Removing Carbon Deposits from Stator Bars, Stator Motors

Stator bar insulation failures

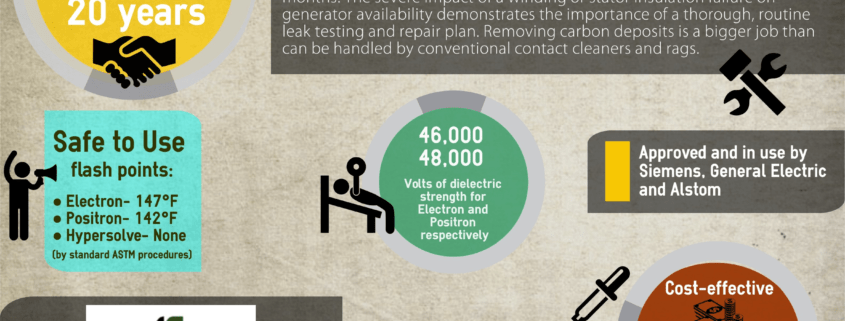

Stator bar insulation failures often occur as a result of carbon deposits. If a failure occurs while in service it can cause extensive collateral damage to the generator stator core and field, which can extend a forced outage several months. The severe impact of a winding or stator insulation failure on generator availability demonstrates the importance of a thorough, routine leak testing and repair plan. Removing carbon deposits is a bigger job than can be handled by conventional contact cleaners and rags. Industrial degreasers such as Ecolink’s flagship products, Electron and Positron, have been in use for this very application for over 20 years. Approved and in use by Siemens, General Electric and Alstom, these solvent degreasers deliver incredible cleaning performance while also easy to work with including high flash point (above 140°F), high dielectric strength (46,000 volts) and no surface leakage of current in immediate residue tests. More importantly they are very cost-effective saving money on inbound shipping, freight and outbound disposal costs.

Stator Rewinds

Typical field service scope for a stator rewind installation will include:

- Stator core preparation, including cleaning, repairs to interlaminar insulation, testing and re-painting. (Some scopes may include a core restack. In other cases, age of the unit or testing results may indicate problems requiring a core replacement.)

- Installation of upgraded end winding support system (Certain fossil units).

- Installation of new surge and bus rings ( may include provisions for a future Main-Neutral Interchange).

- Installation of stator bars, RTDs and wedging and blocking system and testing of individual coils or groups of coils at specified points in the installation.

- Brazing and circuit connections

- Testing of the completed winding

- Painting and miscellaneous finishing details

Special Offer for Stator Bar, Stator Motor Maintenance

Ecolink Inc. is offering a 15% discount for any cleaner degreasers, degreaser chemicals or industrial solvent manufactured or distributed by Ecolink Inc.

We offer numerous alternatives to:

|

|

|

|

|

|

|

Call 800 886-8240 or email info@ecolink.com to discuss your current use of any of these or other manufacturer’s brand to switch and start saving. With over 200 products to choose from, including several new formulations not yet listed on the website, we feel certain we can expand upon the savings and safety improvements enjoyed for nearly 20 years. Chemist owned and operated, we offer guaranteed FREE samples, including FREE freight, to evaluate for a RISK-FREE evaluation.

Stator Bar, Stator Motor related articles

- Armature Rewinding: Degreasing Damaged Coils, Stators (ecolink.com)