Acetone, or dimethyl ketone, is a popular liquid in chemistry and industries. It is colorless and potent in various industrial applications. This...

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

Why can’t you use soy methyl ester for cleaning shingles?

The answer is fairly simple: that’s not what it’s for! You need to clean your shingles before you use a soy methyl ester (a.k.a. methyl soyate)...

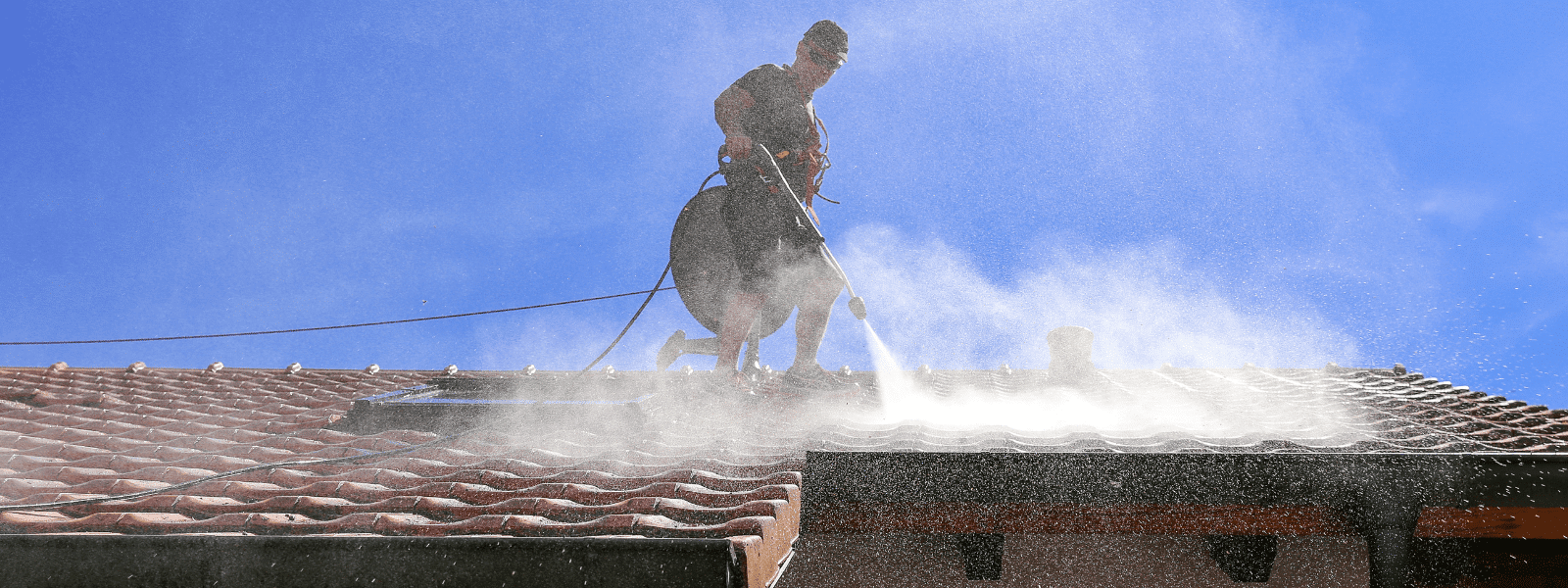

What Is Non-Pressure Chemical Cleaning?

Non-pressure chemical cleaning, also known as soft washing, is a method that eliminates the use of extreme pressure when cleaning a roof. When it...

Katelynn’s Internship Experience

Since my summer internship with Ecolink has come to a close, I would like to take a moment to reflect on all the new...

Why can’t you use soy methyl ester for cleaning shingles?

The answer is fairly simple: that’s not what it’s for! You need to clean your shingles before you use a soy methyl...

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.