The Metal Degreasing Process: Why Use a Parts Washing Machine?

Metal parts and surfaces are some of the most frequently degreased equipment in industrial work environments. From removing light accumulations of motor oil on engine parts to cleaning away greasy accumulations that accrete on grease trap components, the metal degreasing process is one of the most essential cleaning measures for sustaining business productivity.

Using a Parts Washing Machine

To maximize its effectiveness, metal degreasing must be performed using the best parts washing method and the most efficacious degreasing solvent. When it comes to choosing a parts washing method, the best solution may be to use a parts washing machine. If your company or organization’s metal degreasing process involves any of the following factors, there’s a good chance that you could benefit from using a parts washing machine.

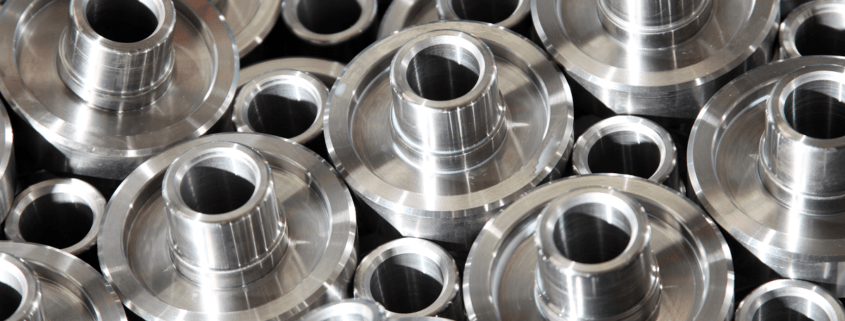

- Cleaning Precision Parts

Due to their highly detailed design that often features complex contours, precision parts can be exceptionally difficult to clean by hand. Because a parts washing system applies cleaning solvent uniformly across the entire surface of a part under heat and pressure, these elements of precision parts typically don’t pose an obstacle to the degreasing process. All you have to do is follow the machine’s instruction manual, and let the equipment do its job.

- Reducing Workplace Emissions

Emissions from cleaning solvents is a common safety concern in industrial work environments for two reasons: the potential violation of emission caps and the potential health threat to workers. Using a parts washing machine instead of an open air degreasing process can help address these issues. When a parts washing machine maintains an airtight seal, it prevents measurable emission levels that could result from the evaporation of the cleaning agent.

- Reducing Solvent Expense

Using a parts washing machine for the metal degreasing process can help you reduce solvent expense in two ways: by preventing solvent from evaporating in open air and recycling solvent by purging it of grease that comes from soiled parts — a process that happens inside the machine and is commonly performed when a vapor degreasing solvent is used. Using a parts washing machine can be an excellent strategy for reducing long-term solvent expense.

- Expediting Parts Cleaning

Industrial grade parts washing machines excel at removing heavy accumulations of grease in a short period of time without compromising the integrity of the parts they clean, especially when a machine that features conveyor processing is used. For many companies and organizations, expediting parts cleaning is the primary reason for implementing a parts washing machine.

Need the Best Metal Degreaser?

Using a parts washing machine for the metal degreasing process offers several advantages, but only when a highly efficacious degreasing solvent is used. If you’re looking to implement an eco friendly metal degreaser that’s a perfect match for the parts you clean and the machine you use to clean them, we can provide you with a stock cleaner or a custom cleaner that meets your unique requirements. Call us today at (800) 563-1305, or use the contact form on our website.