Water cooling systems are a great addition to any manufacturing processes prone to producing excess amounts of heat. However, these processes often are unable to continue working efficiently if there is too much excess heat. This is why various systems are used to control the excess heat. In this blog, we will explain these various systems and what they can provide.

What are the different types?

There are six basic types of these systems:

- Liquid-to-Liquid

- Closed-Loop Dry System

- Closed-Loop Dry System with Trim Cooling

- Open-Loop Evaporative System

- Closed-Loop Evaporative System

- Chilled Water System

Liquid-to-Liquid Cooling System

The basic setup for this type of system would involve an intermediate heat exchanger. Water would be on one side and another coolant in a closed loop on the other side.

The system comes with the following benefits:

- Inexpensive to maintain

- Easy to maintain.

- Can be applied in exterior/interior spaces

And comes with the drawbacks of downtime for cleaning and requiring a certain amount of coolant to operate properly.

Closed-Loop Dry System

This type of system uses an air-cooled fluid cooler. The heat is transferred from a closed loop filled with water and pumped through rows of finned tubes.

This system possesses these benefits:

- Simple to install

- Low energy requirements

- Low maintenance

This system also possesses these drawbacks:

- Certain climate conditions

- Windspeed

- Limited location

Closed-Loop Dry System with Trim Cooling

The design of this system, although very similar to the previous one, contains an additional supplemental fluid cooler.

This design comes with the benefits of low cooling temperatures and small usage during colder months.

However, it contains the drawbacks of the system above.

Open-Loop Evaporative System

This system draws water through a honeycomb structure of PVC placed within a tower structure. The water inside the tower is evaporated and pumped back through the tower.

This design comes with the benefit of being inexpensive and simple to use in warmer climates

However, it does require extensive water treatment and possesses control issues in cooler weather

Closed-Loop Evaporative System

This system is a hybrid between an open tower such as the one prior and a closed-loop heat exchanger. The cooling water stays outside of the tower during the process.

Its benefits are minimal contamination and fewer water treatments.

While its drawbacks include different maintenance for each side and additional mechanisms.

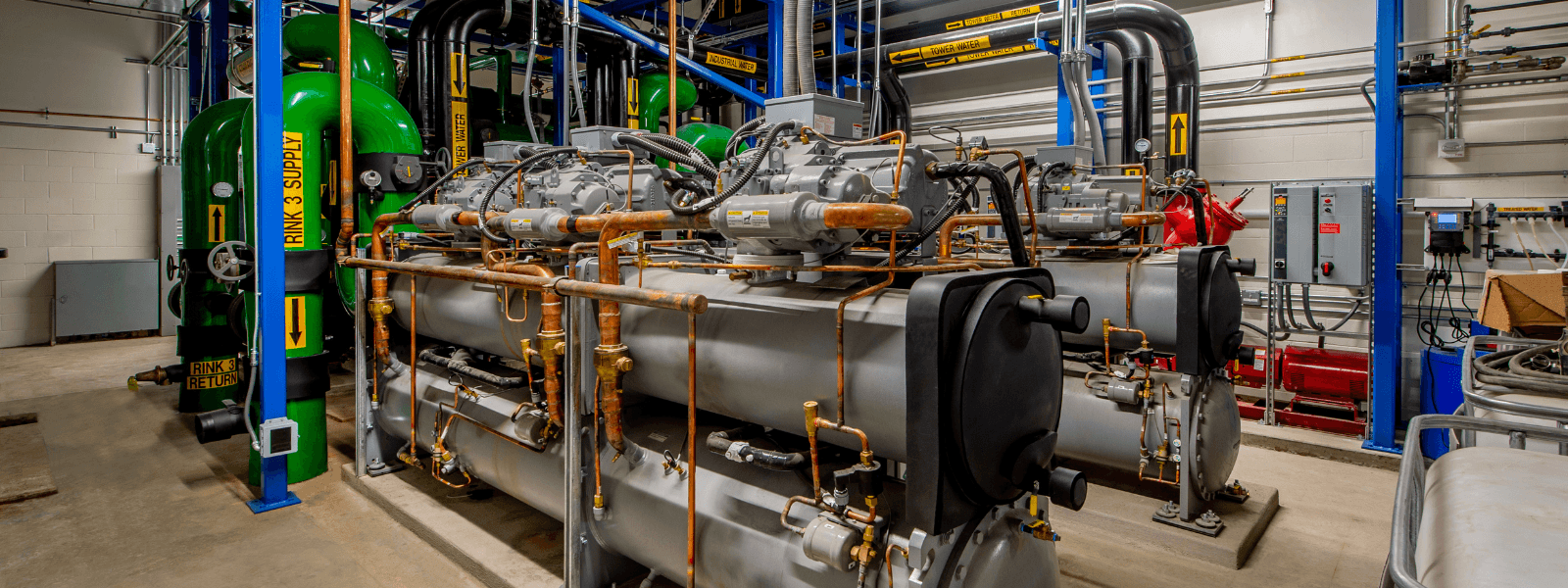

Chilled Water System

This system employs a compressor and a condenser to force cooling water through an evaporator, causing the process to cool down.

And comes with the benefit of being independent of the outside temperature.

However, its drawbacks include:

- Complex design

- Abundant heat,

- Requiring more power

- Not cost efficient

In need of more information about water cooling systems?

Then look no further than Ecolink! Here we have been dedicated to supplying industries like yours with chemicals for over thirty years! We also provide helpful blogs like this one, to guide you through all things chemical! Reach out to us today, we are here to help your industry thrive!