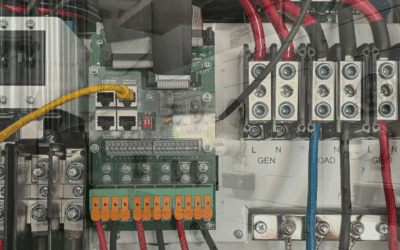

Manufacturers utilize various electrical equipment for industrial tasks daily. Electrical equipment can aid in production time and complete tasks...

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

Environmentally Friendly Fuel: Promoting Sustainable Practices

As environmental concerns continue to grow, businesses are recognizing the importance of using ecofriendly fuel. Traditional fossil fuels have long...

Aerosol Coating: Efficient Spray Solutions for Industrial Use

In the world of industrial surface coating, aerosol coating has gained popularity as an efficient and versatile spray solution. Aerosol coating...

Alternative Fuels Examples: Innovations in Industrial Energy

In the sustainability and reduced environmental impact, many businesses are turning to alternative fuels as a viable...

Environmentally Friendly Fuel: Promoting Sustainable Practices

As environmental concerns continue to grow, businesses are recognizing the importance of using ecofriendly fuel....

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.