If you’ve ever been around a natural body of water during warm weather, you may have observed a slimy layer of scum accumulating on the surface of...

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

“Clean Ideas Start With Me” – Naomi Davis

“99.9% effective at killing illness-causing germs and bacteria”. But at what cost? Surely many of us have had this revolutionary slogan embedded...

Getting to Know Naomi Davis

Naomi Davis is a student at the University of Central Florida, studying social work. She is one of Ecolink’s six $500 scholarship recipients. We...

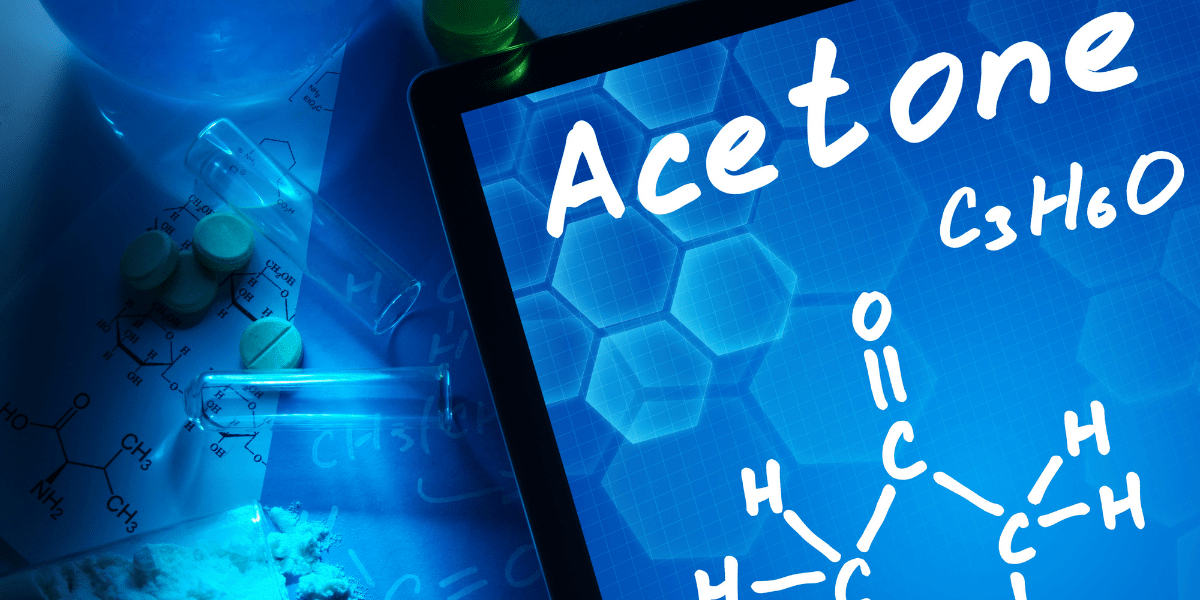

Acetone For Cleaning Metal

Can you use acetone for cleaning metal? Yes, you can! Acetone is well known as one of the safest solvents to use for...

“Clean Ideas Start With Me” – Naomi Davis

“99.9% effective at killing illness-causing germs and bacteria”. But at what cost? Surely many of us have had this...

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.