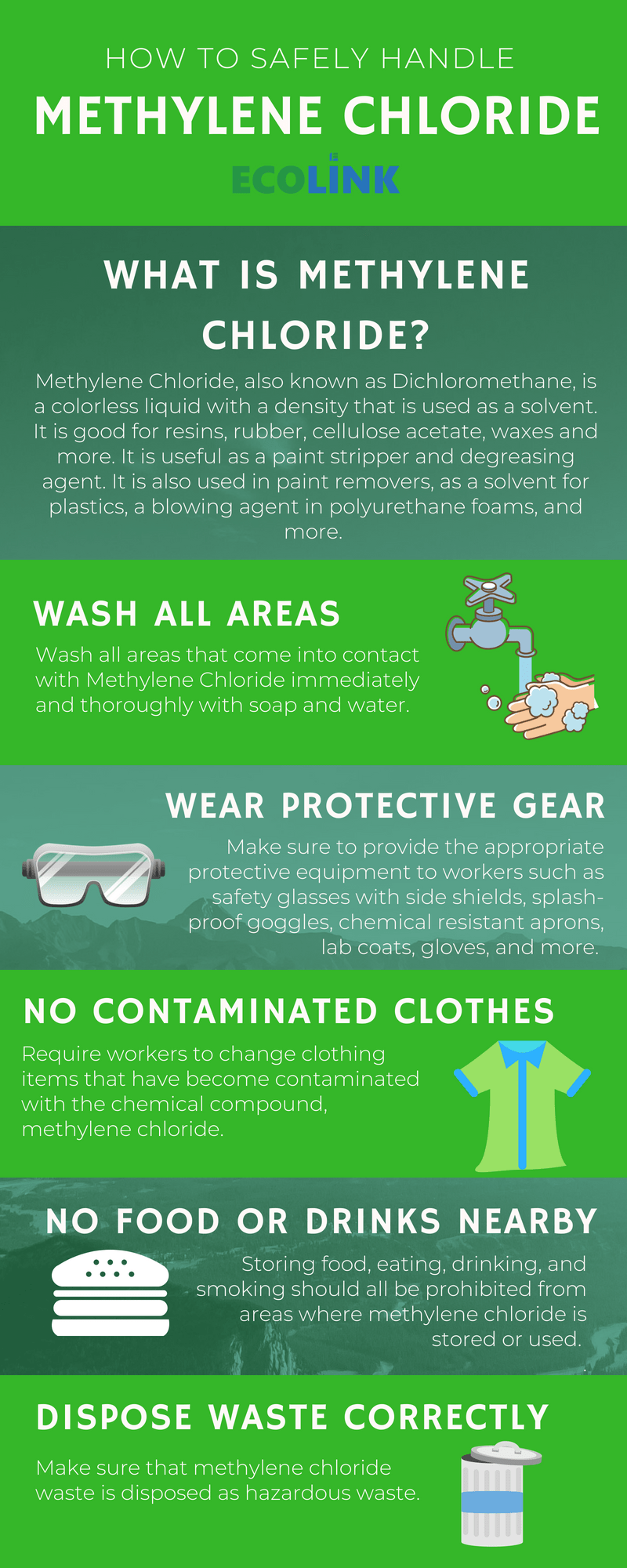

Methylene Chloride, also known as Dichloromethane, is a colorless liquid with a density that is heavier than water. Methylene Chloride is used as a solvent and is good for resins, rubber, cellulose acetate, waxes and more. It is useful as a paint stripper and degreasing agent. It is also used in paint removers, as a solvent for plastics, a blowing agent in polyurethane foams, and more. While Methylene Chloride can be useful for a variety of industries, it is also viewed as a potential occupational carcinogen by several organizations such as the National Institute for Occupational Health and Safety and the Occupational Safety and Health Administration due to the compound being volatile.

Dichloromethane Risks

Dichloromethane has significant chronic exposure hazards with one being human carcinogenicity. Exposure to methylene chloride can affect not only create a health hazard for workers but also can create a safety hazard since extreme temperatures can cause closed containers to explode. Inhaling methylene chloride could cause symptoms such as lightheadedness, headaches, vomiting, and even nausea. If exposed to methylene chloride, exposure could cause chest pains. Skin contact may cause irritation and even skin burns if the chemical remains on the skin.

Here are some guidelines on how to work safely with methylene chloride, also known as dichloromethane, to ensure safe work environments:

- Wash all areas that come into contact with Methylene Chloride immediately and thoroughly with soap and water.

- Make sure to provide the appropriate protective equipment to workers such as safety glasses with side shields, splash-proof goggles, chemical resistant aprons, lab coats, gloves, and more.

- Require workers to change clothing items that have become contaminated with the chemical compound, methylene chloride.

- Employ effective engineering controls, good work practices, and proper maintenance procedures.

- Storing food, eating, drinking, and smoking should all be prohibited from areas where methylene chloride is stored or used.

- Make sure that methylene chloride waste is disposed of as hazardous waste.

Interested In Purchasing Methylene Chloride also known as Dichloromethane?

Make sure to practice these safe handling tips to ensure that you and your organization are working safely with methylene chloride, also known as dichloromethane. If you’re in the market for Methylene Chloride, please call us today at (800) 563-1305, send us an email through our contact form, or shop online here. For over 25 years, we’ve provided stock and custom cleaners that have an amazing efficacy. We look forward to hearing from you and seeing how we can help with all of your solvent needs!