What is Trichloroethylene used for? Trichloroethylene, also known as TCE, is a popular organic solvent used in both industrial and commercial...

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

Getting to Know Kellina Brennan

Kellina Brennan is currently a senior in high school and is one of two of Ecolink’s one-thousand-dollar scholarship recipients. We wanted to get to...

Laura Augustine Spotlight

"Do as A Woman Would Do It" Laura Augustine’s Beginnings in Industrial Chemicals For Laura Augustine, it all started with a newspaper ad. After...

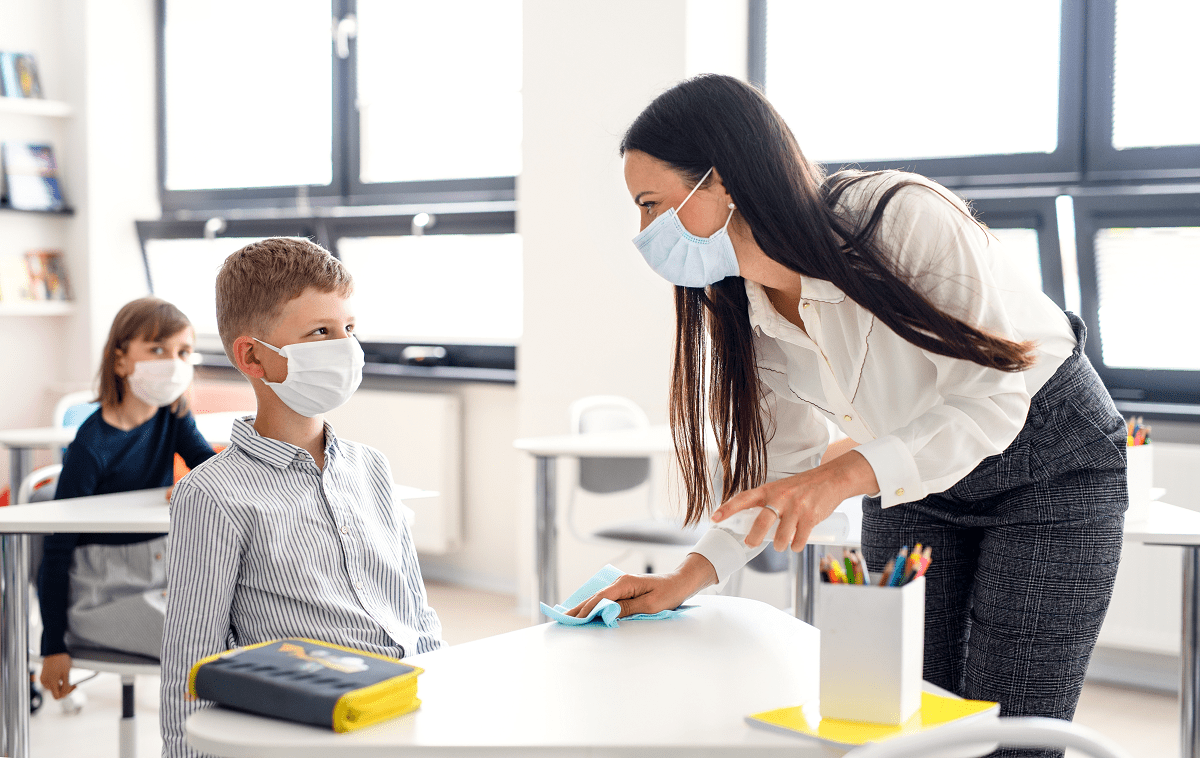

Green Cleaning At School – Kellina Brennan

Because germs are invisible, we become quietly lulled into a false sense of security- a peace shattered with the...

Getting to Know Kellina Brennan

Kellina Brennan is currently a senior in high school and is one of two of Ecolink’s one-thousand-dollar scholarship...

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.