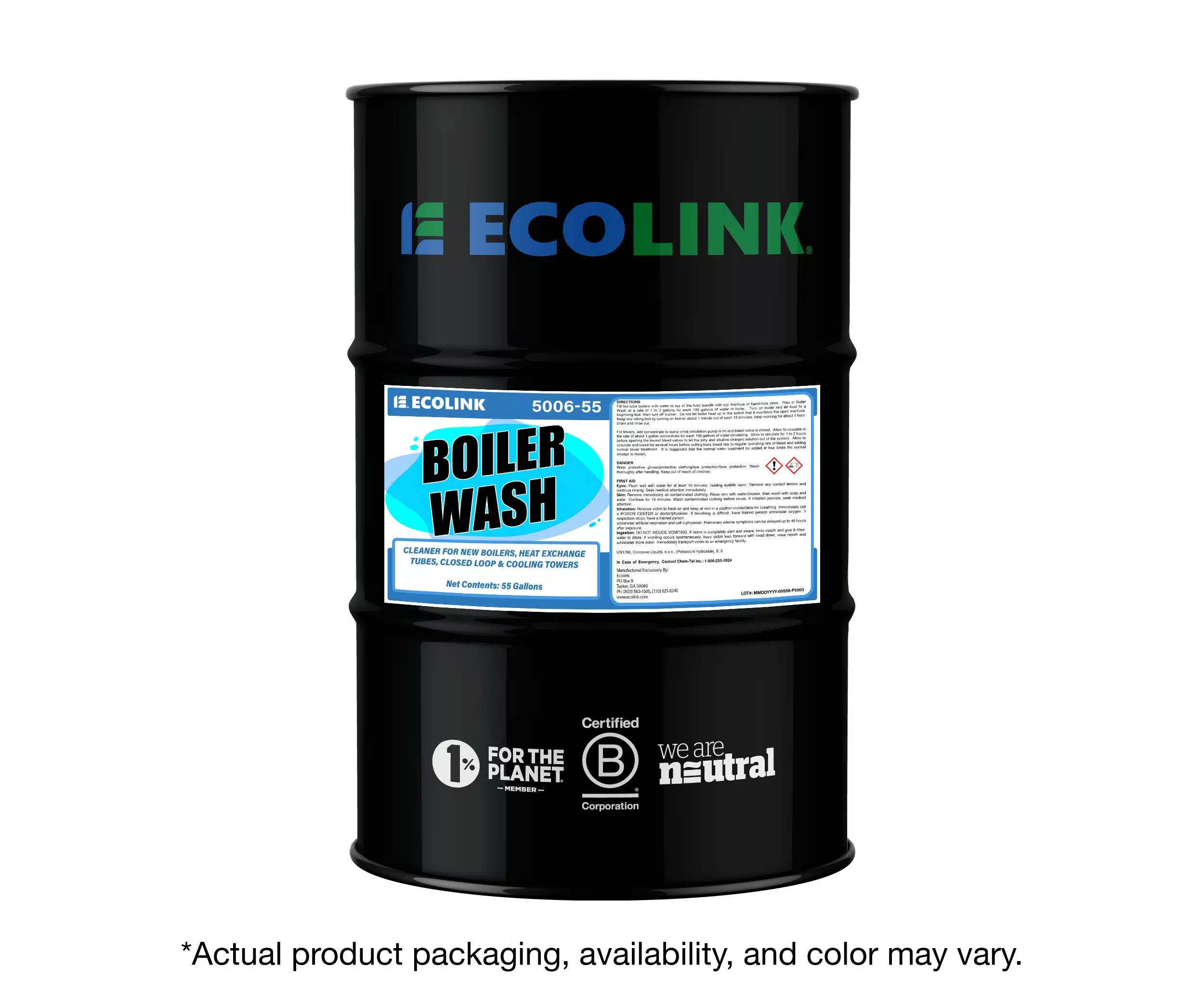

Boiler Wash – 55 Gallon Drum

Ecolink requires a $600 minimum order. MOQs may apply to some items. Learn how to buy with Ecolink.

In stock

Boiler Wash – 55 Gallon Drum

Boiler Wash is a solution that can be used to cleanse new boilers, offline boilers, closed loops, heat exchange tubes, surfaces, and towers.

$ 742.93

Description

Boiler Wash - 55 Gallon Drum

Boiler Wash is a clear, alkaline solution that contains 2-butoxyethanol, disodium trioxosilicate (both 0%-4% by concentration), and potassium hydroxide (3%-8% by concentration). It eliminates scale, corrosion, oil, grease, and rust from new boilers, closed loops, heat exchange tubes, surfaces, and towers. It can also be used on boilers that have been taken offline.

Boiler Wash Benefits:

- Low reactivity

- Removes numerous types of dirt and grime

- Sold in a bulk 55-gallon drum for industrial use

Boiler Wash Applications:

- Boiler Wash is a water treatment solution that can be applied to new boilers, offline boilers, closed loops, heat exchange tubes, surfaces, and towers to expel oil, grease, scale, corrosion, and rust.

- For fire-tube boilers, the boiler must be filled with water with the top manhole or hand-hole open. Then, Boiler Wash may be added at a rate of 1-2 gallons per 100 gallons of water.

- The boiler should be turned on, allowed to heat up, then turned off once the water is boiling.

- It can be switched back on for about 1 minute every 15 minutes for an hour, ensuring that the water does not overflow. Then, the boiler may be drained and rinsed out.

- For towers, Boiler Wash should be used at a rate of 1 gallon per 1,000 gallons of water.

- It must be added while the bleed valve is closed and the circulation pump is on, then permitted to circulate.

- After 1-2 hours, the lowest bleed valves may be released to allow the dirty solution to drain out.

- Boiler Wash can be left to circulate and bleed for a few hours.

- Finally, the bleed rate can be returned to its regular rate, and normal tower treatment can be administered at 4x its regular dosage.

GOT QUESTIONS?

FAQ

EXPLORE OUR PRODUCTS

Product Categories

YOU MAY ALSO LIKE

Related products

HAVE QUESTIONS?