Chemical manufacturing is a subsector of the manufacturing industry. In most situations, it is performed using one of two methods: continuous processing, in which raw materials are continually fed into the manufacturing vessel, as the finished chemical is removed to create room; and batch processing, in which raw materials are placed in the vessel for longer periods of time, particularly to perform quality control checks or refine the batch through cleaning methods.

Is One Process Better Than the Other?

From the standpoint of producing the desired chemicals, batch manufacturing and continuous manufacturing are equal. Depending on the desired qualities of the product and the needs of the end user, one process can be just as efficacious as the other. However, especially for the chemical manufacturer, the processes do possess some meaningful differences.

For example, continuous processing is ideal for completing large work orders, as the chemical is constantly produced until the order is filled. Imagine heat treating steel in a continuous furnace that perpetually moves workpieces through the heating chamber on a conveyor belt. In terms of function, this is similar to what continuous chemical manufacturing is like. Now, imagine sequestering the same workpieces in the chamber of a vacuum furnace until they attain the desired metallurgical qualities. This is similar to what batch chemical manufacturing is like.

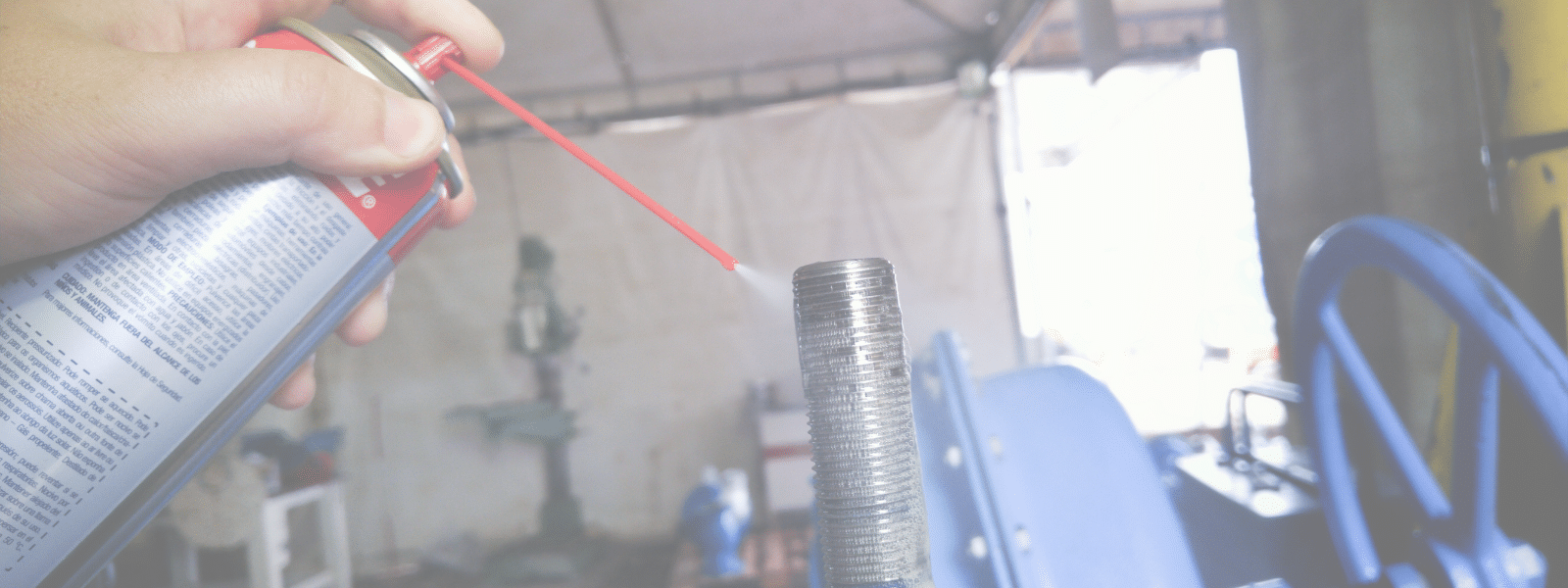

In addition to being ideal for completing large orders, continuous chemical manufacturing may involve more emissions than its counterpart, batch processing. The emissions may not increase to a level where emission caps from the Environmental Protection Agency (EPA) come into play, but they can impact the health of workers who inhabit the environment where chemicals are produced. If the chemicals in question are hazardous, a special ventilation system and high-level personal protective equipment (PPE) are often used to mitigate the effects.

What Determines Which Process is Used?

Batch processing is the industry standard for efficiently producing small batches of chemicals that meet unique end user requirements. In many cases, the manufacturer produces a sample solution, forwards it to the customer, and awaits feedback regarding what must be done to perfectly customize the product for the application. Consequently, small batch chemical manufacturing is commonly associated with the production of custom chemical products.

Continuous processing, on the other hand, is the industry standard for producing large volumes of chemicals, which are typically designed to meet the needs of a broad range of end users. For example, in terms of efficiency and cost, it may make more sense to use continuous processing to create a dielectric solvent that is widely used by companies in the aerospace industry. In continuous processing, supply and demand are key considerations. The manufacturer often refers to production data from the previous year, as well as industry trends, to gauge production.

Contact Ecolink for Chemical Manufacturing

Through investments in high-tech manufacturing equipment and top talent, Ecolink has the capability to batch produce custom chemicals that meet the needs of your company or organization. We also offer widely used solvents that are applicable to a variety of industries. If you need a new chemical solution, we will suggest the best option for your needs, and deliver it with a quick turnaround time. Call us today at (800) 563-1305, or refer to our contact page.