Looking for reliable Isopar G suppliers? Ecolink provides high-quality isoparaffinic hydrocarbon solvents with expert technical support, competitive...

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

Best Vehicle Degreasers: Efficient Solutions for Removing Grease

fleets for their operations. Grease buildup can hinder efficiency and diminish the overall aesthetics of vehicles. To combat this challenge,...

Vehicle Maintenance: Keeping Your Fleet in Top Condition

For many business operations, a well-maintained fleet of vehicles is not only a functional necessity; it is a reflection of a company’s commitment...

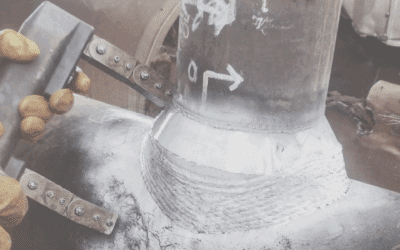

What is Non-Destructive testing? A Brief Overview

Evaluating a product’s materials and internal components is one of the best ways to test the integrity of a...

Best Vehicle Degreasers: Efficient Solutions for Removing Grease

fleets for their operations. Grease buildup can hinder efficiency and diminish the overall aesthetics of vehicles. To...

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.