Solvents, as reliable and popular as they are, are not all as safe as one would expect. Unfortunately, those that are most commonly utilized by...

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

Benefits of Tidal Oven & Grill Cleaner

Interested in a New Industrial Kitchen Cleaning Solution? If so, check out Tidal Oven & Grill Cleaner. This alkaline solution, whose main...

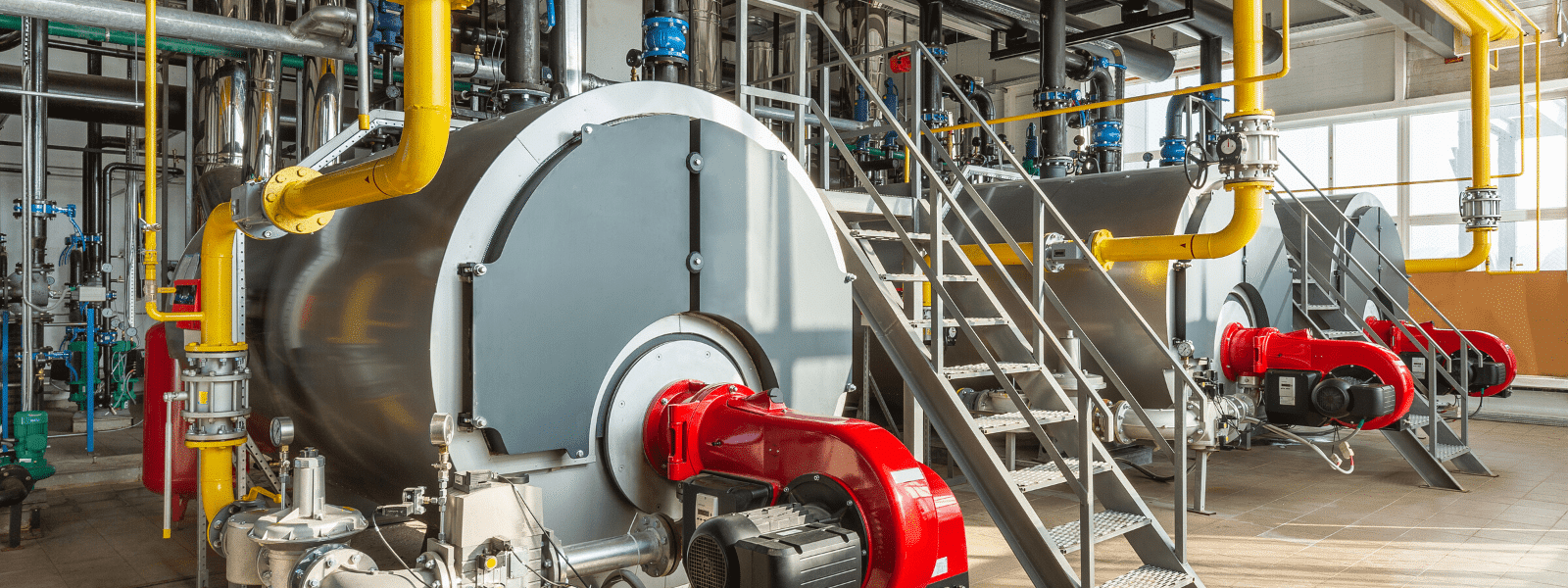

What is the Purpose of Chemically Treating Boiler Water

One of the biggest issues that occur with boilers is the hardening of water, which is the main cause of corrosion of metal and scale buildup in the...

What Chemical is added to Control Hardness in a Boiler?

One of the problems that may occur when using a boiler is water hardness, which is the primary cause of sludge or...

Benefits of Tidal Oven & Grill Cleaner

Interested in a New Industrial Kitchen Cleaning Solution? If so, check out Tidal Oven & Grill Cleaner. This...

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.