Bromopropane Replacements: Switch to FluoSolv®

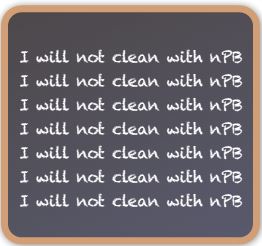

Two years ago, the National Toxicology Program (NTC) and a panel of scientific experts voted unanimously to categorize 1-bromopropane (a.k.a n-propyl bromide) as “reasonably anticipated to be a human carcinogen.” No studies have measured the carcinogenic effects of it on humans, but the solution has been observed to produce negative neurological effects in people, such as headaches, profound dizziness, loss of consciousness, slurred speech, and difficulty walking.

To make matters worse, these conditions may not cease when exposure to 1-bromopropane is discontinued. Because chronic exposure the solution can cause permanent neurological damage, those who are chronically exposed to, and suffer permanent disability as a result, often file liability lawsuits against their employers, particularly because the damage has permanently reduced their earning capacity and exposed them to a high level of pain and suffering.

Bromopropane Replacements

The negative neurological effects that 1-Bromopropane produces in humans, as well as its toxic effect on the environment, should make companies that frequently use the solution look for bromopropane replacements. Several products are marketed as bromopropane replacements, but not all of them have an excellent safety profile. FluoSolv® — a line of proprietary solutions from EcoLink — is an example of a Bromopropane replacement that has a great safety profile.

For most large-scale users of 1-bromopropane, the primary goal of finding a replacement is to select one that performs with the same power as 1-bromopropane but is formulated to be safer for humans and the environment. If your company frequently uses 1-bromopropane for any of the following applications, replacing the solution with FluoSolv® is an efficient way to transition a toxic work environment into one that poses fewer health risks and is better for the environment.

- Vapor immersion operations

- Degreasing operations

- Adhesive spray applications

- Dry cleaning

- Aircraft maintenance

- Asphalt production

- Synthetic fiber manufacturing

FluoSolv® products are formulated to be drop-in solutions for the replacement of brominated solvents, as well as chlorinated solvents, chlorofluorocarbon solvents, and hydrochlorofluorocarbon solvents. Unlike products that contain these ingredients, FluoSolv® solutions are formulated with azeotropic fluorinated fluids and trans-dichloroethylene (t-DCE) that are non-flammable, non-hazardous, non-ozone depleting, and protect workers from the neurotoxic effects that result from incidental or chronic contact with 1-bromopropane.

FluoSolv® products are used in a variety of industries by companies that need bromopropane replacements, including: aerospace and military, metal finishing, electronics manufacturing and maintenance, oil and gas, optics and fiber optics maintenance, semiconductor/SMT/wave maintenance, transportation and transit maintenance, medical tool cleaning, and general industrial cleaning. We will help you choose the right FluoSolv® products for your needs.

Place Your Order Today

If your company needs a drop-in solution for replacing 1-bromopropane products, our line of FluoSolv® solutions make excellent bromopropane replacements. If you need assistance choosing a FluoSolv® product that meets the requirements of 1-bromopropane in the capacity that you use it, call us today at (800) 563-1305, or fill out the contact form on our website. We look forward to providing you with a solution that is safe for your workers and the environment.