If you’ve ever walked outside on a hot day or exercised hard enough to feel warm, then you are familiar with the body’s natural tendency to sweat. By releasing hot water from your body in the form of sweat, your body is attempting to decrease your heightened body temperature. Basically, your body is releasing excess heat into the atmosphere to keep you cool off.

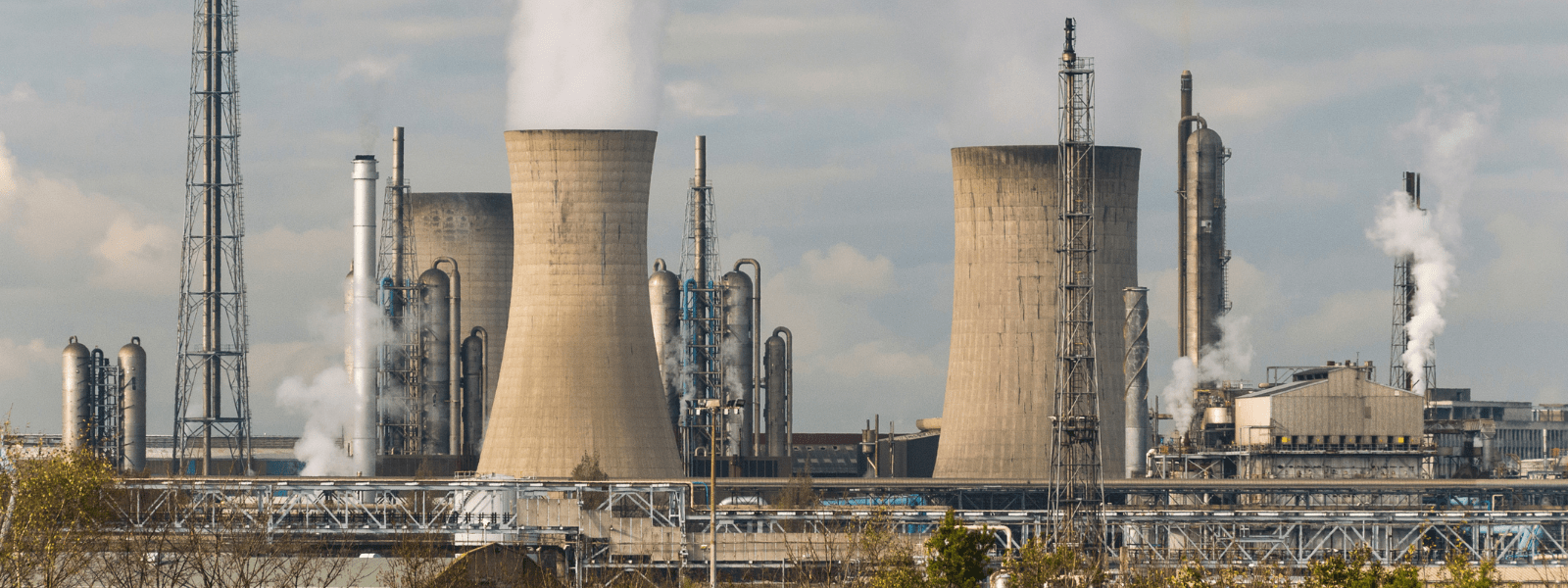

This is the same mechanism behind industrial cooling towers.

Cooling towers typically use water from open natural sources because of their abundance and reduced cost. But since the water from a lake or ocean contains tons of nutrients and microorganisms, sometimes these outside materials can build up and create fouling, which in turn can harm the internal structure and reduce the overall efficiency of the tower.

In this blog post, we’ll take a closer look at the best ways to reduce fouling in cooling towers.

Biofouling and Treatments

A lot of the fouling that occurs can be considered “biofouling,” which refers to the buildup of living material, such as:

- Bacteria

- Algae

- Fungi

- Barnacles

- Mussels

Biofouling can be reduced by periodically or continuously flushing the system with biocides. Biocides or antimicrobial chemicals are designed to kill organisms or prevent them from reproducing.

Particulate Fouling and Treatments

Sometimes fouling is caused not by organisms, but by particles suspended in water that enter through the water intake and settle in the system. This is controlled mainly by the water velocity (how quickly it is moving down through the tower) and the size of the particles in the system.

Particulate matter is mainly made up of insoluble minerals, such as:

- Aluminum

- Iron

- Silt

- Clay

This matter may enter as small molecules, but as the water is recirculated, it can coagulate (clump together) to a more troublesome size.

There are several methods of dispersing particulate fouling, including:

Filtration

Filtering water before it recirculates can greatly reduce the amount of larger particulates entering the system, but may not be effective against fouling that forms and settles.

High Water Velocity

If your system can handle a higher velocity of water, this method can be effective against silt and clay deposits. Other foulants, such as aluminum and iron are “stickier” and may not be affected.

Dispersants

Dispersants work by attacking suspended particles and giving them a high electric charge, making them repulsive to each other. This method prevents the clumping of particulates and also reduces the attraction between particles and the structure.

Surfactants

Surfactants are basically soaps that work similarly to dispersants by reducing the electrostatic attraction between the surface of the system and the particles attached to it.

Fouling Problems in Your Industrial Water System?

Let Ecolink help you reduce and prevent fouling in your industrial equipment. Reach out to one of our knowledgeable experts to learn the best method and product for your needs!