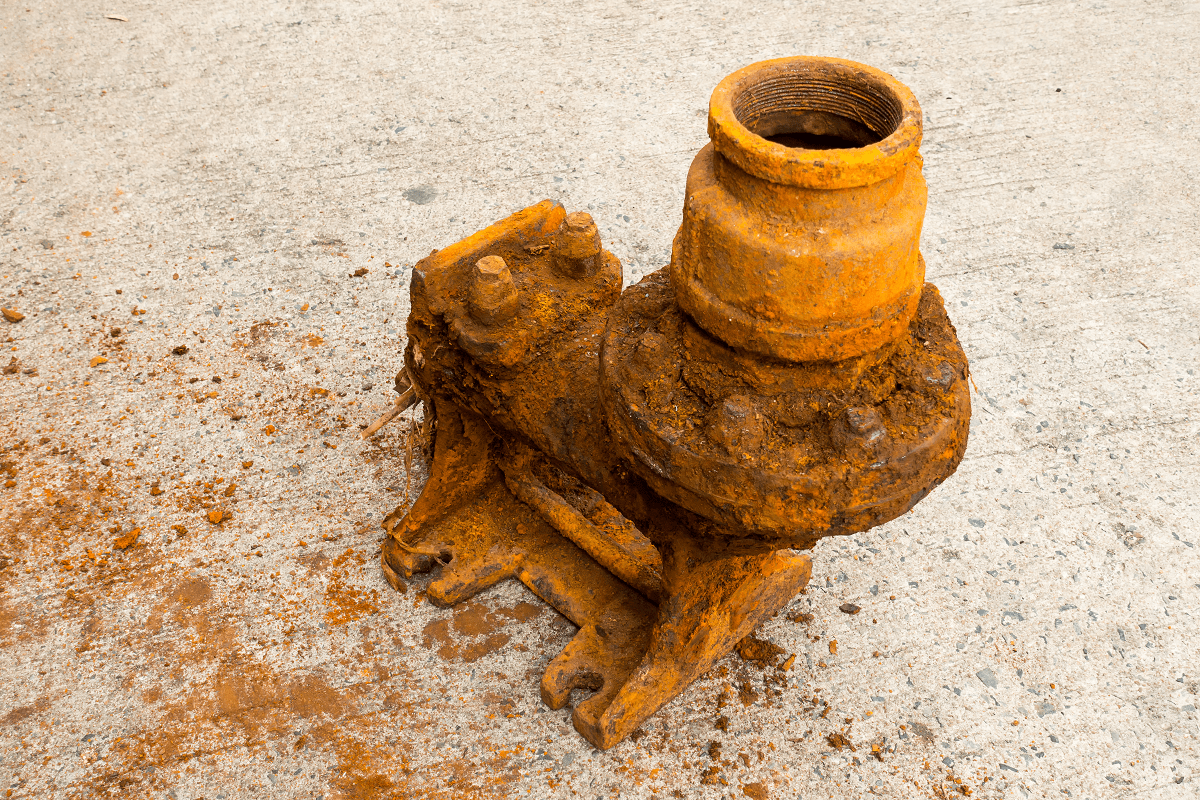

We often think of rust (a.k.a. iron oxide) as primarily affecting iron alloys that are subjected to the elements, particularly oxygen and water. Car frames, sheet metal, and metal fixtures on objects such as telephone poles are prime examples of products that reinforce the view.

However, even equipment that’s never been outdoors can rust when the right conditions are present. Using stainless steel that shuns oxygen and moisture induced corrosion can help, but the best way to counteract rust is to create a work environment that doesn’t foster rust.

If this is impossible, and your equipment experiences rust, you have two option for removing the unsightly chemical reaction: using an industrial rust removal solvent or performing manual rust removal.

Solvent Rust Removal

The easiest way to remove rust is applying an industrial rust removal solvent, such as Rust Rip from Ecolink. Applying the solvent to a rusted area causes rust to flow away and leave the underlying metal rust-free. However, this option is best for rust accumulations that haven’t yet caused the metal to pit and allow rust to progress deeper in the structure.

If heavy pitting is present, rust will be removed and the pits left behind. Because pitting paves the way for further corrosion, the only way to restore the metal to its previously non-rusted state is to grind the surface until it is uniformly smooth. In some cases, rust that penetrates deeply makes this impossible. The dimensional stability of the metal has likely suffered, and it should be swapped out with a new product for the sake of safety and performance.

Manual Rust Removal

When rust progresses past the surface layer to a depth that makes rust removal solvent an inefficient option, manual rust removal is the option of choice. Using a special grinding pad or a sandblaster made for treating metal, the accumulation can be removed quickly.

However, you encounter one of the same results of using an industrial solvent: After grinding or sandblasting are finished, the surface is uneven, dipping in the place rust once occupied. Again, regulating the surface by making it uniformly even is a key to preventing further corrosion, preserving appearance, and supporting dimensional stability.

Need to Remove Rust?

If so, and the rust hasn’t progressed past the surface layer to cause prominent pitting, using an industrial rust removal solvent is usually the best option — and Rust Rip from Ecolink is one of the best solvent based, industrial rust removal solutions on the market.

Rust Rip causes thin accumulations of rust to disintegrate and flow away from the metal’s surface. You may need to mechanically treat the area where rust accumulated to make it homogenous with the rest of the metal’s appearance and corrosion resistance. If you remove causes of rust in the work environment, you may never need to remove rust from metal parts and equipment again, depending on the metal’s age and how it is used.

To learn more about Rust Rip and other industrial rust removal options from Ecolink, please call us today at 800-563-1305, or send us an email through our contact form. We look forward to helping you keep your business-critical equipment and parts rust-free!