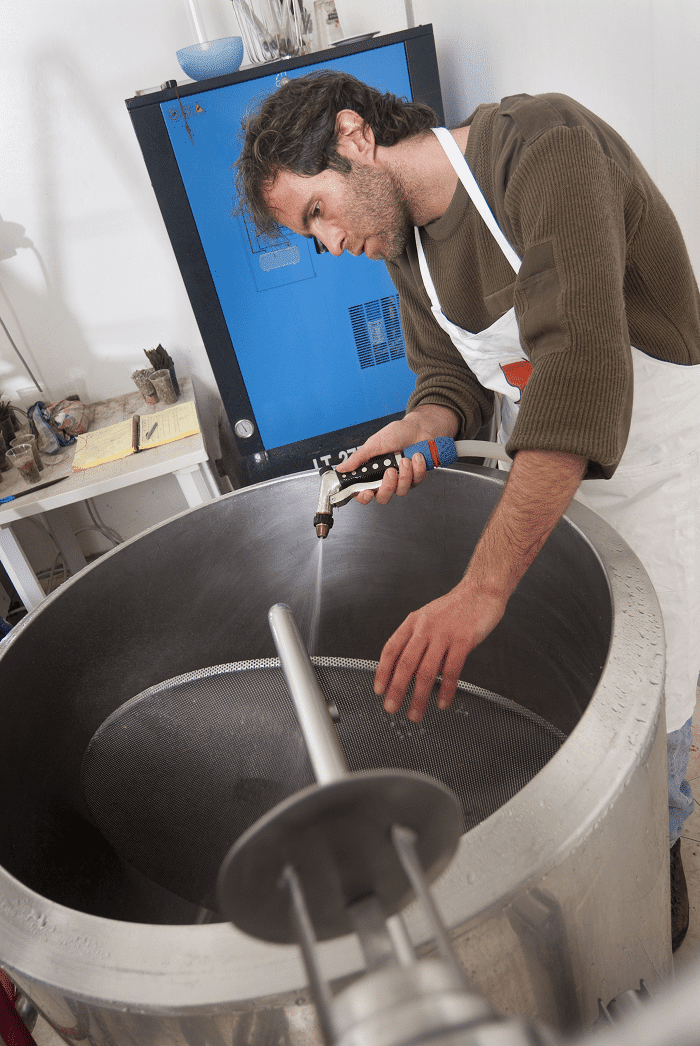

Tank cleaning is a process in which parts are placed inside a special tank that contains a cleaner for removing unwanted accumulations of dirt, oil, carbon and other substances that collect on parts. If your organization needs an environmentally preferred tank cleaner that efficiently removes accumulations that result from industrial work processes, New II Environmentally Preferred Parts Cleaner is an excellent option for the reasons listed below.

- MIL-PRF-680B Type II Compliant

MIL-PRF-680B Type II (a.k.a. mineral spirits) is a powerful cleaner for removing dirt, oil, carbon, and other substances from parts. However, the cleaner is also toxic to aquatic life, a skin irritant, and can cause drowsiness or dizziness in those who inhale its vapors. New II from Ecolink delivers the cleaning power of MIL-PRF-680B Type II without all of the dangerous drawbacks.

- No EPA Listed Hazardous Ingredients

New II is considered an “environmentally preferred” cleaner because it contains no ingredients that the Environmental Protection Agency (EPA) officially considers “hazardous.” In fact, although common sense chemical precautions should be taken while using the cleaner, it can typically be applied without the need for extensive personal protective equipment (PPE).

- No Cleaner Residue

New II is also an excellent tank cleaner because it leaves no residue. Instead, the solution evaporates quickly and leaves parts perfectly clean. Tank cleaner that deposits residue essentially thwarts the cleaning operation, as the residue can draw accumulations of dirt and grime much faster than they would occur if parts emerged from the tank residue-free.

- High Flashpoint

New II contains no flashpoint, which means that it is inflammable under all foreseeable conditions. This makes the solution a great drop-in cleaner replacement for a variety of different parts washing systems. In addition, the cleaner’s non-flammable formulation makes it easy to store beside combustible materials without causing a fire hazard in the storage environment.

- Non-Corrosive Formulation

New II has undergone numerous corrosion tests that demonstrate its effectiveness for cleaning various substances, including high-grade plastic, high-grade rubber, and metallic alloys that are prone to oxidize. While you should always check to see if a cleaner would cause a negative reaction in the parts you must clean, a non-corrosive cleaner usually prevents such a reaction.

- No Unpleasant Odor

Another benefit of choosing New II as your go-to tank cleaner is that it produces no noxious odors. If fact, unlike many toxic cleaners that New II can replace, the cleaner is odor-free. In addition to making the tank cleaning environment more pleasant to inhabit, the cleaning agent’s lack of odor helps prevent acute, negative health conditions (e.g., respiratory distress, dizziness, watery eyes, and upset stomach) that odorous, toxic cleaners often cause.

Let Us Supply Your Cleaner

If your organization needs a tank cleaner to replace MIL-PRF-680B Type II or another tank cleaner that has a dubious safety profile, New II Environmentally Preferred Parts Cleaner is an excellent option for a drop-in replacement. For questions regarding the use of New II on specific materials, or to place order for the cleaner, please call us today at at (800) 563-1305, or fill out the contact form on our website. We look forward to supplying you with a safer tank cleaner.