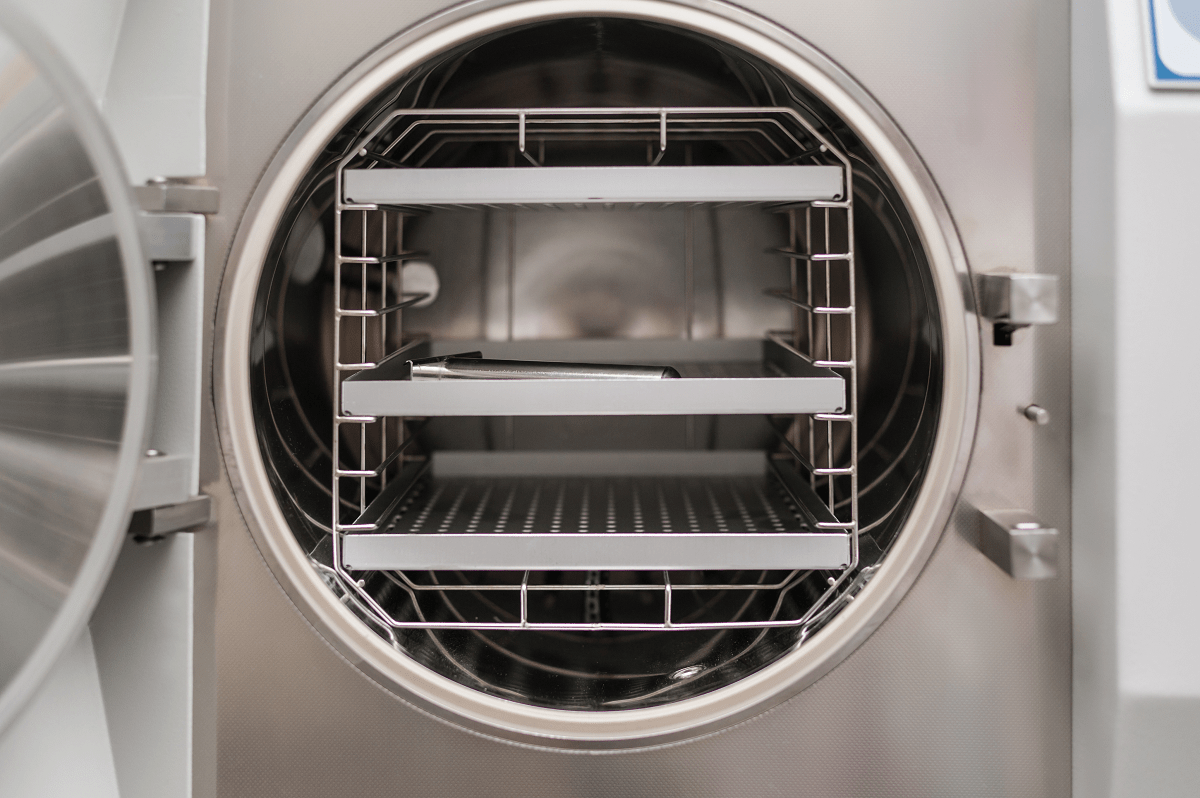

An industrial parts washer is a significant investment. Consequently, first-time buyers often have questions concerning which kind of parts washing system they should target: a hot tank parts washer or a cold tank parts washer. The answer depends on the parts washing needs and goals of the user.

In this entry, we focus on commonly asked questions about hot tank parts washers to help you decide if they’re a good option for your parts washing requirements.

- Are hot tank parts washers the same as aqueous based parts washers?

In most cases, the answer is yes. Hot tank parts washers are typically aqueous based parts washers. This is because aqueous parts washing cleaners require hot water to dissolve the cleaning detergent — a combined process that produces the stringent cleaning action.

- What method of operation does a hot tank parts washer use to clean parts?

Each model is a different regarding construction and features, but hot tank washers generally operate in the following way: water and detergent are combined with heat to dissolve the detergent, then the parts washer performs a mechanical action often compared to a dish washer’s. The type of detergent used and length of the wash cycle determine the end result.

- Do hot tank parts washers make parts cleaner than cold tank washers?

It depends on what type of accumulation you need to remove. Cold tank washers generally use solvent based cleaners, which are designed to deliver chemical cleaning power without the need for heat; while hot tank washers use detergent that requires heat to achieve good efficacy. The goal is to match the parts cleaning job with the proper parts washer and cleaning agent.

- Do hot tank washers use the jet spray process or power wash process?

Hot tank washers use jet spray action or power wash action. The process used impacts the type of detergent used, how much detergent is used, the temperature to which water is heated, and the mechanical energy produced to perform the jet spray or power wash function.

- Does jet spray action offer better cleaning than power wash, or vice versa?

Wikipedia provides a succinct answer: “The power wash process is superior to the jet spray process for faster, more thorough parts cleaning cycles while minimizing detergent use and waste generation. The power wash process is generally effective for difficult soil removal applications, such as burnt hydrocarbons, paint, scale, varnish, carbon, mastic, or rubber.”

- Why should I purchase solvents for a hot tank parts washer from Ecolink?

There are several reasons to make Ecolink your supplier. We provide eco friendly stock solutions and custom solutions for hot tank parts washers. If a stock product isn’t a perfect match for your needs, we’ll create a custom solvent tailored to your requirements. In addition, we provide free test samples, so you can try a cleaner to see how it works.

To place an order or request information, please call us today at 800-563-1305, or use our contact form. We look forward to helping you select the right cleaner for your parts washing needs.