Industrial IPA Solvent Suppliers: Questions to Ask Before You Buy

There are lots of isopropyl alcohol (IPA) suppliers out there. Having such an extensive range of options is nice from a customer standpoint, but it can also make the supplier selection process last longer than anticipated.

There are lots of isopropyl alcohol (IPA) suppliers out there. Having such an extensive range of options is nice from a customer standpoint, but it can also make the supplier selection process last longer than anticipated.

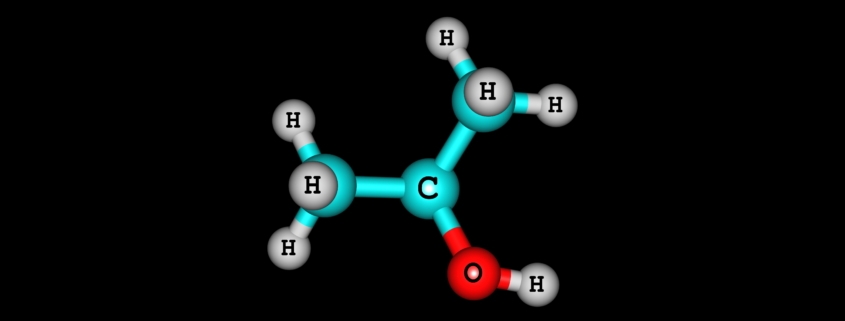

If you need industrial strength IPA — which generally has a purity of at least 99% — crossing suppliers of commercial grade and consumer grade IPA off the list, and limiting your choices to industrial IPA suppliers, is an easy way to narrow your field of options. You can refine your selection of IPA solvent suppliers further by asking the following five questions.

- Is formulating custom IPA solvents an option?

Working with IPA solvent suppliers that offer custom formulations is highly recommended. It helps prevent ordering a stock solution that works well in some respects but not in others. This problem is easily avoided when you work with a custom solvent supplier.

- What is the turnaround time for custom IPA solvents?

The chance to order custom solvents is a great option, but the ultimate value is determined largely by how quickly you can receive a custom order. If productivity is at stake, find out the maximum turnaround time for a custom solvent shipment before placing the order.

- Is it possible to get a free test sample prior to purchase?

The last thing you want is a large supply of IPA solvent that doesn’t work as well as expected. The surest way to keep it from happening is requesting a free test sample before placing an order. Ecolink provides a free test sample for each of our solvents.

- Are your containers designed to prevent IPA evaporation?

It’s relatively common phenomenon: An organization orders 99% pure IPA, and then finds the purity is lower after receiving the order and testing its IPA density. What happened? There’s a good chance the IPA container is to blame. Unless the seal is designed to withstand the vapor pressure of IPA, the alcohol can evaporate and weaken the formulation.

- Do your solvents contain ingredients scheduled for regulation?

Solvent ingredients the Environmental Protection Agency (EPA) regulates can’t be used in quantities that most large-scale users require. Consequently, ordering from IPA solvent suppliers whose products contain ingredients that are scheduled for regulation is like living on borrowed time. IPA solvent suppliers that offer environmentally-prefered solvents is the best option.

Contact Us Today

Ecolike is one of your best options among IPA solvent suppliers for several reasons, including the availability of both stock and custom IPA formulations, the availability of environmentally preferred solutions whose ingredients aren’t regulated by the EPA, and the option to order practically any volume of IPA, on any supply schedule, just to name a few.

To place an order for IPA solvent, or to learn about additional advantages of choosing us over other IPA solvent suppliers, please contact us today by calling 800-563-1305, or send us an email using the contact form on our website. We take pride in supplying best-in-class industrial IPA solvents!