Industrial businesses and manufacturing companies that require industrial cleaning processes of parts, metals, products, components, and raw materials can add aerosol applications as a method of cleaning. Naturally, because there are several methods of cleaning industrial products – many of which are very safe and effective (though some are not so much) – it would be wise to mention what benefits are associated with using aerosol applications for industrial cleaning processes. The following will provide insight on advantages certain industrial organizations and manufacturing facilities can receive if it decides to transition to aerosol industrial cleaning applications:

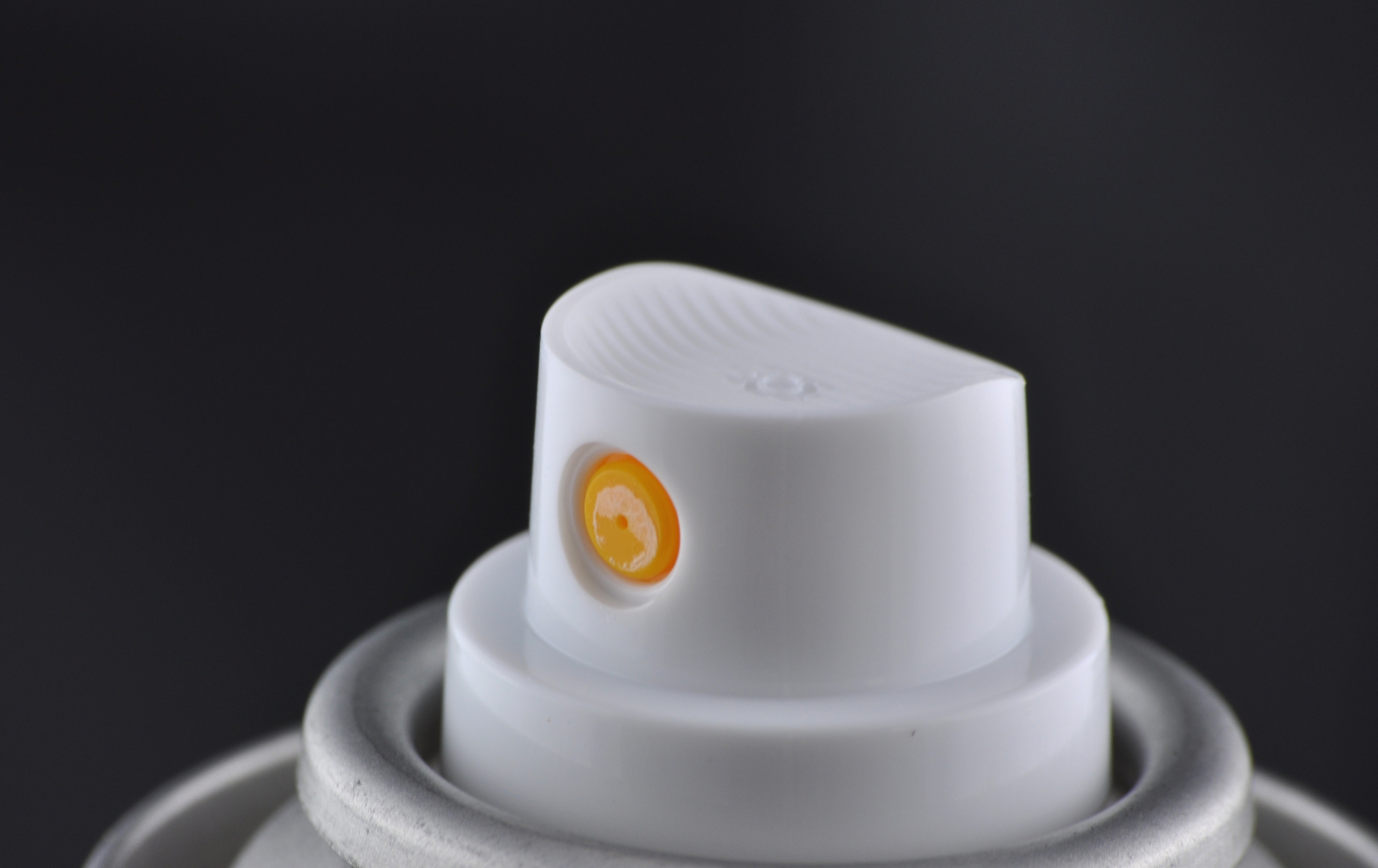

• Aerosol canisters are hermetically sealed, which prevents any leaking or accidental releasing of the contents. The aerosol containers are also resistant to tampering, and will also show evidence of tampering if someone did indeed try to physically open the canister.

• Aerosol applications eliminates the issues associated with leakages and spillages that stem from one of the more common methods of industrial cleaning, which is to use liquids. With the elimination of leakages and spillages, waste is practically eliminated, and the industrial cleaning application is much more efficient when an aerosol based cleaners is used. In other words, the aerosol applications are spill proof!

• With aerosol applications, it is much easier to manage the volume of applied cleaner, because aerosol containers are simpler to control. In other words, less cleaning solution will be lost, which means your industrial businesses will not have to buy as much cleaning solution, and can do so with less frequency, making aerosol applications a cost effective industrial cleaning solution.

• It is a lot simpler to avoid contact with an industrial cleaning solvent when applying it in aerosol cleaning solvent form, meaning the applier is in less danger of being exposed to harmful chemicals that could cause sickness and / or injury. Cleanup is much easier, and aerosol industrial cleaning solvents are more sanitary than any other types of cleaning solvent on the market at present.

• Aerosol cleaning solutions also dry much faster than any other kind of parts cleaning applications, which means the wait period for raw materials and components to be cleaned is dramatically reduced, which can drastically speed up production, along with whatever product process cycle your business has in place.

• Training employees and workers to use aerosol industrial cleaning applications is easier and less time consuming, therefore, you can trust in-house employees to take over the job of applying the parts cleaning application in your company’s parts cleaning facility, or facilities.

If your industrial organization is not already married to a certain cleaning solution for your products, components, and raw materials, then taking a serious look into switching to aerosol applications might prove a very advantageous venture that could improve the overall operations of your product process cycle.