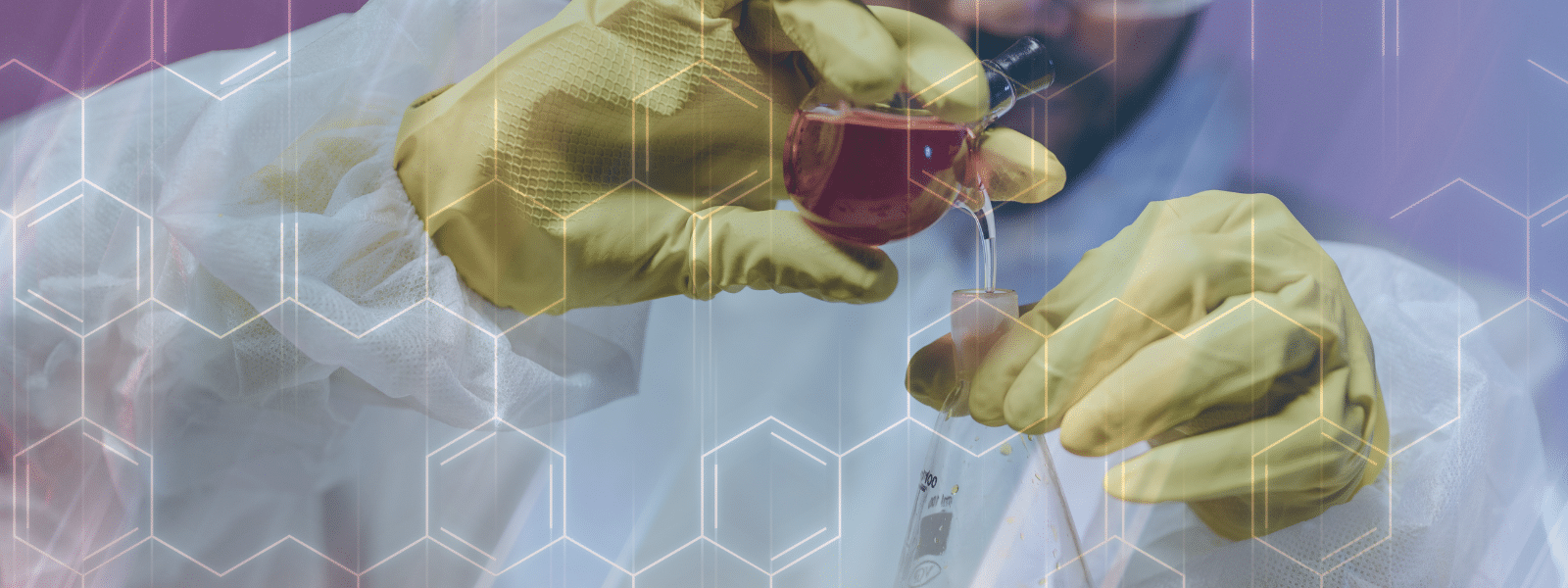

Proper chemical treatment is essential for disinfecting water and preventing buildup in boilers. But what other benefits are there? In this blog...

Blog

CHEMICAL INDUSTRY NEWS

Chemical Chat – Discover What’s New!

Top 3 Electrical Cleaning Solvents to Extend Equipment Life

Manufacturers utilize various electrical equipment for industrial tasks daily. Electrical equipment can aid in production time and complete tasks...

Industrial White Oil: Applications and Benefits in Different Sectors

White oil, also known as mineral oil is a colorless mixture of hydrocarbons obtained from petroleum. Manufacturers from multiple industries use...

Cleaning Electrical Contacts: 5 Tips for Effective Maintenance

Electrical contacts are important circuit components found in machines and electrical equipment that are made from...

Top 3 Electrical Cleaning Solvents to Extend Equipment Life

Manufacturers utilize various electrical equipment for industrial tasks daily. Electrical equipment can aid in...

Company News

Managed Services

Discover the Latest in Safe and Sustainable Chemical Solutions

Stay informed with Ecolink’s blog! Subscribe now

Chemical Management Information

Stay updated with us

Sign Up for the Latest Updates

Stay informed about chemical supply chain disruptions and emerging innovations to keep your business at the forefront of efficiency and innovation. Uncover new ways to make your business practices more sustainable by incorporating safer products into your cleaning lineup.