Filling out applications and interviewing for internships can sometimes be incredibly nerve-racking. You might wonder if you have what it takes to...

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

Valerie’s Internship Experience

Now that the spring internship is coming to an end, I am reflecting on all the skills I have learned and the connections that I’ve made while...

Zoe’s Internship Experience

As an English major specializing in Creative Writing, I often faced judgment from peers and older adults in my life for not picking what they would...

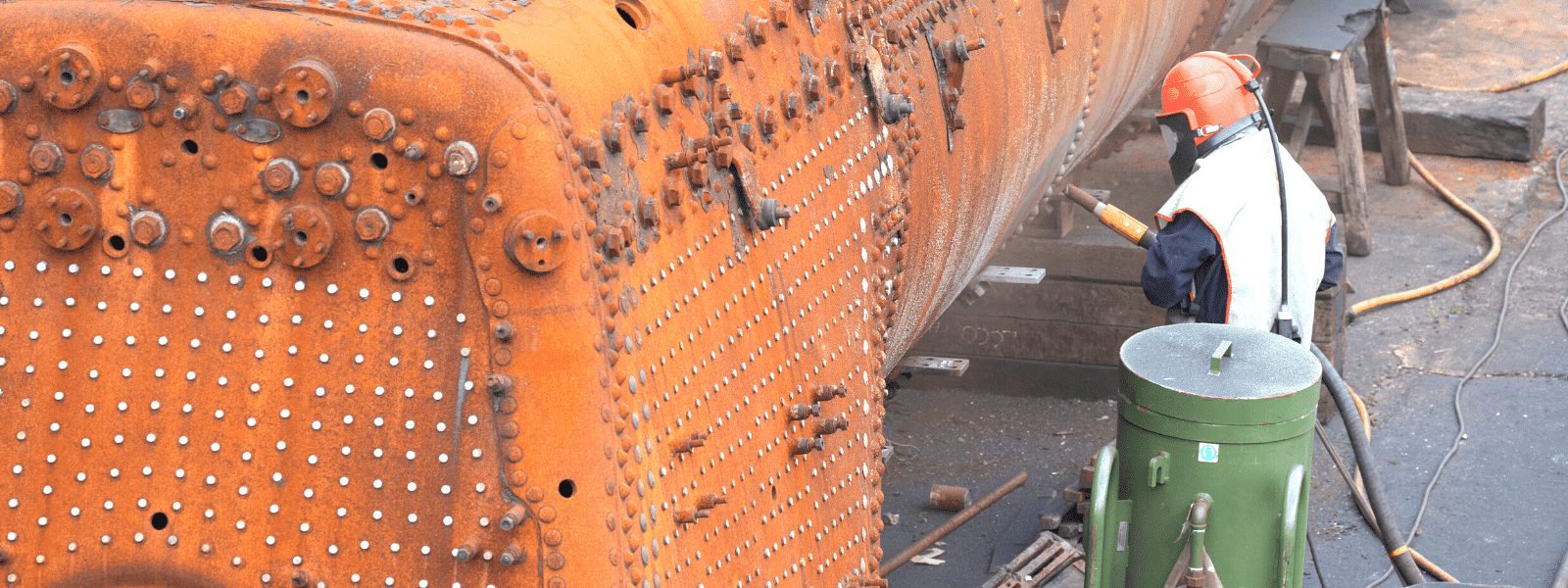

Industrial Degreasing Solvents

Are you interested in learning about industrial degreasers and how they can benefit your business? This blog post will...

Valerie’s Internship Experience

Now that the spring internship is coming to an end, I am reflecting on all the skills I have learned and the...

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.