For almost all industrial processes, especially those involving manufacturing operations and mechanical machinery, it is essential to maintain a...

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

The History of Recycling

What is Recycling? Recycling is converting or repurposing waste into a new, usable product, allowing its lifespan to provide a variety of...

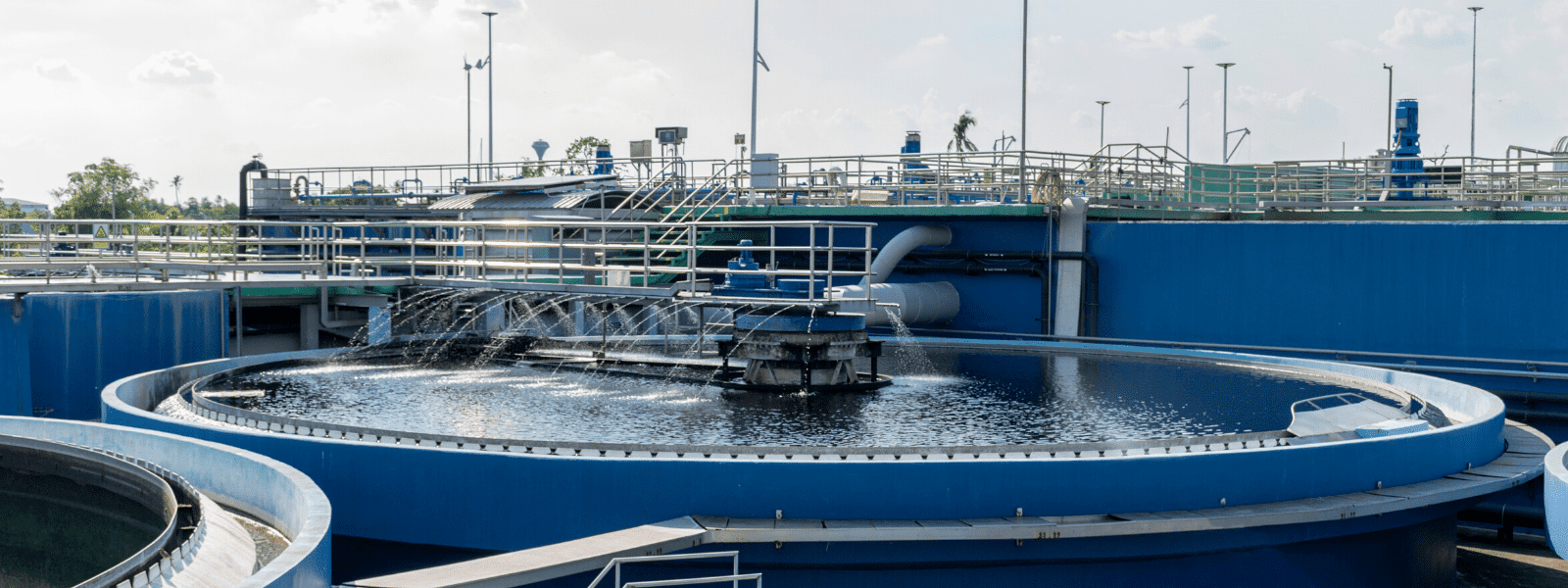

What are the 4 Steps of Water Treatment

Water treatment follows a process of four steps. Follow along with the Ecolink team as we walk you through the 4 steps of water treatment. If you...

The Benefits of Tidal Shine Plus

Are you looking for an industrial-strength truck cleaner? If so, check out Tidal Shine Plus. Tidal Shine Plus is an...

The History of Recycling

What is Recycling? Recycling is converting or repurposing waste into a new, usable product, allowing its lifespan to...

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.