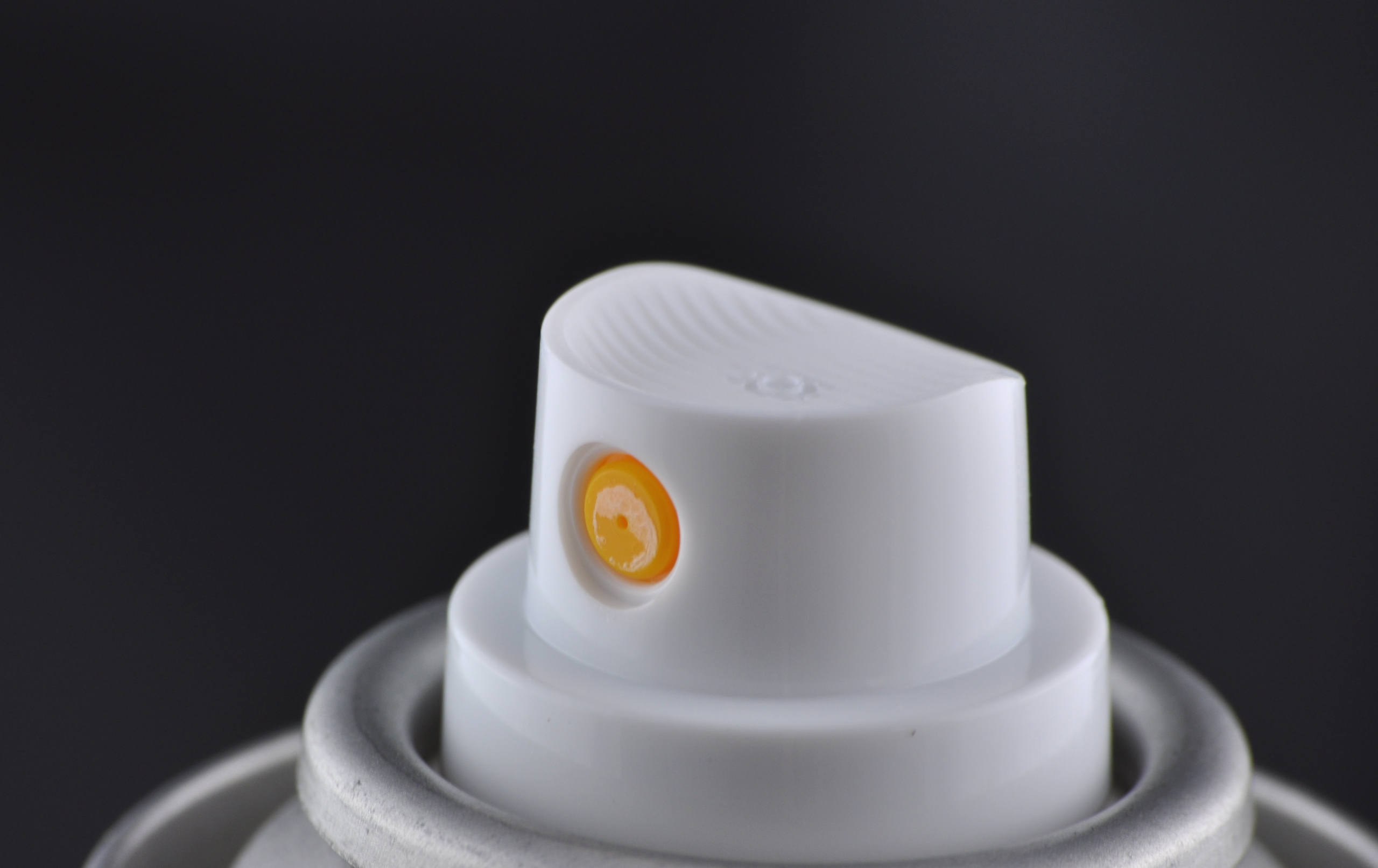

Spray cleaner for electronic equipment is typically applied using one of the following methods of dispersal: aerosol dispersal, pump action spray bottle dispersal, and electronic spray equipment dispersal (e.g., power washers and spray cabinets). Each method has its own unique benefits.

The first method is an excellent choice for cleaning precision parts that require minimal spray. The second method is a good option for cleaning precision parts that require a more significant volume of spray. The third method is a fine choice for uniformly applying spray to multiple parts simultaneously (e.g. spray cabinets) or cleaning tough equipment housing (e.g., power washer).

- Cleaner Residue

Because the goal is to clean the equipment thoroughly in order to keep it soil-free as long as possible, you should ideally choose a spray cleaner for electronic equipment that is residue-free. In addition to potentially causing current transmission problems for electrical contacts, residual cleaner can also have the undesirable effect of attracting dirt and grime. Over time, this phenomenon can lead to a vicious cycle of applying more and more residual cleaner.

- Dielectric Formulation

A dielectric spray cleaner for electronic equipment contains a dielectric formulation that serves as an insulator between the spray nozzle and the electronic equipment that is sprayed clean. Consequently, choosing a dielectric spray cleaner is especially important for cleaning energized equipment such as engines and switchgear. Dielectric spray helps prevent, explosions, fires, and serious injuries that can result from using liquid cleaners that lack an electrical buffer.

- Material Cleaned

It’s also essential to choose a spray cleaner for electronic equipment based on the material that must be cleaned. For example, if you need an electrical contact cleaner, be sure to choose one whose ingredients will not corrode the metal from which contacts are made. If cleaning rubber wire sheaths and harnesses is necessary, make the same consideration for these components.

Need a New Spray Cleaner for Electronics?

If so, you have come to the right place. Ecolink has a rich history of supplying companies and organizations with best in class, industrial spray cleaners that are suitable for cleaning various types of electrical equipment. As you browse through our products, there is a good chance that will find exactly what you require. If not, simply share your cleaning requirements with us, and we will formulate a custom spray cleaner for electronic equipment that meets all of your needs.

For help choosing the best solution for your equipment cleaning needs, call us today at (800) 563-1305, or fill out the contact form on our website. We look forward to hearing from you!