Precision parts cleaning sounds like a technical process that has a lot riding on the final result — and it’s true. Simply put, precision parts are components that have the least tolerance for alterations that affect how they are designed and intended to operate.

For example, a precision part that warps is technically no longer a precision part; its dimensions are imprecise compared to the original design. In an operational capacity, a precision part that contains coatings or residues that impact its function no longer operates precisely, either; rather, it operates imprecisely and may even experience accelerated wear.

This is why it’s important to choose a precision medical parts cleaning solution that preserves the “preciseness” of the dimensions, surface quality, and overall operation of the parts you clean. If you’re ready to select a precision medical parts cleaning solvent, below are four crucial considerations that will help you choose the right cleaner for your requirements.

1. Type of Metal

The type of metal you clean determines the type of cleaning agent you use. Chemicals that are considered corrosive to the metal are avoided. Common examples of chemical bases that corrode metal are ammonium hydroxide, potassium hydroxides, and sodium hydroxide. Common examples of corrosive acids are hydrochloric, sulfuric, nitric, chromic, acetic, and hydrofluoric.

2. Cleaning Method

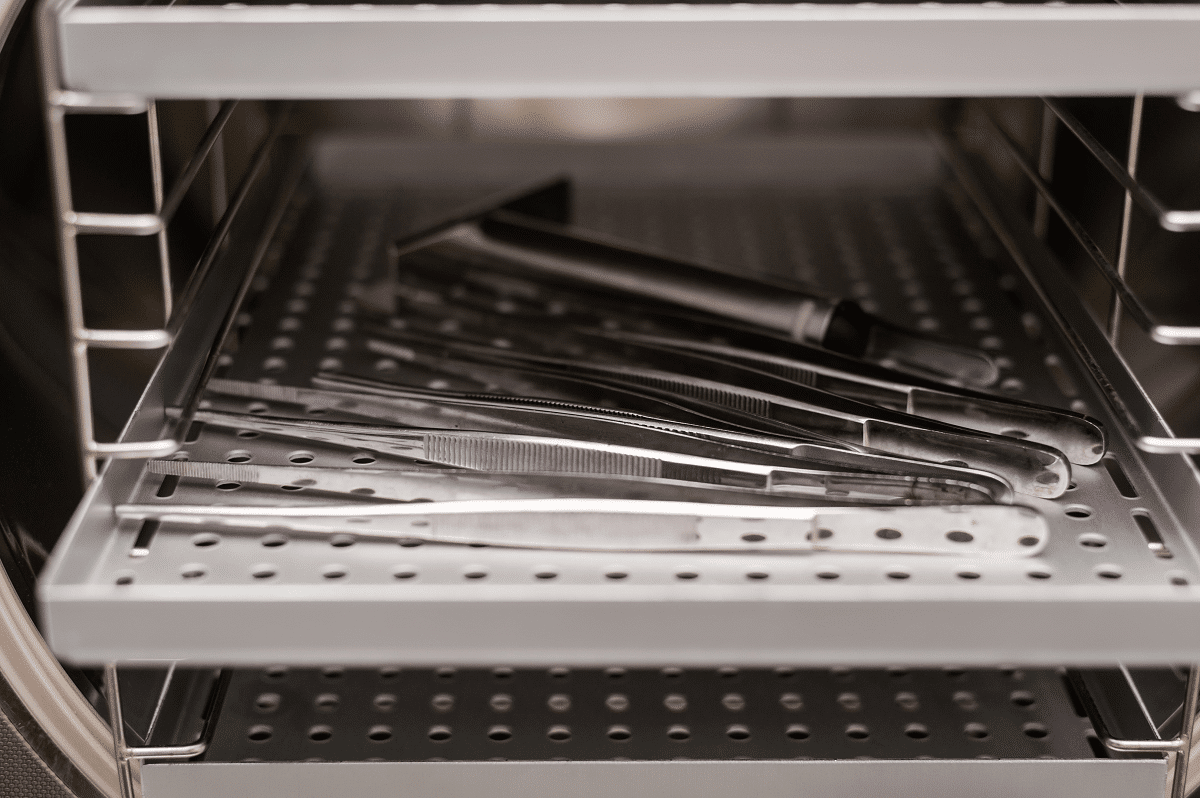

Precision medical parts cleaning is often performed using an enclosed parts washing system. If this is how you clean metal parts, in addition to selecting a solvent that’s safe for the metal, you’ll select a solution that the washing system is designed to accommodate.

If you’ll clean a part that’s too large for a parts washing system, then you’ll look for a solvent application method that dries quickly, leaves no residue, can penetrate crevices via capillary action, and distributes uniformly over the surface of the part. Aerosol is often a good choice for addressing these requirements.

3. Part Application

The degree of precision cleaning required depends partly on the end use of the part. For example, a part that doesn’t touch skin requires a high degree of soil removal, but a part for invasive surgery may require a deeper degree of soil removal. In either case, no soil is visible to the eye, but even microscopic particles could pose a serious danger in the second situation, depending on what they are.

4. Worker Safety

When it comes to precision medical parts cleaning and worker safety, there are two ethical choices: Use solvents that have known health risks and outfit workers and the work environment with equipment that eliminates the risks, or use non-toxic solvents that require minimal protective measures.

When you consider the cost of high-level personal protective equipment (PPE), a special air filtration system, and the cost of maintaining the system, using non-toxic solvents is normally the most economic route.

Contact Us Today

Ecolink specializes in supplying precision parts cleaners that have a good safety profile for humans and the environment. We supply stock solutions and formulate custom solutions to address unique cleaning requirements. What’s more, we’ll provide you with a free solvent sample, so you can see how a solution works before you place an order.

Call us today at 1-800-563-1305, or send us an email using our contact form. We look forward to supporting your precision medical parts cleaning jobs!