One of the biggest problems that water cooling systems can face is corrosion, which occurs when water interacts with the metals in the structure and causes it to deteriorate. The most common example is rust, which is the result of water oxidizing iron. Cooling water systems, especially those with large amounts of iron, can be susceptible to rust, but other types of metal can also corrode

Just like garden tools that become brittle and weakened by rust, cooling systems can be greatly damaged. However, there are ways to mitigate this damage, such as including additives in the water to prevent corrosion.

Examples of Anti Corrosion Additives

Depending on the type of metal that you are defending, and the temperature and pH of the water, different chemical additives will be more effective. Here are a few examples of common chemicals used:

- Zinc

- Molybdate

- Polysolicate

- Polydiol

- Azoles

- Nitrate

- Polyphosphates

- Ortho-phosphates

It should be noted that chromate was traditionally used as a steel anti-corrosion additive, however, it has been banned by the EPA because of its toxicity and environmental harms. For all the Julia Roberts fans out there, you might remember the villainous Chromium-6 (a derivative of chromate) from Erin Brockovich, which was used as a rust inhibitor for cooling towers and caused serious health problems for the residents of a nearby town.

The real-life case of Anderson et al. vs Pacific Gas and Electric (which the movie is based on) was the largest settlement of a direct-action lawsuit in the history of the United States at that time in 1996. Many of the chemicals listed above were developed as safer alternatives.

What Causes Corrosion

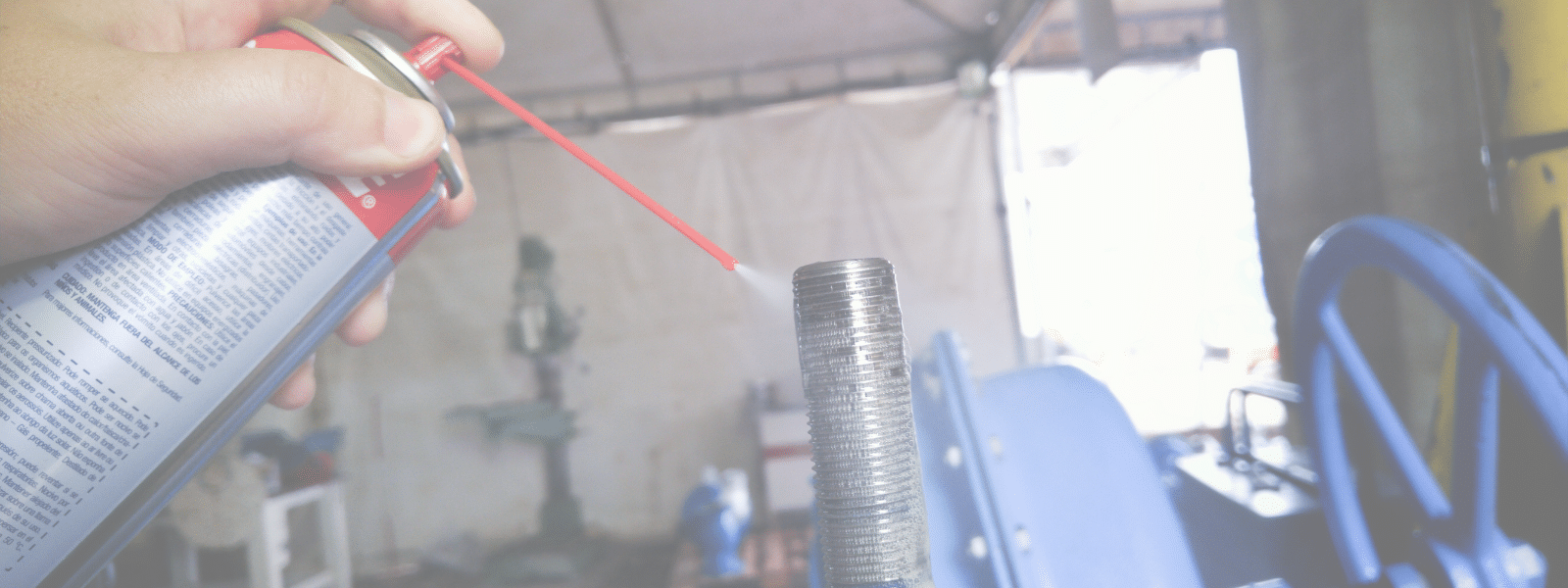

Corrosion is a chemical process that involves the transfer of electrons. Free oxygen atoms contained in water remove electrons from the surface of the metal in a process known as oxidation. This process involves 3 parts:

1. Anode: the metal from which electrons are being removed

2. Cathode: the metal receiving excess electrons

3. Electrolyte: the medium capable of transferring electrons, in this case, water with oxygen

To satisfy their electronegativity, the oxygen atoms will remove electrons from the anode, and combined with water and oxygen, these electrons will become hydroxide ions (an ion is a molecule with a charge).

Simultaneously, some of the oxygen will also dislodge metal ions from the cathode. These metal ion particles will combine with the hydroxide ions to form metal hydroxides, such as iron oxide (rust). This process makes corrosion a twofold danger; it deteriorates the metal and deposits new material which can create blockages.

Most inhibitors work by creating a protective film over the anode or cathode, which can be the same metal. That way the free oxygen cannot penetrate to start the process.

Interested in Cooling Water Anti Corrosion Additives?

Understanding the risks of deterioration to a cooling water system may induce worry. However, here at Ecolink, we are dedicated to keeping your industrial systems working properly.

For more information on additives for fighting corrosion, or to learn how to best protect your water-cooled system, please reach out today!