Ready to save a bundle? Unbundle your integrated chemical sourcing, service and/or disposal contract(s)

Granted there are too few national hazardous waste hauling and recycling companies to choose from. But why are there so many customers under contract dissatisfied (less than 80% happy) and where do they go for help? Those unhappy have few or no options for turnkey [i.e. bundled] industrial chemical sourcing, parts washing equipment maintenance ‘and’ hazardous waste disposal. Until now, Ecolink Inc, decided to take action and issued a $100 Million Challenge to help governments and industry reduce their total cost of chemical ownership including associated chemical waste and pollution.

Ecolink flipped the funnel electing to focus at the front of the pipe (source reduction) rather than the end of the pipe (chemical recycling and disposal) and thus reengineered the entire process – material, method, machine and people. Ecolink first improved the parts washing chemicals involved moving away from stinky Mineral Spirits (also known as Stoddard Solvent) in favor of high flashpoint, odorless alternatives or low VOC options, including MIL-PRF-680C, Type V. Next, Ecolink worked with leading parts washing equipment experts to leverage gravity-fed baffle systems that separate liquids from solids (sludge, drag-out) inside the parts washing unit. Ecolink and their equipment and filtration partners employ high efficiency filtration (0.5 micron) to extend the life of the parts washing solvent in use. As a result you are able to ‘easily’ manually meter out as little as 2-5 gallons of sludge from a standard 25-gallon holding capacity which translates into fewer visits, fewer gallons recycled/disposed/landfilled/incinerated and A LOT fewer dollars. One of Ecolink’s clients reduced their annual chemical usage from 660 gallons (12 x 55-gal drums) down to 1 x 55-gallon drum in one of their shops using a high-efficiency parts washing system. At a cost of ~ $1,000 per drum to purchase the chemical and an additional ~ $100 per drum to dispose of each drum, the client was able to save more than $12,000 annually in just one shop and were able to easily manage and maintain their new and improved parts washing unit. Ecolink developed a ridiculously simple refiltration method that most people can operate for additional filtration within the parts washing system at 3-5 gallons-per-minute (GPM).

Ready to save a bundle? Call 800 563-1305 or email to explore all your options for unbundling current sourcing, service or disposal contract(s).

One of Ecolink’s U.S. military clients reduced their annual disposal of hazardous waste by over 13 tons through the implementation of 50 high-performance solvent parts washers. In addition to smarter equipment, the military personnel received detailed material handling and equipment operations training. Annual savings documented exceed $100,000/year on chemical sourcing as well as reduced cost and risk exposure for material handling, freight, disposal, reporting and tracking.

Most of our technologies and techniques will work with your existing solvent-based parts washing systems. Examples include Graymills (offer solvent and aqueous-based parts washers), Inland Technologies Inc. and System One®. Aqueous or water-based systems we can cost-effectively convert to solvent-based parts washing systems include: Hotsy®, Hydro-Blast™ Inc, The MART Corporation, Mirachem, Proceco, Temco and UniWashers. Factoring currently high and continuously rising petroleum prices, the payback for a new parts washing unit is less than 6 months for moderate to high usage shops and even faster when using high-value, low VOC solvents such as MIL-PRF-680C, Type V.

For large-scale military installations and heavy industrial maintenance operations such as Metals & Mining, the annual savings potential are tremendous. Because these high-efficiency parts washing units are well made in USA, they last a very long time with minimal maintenance required when adhering to manufacturer’s recommended care. With over 1,800 units in operation within the US Department of Defense, many over 10 years of continued use, there are impressive Return-On-Investment (ROI) documented. One major US Army installation has saved more than $700,000 per year or more than $7 Million not including disposal and reporting fees that were avoided.

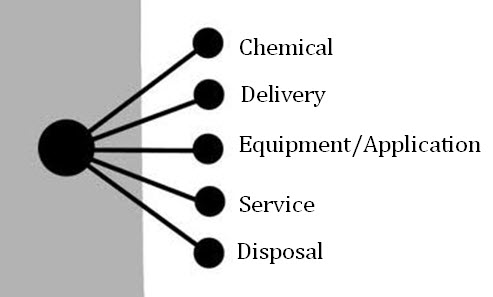

Other ways we make it easy to unbundle from your current provider, clean up your budget and normalize your operating expenses:

- Magnetic MSDS affixed to each parts washing units making it easy to call to treat spills or exposure, replenish solvent and enhance your regulatory compliance efforts during inspections

- Training – we offer a combination of on-site and on-line

- Hazardous Waste Brokerage – we have a referral network of hazardous waste haulers to cart away the sludge, drag-out

- Parts Washing Equipment installation and maintenance – we have a service provider that can set up and maintain your equipment if you prefer not to do it yourself

- Financing – we offer leasing and flexible financing terms to accelerate savings and results

- Consulting, facilitation – we work with your team to customize your change-out schedule for each unit based on soil load & frequency so you know exact amount of annual time (internal or external) your parts washing portion of operation requires as well as document and customize operating and maintenance procedures specific to your goals and internal policies

Seldom can a contract reveal the true or entire cost of their services. Checking their drivers/technicians in and out of your facility, waiting for them to pump in recycled solvent and return again to pump out dirty solvent, getting parts washing serviced too soon or too late, and negotiating contracts consume valuable time and money not reflected in the fine print. Combined all of this can lead to non-sustaining repetitive cycles and a distorted pattern of supply geared toward resuming old, unbalanced, and unsustainable pattern of growth. By contrast, when few(er) chemicals are delivered and taken from your parts washing systems multiplied by your number of locations then less polluted chemical are put into our environment. Leveraging proven technologies to make government and businesses cleaner, and simple solutions that lessen the environmental impact is less of a gamble. Why not try less clean chemicals taken out; less polluted chemicals put back…one drum at a time? It can only help improve the quality of your relationships with regulators, rule makers

Checks & Balances – Unbundling All-Inclusive Contracts

When the supplier and disposal company are one and same, how can you expect to ever use less chemicals? Owning both ends of the noodle offers no incentive to reduce your chemical throughput. You can easily save 35% by simply conducting in process recycling with your existing parts washing equipment and without an inflexible contract. When advice/service is one-sided how can there be a win-win? Worse, you are in danger of losing entire supply chains and human capital that goes with it if anything happens to your driver/technician. High turnover is a huge risk over the duration of your contract.

Cancelling Your Current Contract

Step 1: Read the fine print to explore any buy-out clause or early cancellation penalty.

Step 2: Email or call us at 800 563-1305 to unbundle your existing scope of work to determine your best case scenario

Step 3: Decide which parts you want to do yourself and which parts you want to outsource for Ecolink to handle.

Step 4: For the parts you want to outsource, decide on performance contracting where both organizations share in the savings generated OR flat fee for product and service.

Step 5: Explore all funding streams, financing (tax credits, green loans) to implement plan

Step 6: Spend less time on paperwork and more uninterrupted time…