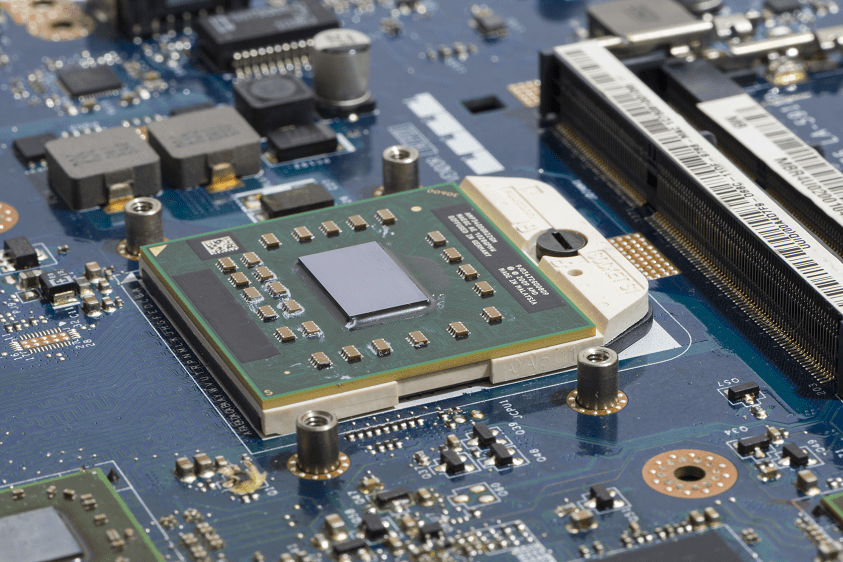

Printed circuit boards (PCBs) are found in all but the simplest electronic devices. Because PCBs featuring embedded or non-embedded components are protected by equipment housing, they seldom experience physical stress that could cause damage, such as warping and cracking.

However, because equipment that contains PCBs frequently contains a ventilation system, PCBs are subject to accumulations of dust, oil particles, or other particulate matter that can pass through the ventilation slots, forming a stable layer of accumulation on the boards.

There are two options for addressing the situation: Eliminate accumulating particulate matter from the environment where PCBs are present, or use PCB cleaning solvents to remove accumulations. Many companies and organizations find the second option more feasible than the first.

Choosing PCB Cleaning Solvents

Because equipment housing — as well as parts inside the housing, in some cases — must be removed to access PCBs, cleaning them can be a pain. However, if they carry accumulations, the electrical conductivity of the boards can suffer. With this in mind, we look at three key performance indicators of PCB cleaning solvents that should be considered before purchase.

- Dielectric Formulation

If you need to clean PCBs while the equipment containing them remains energized, using a solvent with a dielectric formulation is a must. The dielectric in the solvent serves as a buffer that prevents electricity from traveling through the solvent and delivering a strong shock. The more live voltage is involved, the more crucial it becomes to use a dielectric solvent for safety reasons.

- Solvent Residue

Solvent residue can spell doom for the functionality of PCBs, especially if the residue contains a dielectric that impedes transmission of electricity. Even when a dielectric isn’t present, the presence of residue poses a common problem: Particulate matter is attracted to the residue. Consequently, using a solvent that leaves a residue can require PCBs to be cleaned more frequently than if a non-residue solvent were used.

- Compatibility With Materials

Unless PCBs are removed from their devices for individual cleaning, the user needs a PCB cleaning solvent that won’t harm materials that surround the boards, particularly plastic and metal computer components.

PCB cleaning solvents are often used aerosol form to ensure solvent is dispersed uniformly across the cleaning surface. The aerosol will also contact nearby components, and should be selected based on compatibility with the components’ materials.

Need PCB Cleaning Solvents?

If so, Ecolink is a great place to get you need. We offer eco friendly stock solvents that are suited for cleaning PCBs, as well as create custom solvents that are designed for specific users.

Choose the method of solvent dispersal you need (e.g., aerosol, hand wipe, pump spray, etc.) and order your solvent in a small volume, a large volume, or something in-between. Before you order, you also have the option of receiving a free test sample, with no obligation to buy.

To get started on selecting an environmentally preferred PCB cleaner, call us today at 800-563-1305, or send us an email through our contact form. We look forward to assisting you!