When it comes to commercial and industrial degreasing applications, moisture can be both a benefit and a drawback. Some applications, such as the cleaning of glass of high-grade plastics, can benefit from moisture condensing on the surface of the material to create wetness. However, for metal parts that are sensitive to moisture-induced oxidation, applying a degreaser to remove moisture is typically an essential requirement for the degreasing application.

How Oxidation Occurs

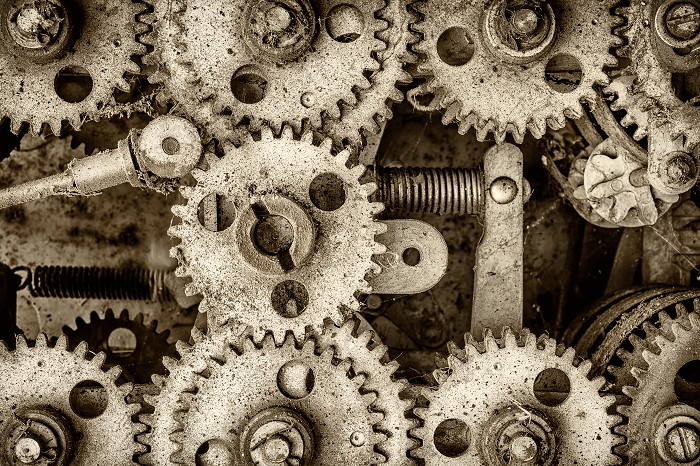

More commonly known as “rust”, oxide can create major problems in mechanical components that go unnoticed until it is too late to repair them economically. This is often because, when moisture is consistently present in the degreaser solution, it invades the tight spaces between components and essentially causes them to oxidize from the inside out. Initially, oxide presents on the surface, but it can affect the internal microstructure of metal if it is left unaddressed.

The stable layer of oxide that forms on the surface can be removed, but doing so is likely to be time consuming and expensive, and often requires the help of a heat treating company that specializes in metal finishing procedures, such as electropolishing. With that said, replacing rusted components is often as cost prohibitive as repairing them. Consequently, the best option is to use a non-moisture degreaser that removes moisture from the degreasing process.

Choosing the Right Product

The type of moisture-free degreaser you need ultimately depends on the application for which you need it. For example, if you need to clean sensitive electrical components with an open air spraying application, selecting a degreaser that has a dielectric formulation would be a smart choice. If you need to clean metal parts using a parts washing system, using a degreaser that has a fast drying, vaporous cleaning action would be a good choice for many alloys, especially ones that have a low degree of the chemical element chromium, and thus oxidize rather easily.

Need Help With Product Selection?

Unless you have experience in choosing a degreaser to remove moisture from cleaning operations, contact a degreaser supplier that does, such as Ecolink. We have non-moisture and low-moisture degreasers that are suitable for a wide array of degreasing applications, from cleaning aluminium and copper engine parts, to cleaning carbon steel work tools, to cleaning stainless steel kitchen surfaces. Whatever you need in a degreaser, we can supply it.

If we do not carry a pre-formulated product that meets your moisture-free degreasing needs, our talented team of chemists will create a product that is formulated for your specific requirements. If you need a custom solution for using a degreaser to remove moisture, we can formulate the right type of product and supply it to your company on a regular basis for as long as needed.

For technical information about using a degreaser to remove moisture, or to inquire about receiving a custom formulated degreaser, call us today at (800) 563-1305, or fill out the contact form on our website. We look forward to helping you meet your moisture-free degreasing needs!