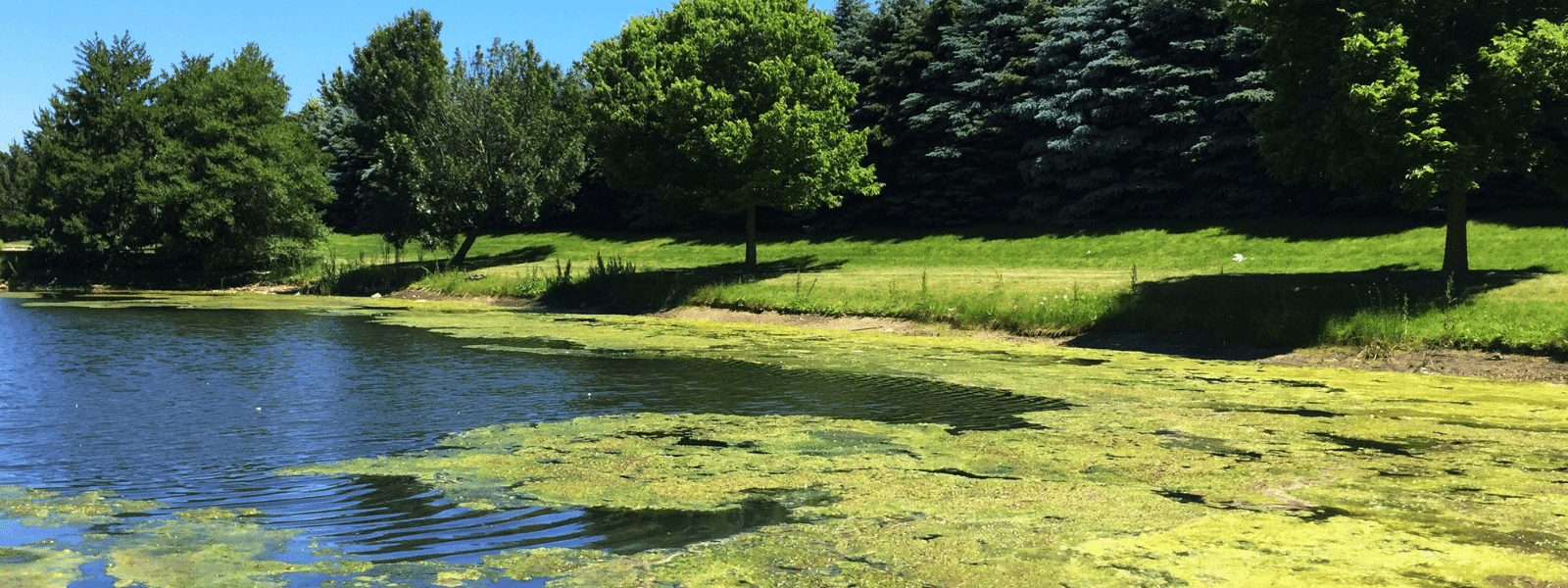

Algae is a simple plant and only needs a few things to prosper: water, sunlight, and nutrients like carbon, nitrogen, and phosphorus. This simple...

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

History of Women’s Chemical Exposure to Household Chemicals

Every job has different day-to-day responsibilities, just as every job has different tools—a sports newscaster needs a microphone, and a plumber...

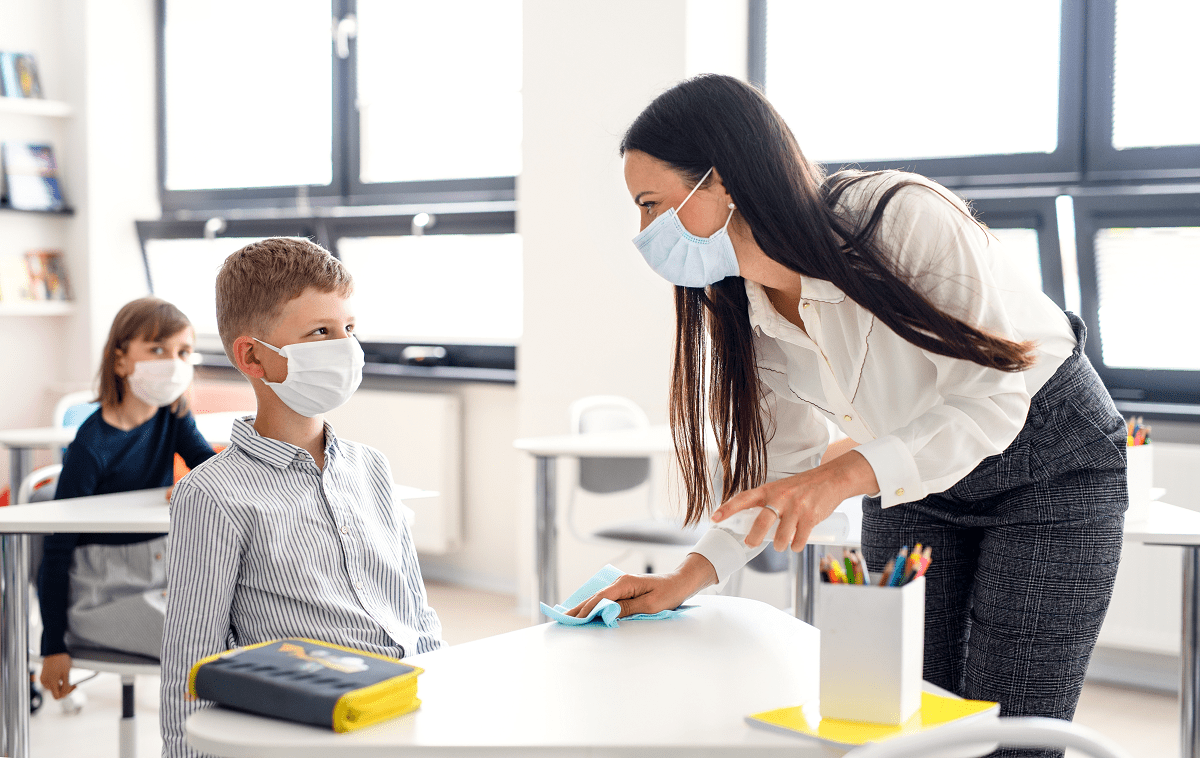

Green Cleaning At School – Kellina Brennan

Because germs are invisible, we become quietly lulled into a false sense of security- a peace shattered with the worldwide COVID-19 pandemic. The...

Getting to Know Thomas Brennan

Getting to Know Thomas Brennan Thomas Brennan is currently a freshman at Christopher Newport University and is one of...

History of Women’s Chemical Exposure to Household Chemicals

Every job has different day-to-day responsibilities, just as every job has different tools—a sports newscaster needs a...

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.