Resin can be both naturally occurring and synthetically made. It is a viscous substance: when cured, it becomes a rigid polymer-like substance....

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

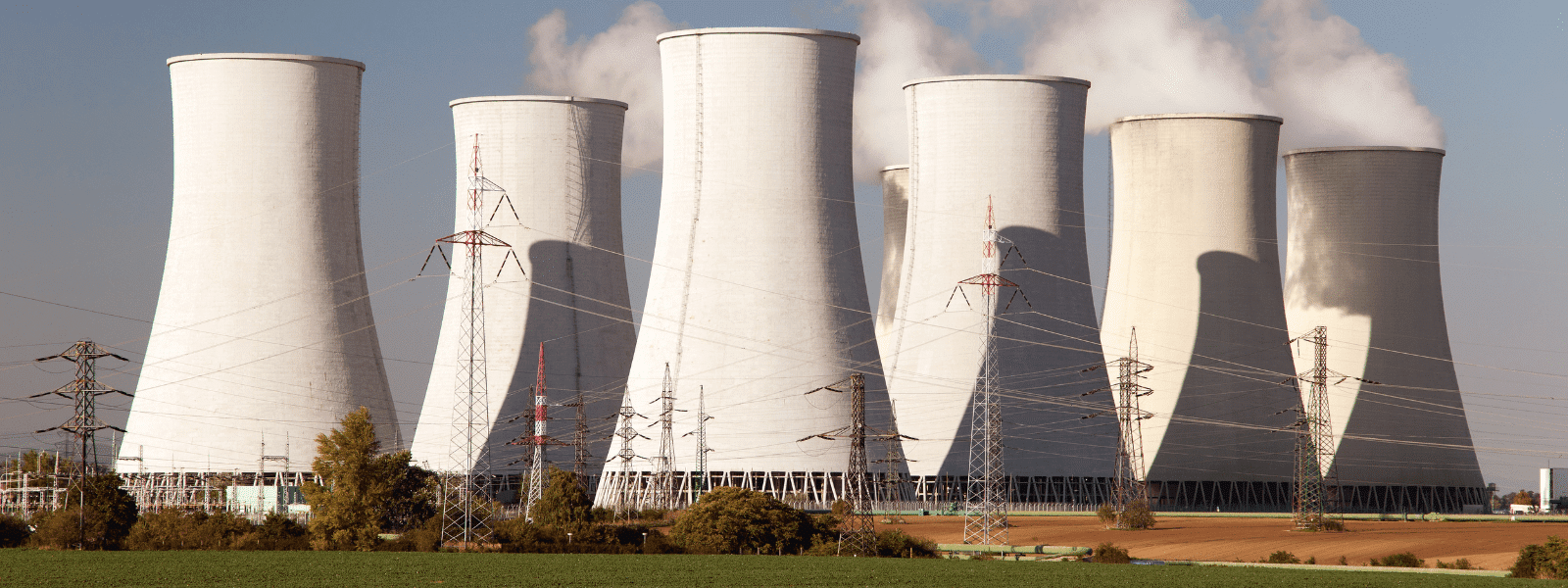

Best Ways to Remove Biofilm from Cooling Towers

Biofilm, or the slick, slimy layer of microorganisms that can form on any surface, can cause real problems for cooling towers. Whether it blocks the...

Why Is There Biofilm in Cooling Towers?

If you’ve ever been around a natural body of water during warm weather, you may have observed a slimy layer of scum accumulating on the surface of...

Where Can I Find a Safe Paint Remover?

Finding a safe paint remover on the market, whether industrial or commercial, can be surprisingly difficult. Many...

Best Ways to Remove Biofilm from Cooling Towers

Biofilm, or the slick, slimy layer of microorganisms that can form on any surface, can cause real problems for cooling...

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.