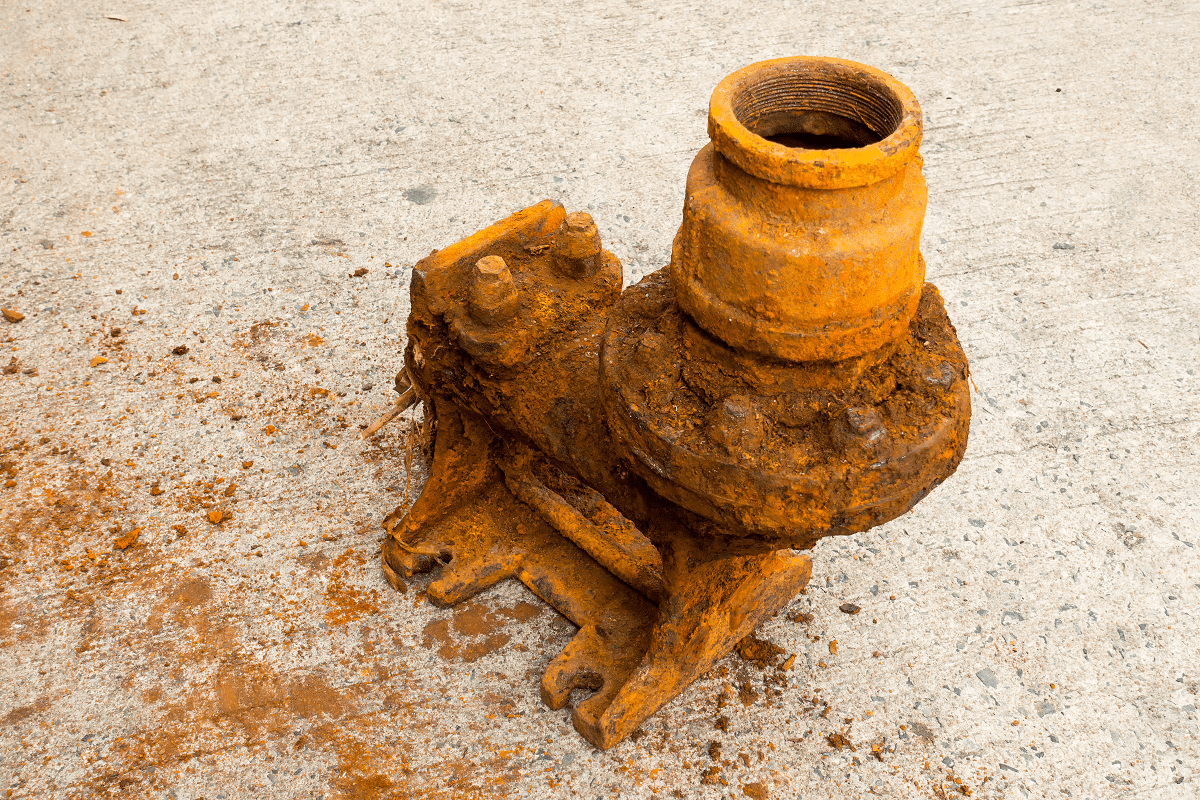

Rust is a common sight on industrial equipment and parts, but it doesn’t have to be. Just because metal rusts doesn’t mean it has weak dimensional stability. However, if rusting progresses unchecked, it will eventually devour the metal it affects, literally turning it into a pile of rust over the course of months or years.

Companies and organizations can prevent rust by applying Rust Rip rust remover and phosphatizer to surface accumulations of rust before they progress deep into the metal. Rust Rip is one of the best rust removing solvents for industrial users. Below are four reasons why.

- Compatible With Ferrous / Non-Ferrous Metals

Some industrial rust removing solvents are formulated for ferrous metals, others are created for non-ferrous metals, and still others are designed to remove rust from both types of metal. Rust Rip belongs in the third category of industrial rust removing solvents; it removes rust from ferrous and non-ferrous metals equally well, with no unexpected surprises in store.

- Non-Flammable

Non-flammability is always considered a positive trait of an industrial solvent. But the true value of a non-flammable formulation depends on the work environment where the solvent is applied. If you need to apply or store rust removing solvents in areas that have sources of ignition, Rust Rip lets you do it without jeopardizing the fire safety of workers and the building itself.

- Promotes Paint Bonding

As stated on Rust Rip’s product page, “[Rust Rip] destroys the corrosive agents that support oxidation and leaves a clean, rust-free, metal surface… [creating] minute inert elements that become an integral part of the metal surface, without changing tolerances, and prevent further rusting.”

Known as phosphatizing, this process creates a surface that’s perfect for paint bonding. Coating equipment and parts in paint that thwarts rust development is an excellent rust protection measure — a measure made possible by properly applying Rust Rip.

- Preserves Functionality of Metal

Rust negatively affects practically any characteristic you would desire in metal, including ductility that provides flexibility, hardness that delivers strength, and softness that makes metal easy to form into parts with a machine.

Keeping metal rust-free with Rust Rip makes it easier for metal to retain the properties required to supply it with these metallurgical characteristics and others. Rust has no place in industrial metallurgy. Rust Rip helps ensure that rust stays away.

Place Your Order Today

If you’re shopping for environmentally preferred rust removing solvents that treat ferrous and non-ferrous metals, are non-flammable, promote paint bonding via phosphatization, and help preserve the functionality of metal, Rust Rip is a good match for your needs.

If you have additional requirements that Rust Rip doesn’t address, we can create a custom solvent that is tailored to your needs. To see how one of our solvents works before you order, simply request a free sample — no strings attached.

Place your order for Rust Rip today through our website, call us at 800-563-1305, or send us an email using our contact form. Use Rust Rip to banish rust and prevent further rusting!