Paint strippers or paint removers are chemical products that separate paint from surfaces. These chemical products are well-sought-after when...

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

What Is Biofouling Prevention?

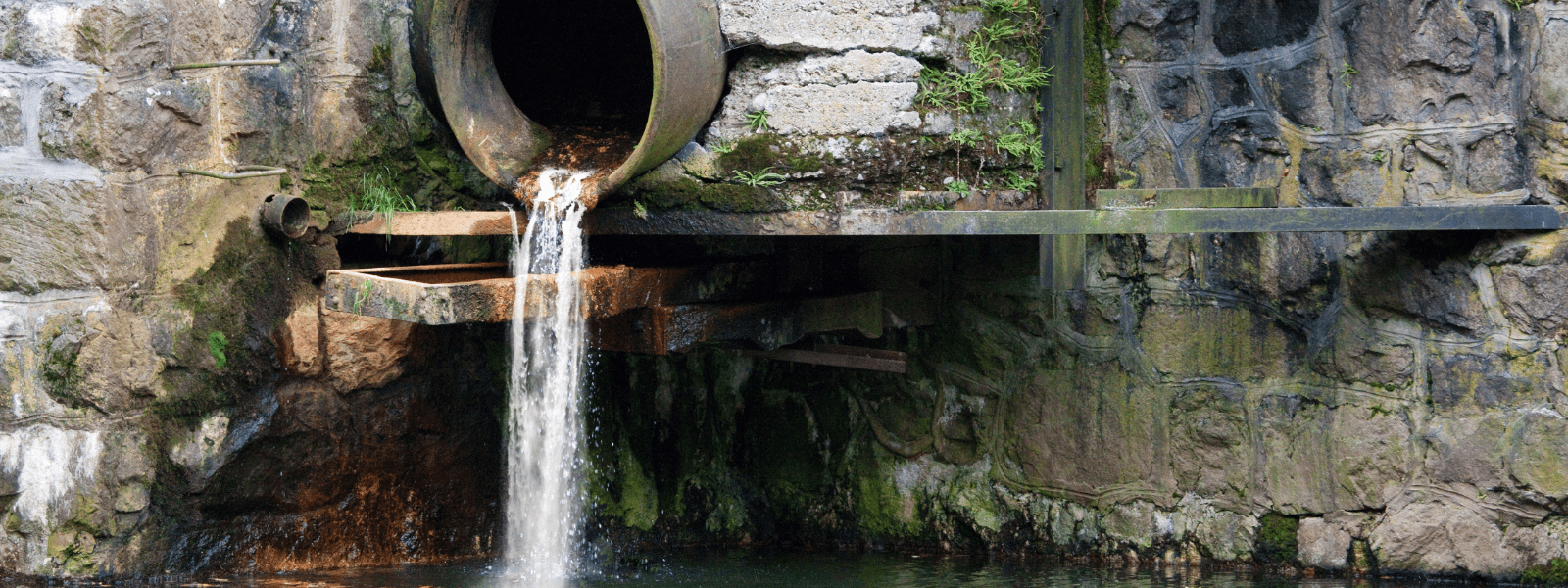

Biofouling refers to the unwanted build-up of biological materials, such as bacteria, algae, or other microorganisms on surfaces submerged in water....

Biofouling Prevention Treatment

If you’ve ever swam in a natural body of water, you may be familiar with the slimy greenish-brown scum that accumulates on most submerged objects....

Biofouling and Biofilm Treatment Explained

Biofouling is the buildup of organic materials, typically small plants, microorganisms, or algae on submerged...

What Is Biofouling Prevention?

Biofouling refers to the unwanted build-up of biological materials, such as bacteria, algae, or other microorganisms...

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.